Abstract

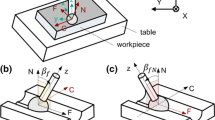

Modern 5-axis machining centers enable the development and use of new machining kinematics and grinding strategies to grind workpieces with superabrasives mounted points. One of these technologies is the oscillating surface grinding (OSG), which can improve the surface characteristics and the tribological properties of machined surfaces. In the current contribution could be observed that the resultant surface roughness values by OSG are not constant within a wavelength of oscillation of the grinding tool. This leads to further studies of the kinematics involved in this process, resulting in the development of a new grinding strategy: the tilt surface grinding (TSG). By using TSG, workpiece surfaces with similar characteristics as OSG could be obtained even without aid of oscillation. In this study, experimental tests are carried out to investigate the influence of parameters involved in these strategies. A significant parameter is the tilt angle α t, which can be simplified as an angle between the directions of the feed rate in tangential direction v ft and the feed rate in axial direction v fa of the grinding tool. The tilt angle α t is responsible for changes occurred on the OSG when compared to conventional surface grinding. Increasing the tilt angle α t, a reduction up to 50 % of the roughness values could be achieved. This paper aims to complement and expand the knowledge of the OSG, explaining how the aid of the oscillation tool changes the grinding kinematic, in order to optimize the grinding process.

Similar content being viewed by others

References

Uhlmann E, Mewis J, Hochschild L (2010) Analyse von Schleifprozessen mit genuteten Schleifscheiben. wt Werkstattstechnik online 100/6:494–501

Uhlmann E, Sammler C (2010) Ressourceneffizientes Schleifen – Lösungen und Grenzen. In: Tawakoli T (ed) Moderne Schleiftechnologie und Feinstbearbeitung

Uhlmann E, Mewis J, Kirchgatter M (2010) Dynamiksimulation von Schleifprozessen. wt Werkstattstechnik online 100/1/2:53–61Vulkan, Essen

Kirchgatter M (2010) Einsatzverhalten genuteter CBN-Schleifscheiben in keramischer Bindung beim Außenrund-Einstechschleifen. Technische Universität Berlin, Dissertation

Uhlmann E, Borsoi Klein T, Hochschild L, Bäcker C (2011) Influence of structuring by abrasive machining on the tribological properties of workpiece surfaces. In: Procedia engineering, 1st CIRP conference on surface integrity (CSI), 19: 363–370

Kaiser M (1977) Tiefschleifen von Hartmetall. Technischer Verlag Resch (Fertigungstechnische Berichte)

Uhlmann E (1994) Tiefschleifen hochfester keramischer Werkstoffe. Randzoneneigenschaften. Technische Universität Berlin, Dissertation

Marinescu ID, Hitchiner M, Uhlmann E, Rowe WB, Inasaki I (2006) Handbook of machining with grinding wheels. CRC Press, NY. ISBN 978-1-57444-671-5

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Uhlmann, E., Borsoi Klein, T. & Koprowski, S. Tilt angle effects in surface grinding with mounted points. Prod. Eng. Res. Devel. 8, 431–442 (2014). https://doi.org/10.1007/s11740-014-0540-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0540-4