Abstract

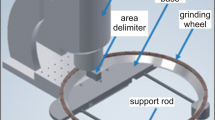

Fine-grained resin bonded diamond tools are often used for ultra-precision machining of brittle materials to achieve optical surfaces. A well-known drawback is the high tool wear. Therefore, grinding processes need to be developed exhibiting less wear and higher profitability. Consequently, the presented work focuses on conditioning a mono-layered, coarse-grained diamond grinding wheel with a spherical profile and an average grain size of 301 µm by combining a thermo-chemical and a mechanical-abrasive dressing technique. This processing leads to a run-out error of the grinding wheel in a low-micrometer range. Additionally, the thermo-chemical dressing leads to flattened grains, which supports the generation of hydrostatic pressure in the cutting zone and enables ductile-mode grinding of hard and brittle materials. After dressing, the application characteristics of coarse-grained diamond grinding wheels were examined by grinding optical glasses, fused silica and glass–ceramics in two different kinematics, plunge-cut surface grinding and cross grinding. For plunge-cut surface grinding, a critical depth of cut and surface roughness were determined and for cross-grinding experiments the subsurface damage was analyzed additionally. Finally, the identified parameters for ductile-machining with coarse-grained diamond grinding wheels were used for grinding a surface of 2000 mm2 in glass–ceramics.

Similar content being viewed by others

References

Brinksmeier E, Mutluguenes Y, Klocke F, Aurich JC, Shore P, Ohmori H (2010) Ultra-precision Grinding. CIRP Ann Manuf Technol 59:652–671. doi:10.1016/j.cirp.2010.05.001

Bifano TG, Dow TA, Scattergood RO (1991) Ductile-regime grinding: a new technology for machining brittle materials. Trans ASME J Eng Ind 113:184–189

Lawn BR, Jensen T, Aurora A (1976) Brittleness as an indentation size effect. J Mater Sci Lett 11:575

Marshall DB, Lawn BR (1986) Indentation of Brittle Materials. Microindentation Techniques in Materials Science and Engineering, ASTM STP 889. In: Blau PJ, Lawn BR (eds) ASTM, Philadelphia, pp 26–46

Biermann D, Wuerz E (2009) A study of grinding silicon nitride and cemented carbide materials with diamond grinding wheels. Prod Eng Res Devel 3(4):411–416. doi:10.1007/s11740-009-0183-z

Rickens K, Grimme D, Riemer O, Brinksmeier E (2006) Engineered diamond wheels for precision ductile grinding. Prod Eng Res Devel 13(2):275–280

Zhao Q (2015) Ultra-precision grinding of optical glasses using mono-layer nickel electroplated coarse-grained diamond wheels. Part 1: ELID assisted precision conditioning of grinding wheels. Precis Eng 39:56–66. doi:10.1016/j.precisioneng.2014.07.006

Bing G, Zhao Q, Xiaoyan F (2014) Precision grinding of optical glass with laser micro-structured coarse-grained diamond wheels. J Mater Process Technol 214:1045–1051. doi:10.1016/j.jmatprotec.2013.12.013

Brinksmeier E, Mutluguenes Y, Riemer O (2013) Dressing of coarse grained diamond grinding wheels utilizing the thermo-chemical reaction. Proc Euspen Int Conf 2:125–128

Marinescu ID, Hitchiner M, Uhlmann E, Rowe WB, Inasaki I (2007) Handbook of machining with grinding wheels. CRC Press, Boca Raton, pp 270–278

Heinzel C, Rickens K (2009) Engineered wheels for grinding of optical glass. Ann CIRP 58(1):315–318. doi:10.1016/j.cirp.2009.03.096

Zou L, Dong G, Zhou M (2013) Investigation on frictional wear of single crystal diamond against ferrous metals. Int J Refract Metal Hard Mater 41:174–179. doi:10.1016/j.ijrmhm.2013.03.008

Shimada S, Tanaka H, Higuchi M, Yamaguchi T, Honda S, Obata K (2004) Thermo-chemical wear mechanism of diamond tool in machining of ferrous metals. Ann. CIRP 53(1):57–60. doi:10.1016/S0007-8506(07)60644-1

Brinksmeier E, Heinzel C, Rickens K, Althoff M, Berger D (2016) Präzisionsschleifen mit groben Diamantkörnern. wt Werkstattstechnik 6:387–393

Contardi C, Taylor ER, Fu A (2001) Study of UV-written channels in lead silicate glasses. J Non-Cryst Solids 291:113–120. doi:10.1016/S0022-3093(01)00796-7

Heiman D, Hamilton DS, Hellwarth RW (1979) Brillouin scattering measurements on optical glasses. Phys Rev B (Condensed Matter) 19(12):6583–6592

Scholze H (1988) Glas. Natur, Struktur und Eigenschaften. Springer, Berlin, p 213. ISBN 3-540-18977-7

Wray JH, Neu JT (1969) Refractive index of several glasses as a function of wavelength and temperature. J Opt Soc Am 59:774–776

Sun X, Stephenson DJ, Ohnishi O, Baldwin A (2006) An investigation into parallel and cross grinding of BK7 glass. Prec Eng 30:145–153. doi:10.1016/j.precisioneng.2005.07.001

Acknowledgments

The authors would like to thank the German Research Foundation (Deutsche Forschungsgemeinschaft DFG) for funding the project “Engineered Grinding Wheels”—Deterministisches Präzisionsschleifen optischer Gläser (#BR 825/53-3).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brinksmeier, E., Riemer, O., Rickens, K. et al. Application potential of coarse-grained diamond grinding wheels for precision grinding of optical materials. Prod. Eng. Res. Devel. 10, 563–573 (2016). https://doi.org/10.1007/s11740-016-0699-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0699-y