Abstract

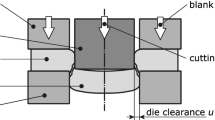

During the process of high speed cutting (HSC), fast rotating milling cutters are subject to much higher centrifugal forces than cutting forces. This fundamental factor requires to take into account more stringent safety considerations when working on the concept and design of HSC tools. This paper focuses on the operational safety and speed limit of commonly used HSC milling head cutters with indexable inserts being clamped by high-strength countersunk head screws. The spin burst test results of those tools with radial and tangential insert connections are summarized. The analytical formulas to estimate the failure speeds of both insert connections are developed and discussed based on theoretical analysis on insert connection mechanism. Calculation results show a good correlation with the experimental results from spin burst tests. Finally, a new analytical-empirical approach to determine the speed limits and maximum permissible rotational speeds of both types of tools based on a high confidence level is presented. The approach proposed is suggested for a reliable estimate of the speed limits and maximum permissible rotational speeds for fast rotating tools with screwed radial or tangential indexable inserts.

Similar content being viewed by others

References

Würz T (1999) Sicherheit schnelldrehender Fräswerkzeuge. Dissertation, Technical University of Darmstadt

ISO 15641: 2001 (2001) Milling cutters for high speed machining—safety requirements

Abele E, Hölscher R, Hohenstein J (2008) Methodology for evaluation of centrifugal force resistance of HSC-tools by analyzing tool body deformation and cutting edge offset. CIRP Ann Manuf Technol 57(1):117–120

Barthelmä F, Aschenbach B, Simon R (1995) Werkzeuge für die HSC-Bearbeitung, Untersuchungen zum dynamischen Schneidenversatz an Zerspanungswerkzeugen mit geometrisch bestimmter Schneide. wt-Produktion und Management 85:523–528

Barthelmä F, Aschenbach B (1996) Bestimmung des absoluten dynamischen Versatzes an Hochgeschwindigkeits-Fräswerkzeugen. in Tagungsband: 2. Schmalkalder Werkzeugtagung, GFE/FH Schmalkalden

Leopold J, Schmidt G, Kieninger A (2000) FEM-Analyse modular aufgebauter HSC-Fräswerkzeuge mit 3-D einstellbaren Schneiden. DIMA 54(2):54–59

Leopold J, Schmidt G, Hoyer K (1998) Sicherheit von HSC-Werkzeugen. Werkstatt und Betrieb 131(1):82–86

Schulz H, Würz T, Huerkamp W, Leopold J (1997) Safety concepts for tools for high speed machining. Prod Eng 4(2):143–148

ISO 11529-2: 2005 (2007) Milling cutters—designation—Part 2: shank-type and bore-type milling cutters with indexable inserts

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abele, E., Tian, J. Estimation of the rotational speed limit of milling cutters with screwed indexable inserts. Prod. Eng. Res. Devel. 8, 111–119 (2014). https://doi.org/10.1007/s11740-013-0495-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0495-x