Abstract

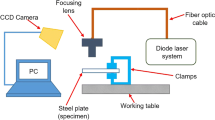

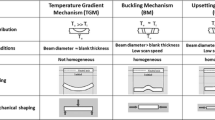

Asymmetric Incremental Sheet Forming (AISF) is a relatively new manufacturing process. In AISF, a CNC driven forming tool imposes a localized plastic deformation as it moves along the contour of the desired part. Thus, the final shape is obtained by a sequence of localized plastic deformations. AISF is suitable for small series production of sheet metal parts as needed in aeronautical and medical applications. Two main process limits restrict the range of application of AISF in these fields. These are the low geometrical accuracy of parts made from titanium alloys or high strength steels and, for titanium alloys, the limited formability at room temperature. In this paper a new concept for laser-assisted AISF is introduced including the required components. Furthermore, the CAX tools used for programming the NC path for the forming tool and the laser spot are illustrated. First experimental results show that the formability of the alloy Ti Grade 5 (TiAl6V4), which is usually used in aeronautic applications, can be increased.

Similar content being viewed by others

References

Jeswiet J et al (2005) Asymmetric single point incremental forming of sheet metal. Annals CIRP 54

Bambach M et al (2009) Strategies to improve the geometric accuracy in asymmetric single point incremental forming. Prod Eng 3:145–156

Ames J (2008) Systematische Untersuchung der Beeinflussung des Werkstoffflusses bei der Inkremetellen Blechumformung mit CNC-Werkzeugmaschinen. Shaker Verlag, Aachen

G. Gottstein (2007) Physikalische Grundlagen der Materialkunde. 3. Aufl. ed. Springer, Berlin [u.a.]

ASM Handbook: metal working (2006) 10 ed. vol 14 B: ASM International

Klocke F, Wehrmeister T (2004) Laser-assisted metal spinnig of advanced materials, presented at the International conference on lasers in manufacturing (LANE), Erlangen

Biermann T et al (2009) Hybrid laser assisted incremental sheet forming: improving formability of Ti- and Mg-based alloys, in International conference on lasers in manufacturing (LiM)

Duflou JR et al (2007) Laser assisted incremental forming: formability and accuracy improvement. Cirp Annals Manuf Techn 56:273–276

Callebaut B et al (2008) Influence of laser assisted incremental forming on residual materials properties in International workshop on thermal forming and welding distorption, Bremen, pp 133–144

Diettrich J (2008) Applikationsangepasste Strahlgeometrie für das Laserstrahl-Löten, ed. Fraunhofer ILT Jahresbericht

Diettrich J (2008) Berarbeitungskopf für das Laserstrahl-Hartlöten mit abschattungsfreier, koaxialer Drahtzufuhr, presented at the Workshop Industrielle Anwendungen von Hochleistungsdiodenlasern, Dresden

Diettrich J et al (2009) Coaxial laser brazing head, in 5. International WLT-conference on lasers in manufacturing, München

Acknowledgments

The authors would like to thank the German Research Foundation DFG for the support of the depicted research within the Cluster of Excellence ‘‘Integrative Production Technology for High-Wage Countries’’. Furthermore we would like to thank our project partners, the Department of Ferrous Metallurgy IEHK, the Welding and Joining Institute ISF, the Fraunhofer Institute for Laser Technology ILT, the Chair for Technology of Optical Systems TOS and our industrial partners EiMA Maschinenbau GmbH and iCASOD GmbH.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Göttmann, A., Diettrich, J., Bergweiler, G. et al. Laser-assisted asymmetric incremental sheet forming of titanium sheet metal parts. Prod. Eng. Res. Devel. 5, 263–271 (2011). https://doi.org/10.1007/s11740-011-0299-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-011-0299-9