Abstract

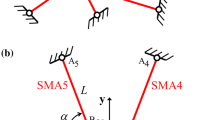

Feed axis for small machine tools usually need separate guidance elements since they cannot carry transversal loads. Hence, cross section and mass as well as the complexity of the feed axis system increase. In this paper a new Shape Memory Alloy (SMA) actuator approach, which does not need additional guidance elements is presented. The principle is based on the telescoping of several concentrically arranged tube-shaped elements. These are interconnected by SMA-wires to obtain a cumulative relative movement of the stages caused by contraction of the single wires. An increasing number of stages lead to an increasing actuator stroke without affecting its length. Due to the angular orientation of the wires the force is split into longitudinal and transversal components. Thus, no further guidance elements are needed. To investigate the actuating principle theoretically a multi-domain-model is developed. It enables to derive correlations between design- and specified parameters. Furthermore a new control approach for antagonistically arranged SMA actuators is presented. It is based on the combination of the metrological and model-based detection of the gradient of the composition-temperature characteristics. With the adaption of the control parameters a stroke-independent dynamic behavior should be realized

Similar content being viewed by others

References

Wulfsberg JP, Grimske S, Kohrs P, Kong N (2010) Kleine Werkzeugmaschinen für kleine Werkstücke. wt-Werkstattstechnik online 100

Smith ST, Seugling RM (2008) Sensor and actuator considerations for precision, small machines. Precis Eng 30:245–264

Kohl M (2002) Entwicklung von Mikroaktoren aus Formgedächtnislegierungen. Dissertation, Forschungszentrum Karlsruhe

Patent: WO 03/095798 A1

Jansen S, Breidert J, Welp EG (2001) Positioning actuator based on shape memory wires. In: 9th international conference on new actuators (Actuator) pp. 94–97

Schiedeck F (2009) Entwicklung eines Models für Formgedächtnisaktoren im geregelten dynamischen Betrieb. Dissertation, Leibnitz Universität Hannover

Kunze H, Bucht A, Pagel K, Zerneke A (2011) Leichte Formgedächtnisaktoren im Automobil. ATZ 04:266–271

Redmond JA, Brei D, Luntz J, Browne AL, Johnson NL (2011) Spool-packaging of shape memory alloy actuators: Performance model and experimental validation. J Intell Mater Syst Struct 23:201–219

Sofla AY, Elzey DM, Wadley HN (2007) Two-way antagonistic shape actuation based on the one-way shape memory effect. J Intell Mater Syst Struct 00:1–12

Neugebauer R, Drossel WG, Pagel K, Bucht A, Anders N (2011) Design of a controllable shape-memory-actuator with mechanical lock function. SPIE Proceedings

Neugebauer R, Pagel K, Bucht A, Drossel WG (2012) Model-based position control of shape memory alloy actuators. Int J Mechatron Manuf Syst 5:93–105

Mertmann M (1997) NiTi-Formgedächtnislegierungen für Aktoren der Greifertechnik: Funktionelle Eigenschaften und Optimierung. VDI-Verlag

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pagel, K., Drossel, WG. & Zorn, W. Multi-functional Shape-Memory-Actuator with guidance function. Prod. Eng. Res. Devel. 7, 491–496 (2013). https://doi.org/10.1007/s11740-013-0463-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0463-5