Abstract

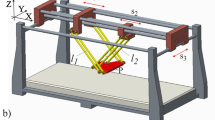

New innovative machine tool concepts like parallel kinematics require the development process to be continuously supported by simulation. Otherwise it will be impossible to exploit their full potential due to the complexity of the kinematic and dynamic behavior. Nevertheless, machine tool manufacturers often refrain from employing simulation tools because of the high effort and expenses expected for the introduction of this technology. It is against this backdrop that the paper presents a method to support the development process of parallel kinematic machine tools with a minimum of effort. An analysis of the development process identifies the machine characteristics that have to be determined for each stage. A simulation method is developed based on these results and on the requirements for a seamless integration of the simulation techniques into the different stages of the process. It is implemented and tested by the example of a parallel kinematic machine tool that has already been successfully introduced in industry.

Similar content being viewed by others

References

Merlet J-P (2000) Parallel Robots. Kluwer Academic Publishers, Dordrecht

Neugebauer R (2006) Parallelkinematische Maschinen–Entwurf, Konstruktion, Anwendung. Springer, New York

NN (1993) VDI-Richtlinie 2221: methodik zum Entwickeln und Konstruieren technischer Systeme und Produkte. VDI—Gesellschaft Entwicklung Konstruktion Vertrieb, Düsseldorf

NN (2004) VDI-Richtlinie 2206: Entwicklungsmethodik für mechatronische Systeme. VDI—Gesellschaft Entwicklung Konstruktion Vertrieb, Düsseldorf

Kirchner J (2000) Mehrkriterielle Optimierung von Parallelkinematiken. Dissertation, TU Chemnitz

Schäfers E, Hamann J, Tröndle H-P (2001) Mechatronische optimierung, analyse und simulation–mechatronic optimization, analysis and simulation of machines. Praxiswissen Automatisierung, Hüthig, Heidelberg, pp 618–628

Wittenburg J (1977) Dynamics of systems of rigid bodies. B.G Teubner, Stuttgart

Munzinger C, Kipfmüller M, Schmidt-Ewig J-P (2008) Simulation of parallel kinematics based on feedback control systems. Conference Proceedings of the 6th CIRP International Conference on Intelligent Computation in Manufacturing Engineering, Naples, Italy, July 23–25

Witt S (2007) Integrierte Simulation von Maschine, Werkstück und spanendem Fertigungsprozess. Dissertation, RWTH Aachen

Hoffmann F (2008) Optimierung der dynamischen Bahngenauigkeit von Werkzeugmaschinen mit der Mehrkörpersimulation. Dissertation, RWTH Aachen

Queins M (2005) Simulation des dynamischen Verhaltens von Werkzeugmaschinen mit Hilfe flexibler Mehrkörpermodelle. Dissertation, RWTH Aachen

Craig RR Jr, Bampton MCC (1968) Coupling of substructures for dynamic analysis. AIAA J 6(7):1313–1319

NN (1999) ECODRIVE03 Antrieb für die allgemeine Automatisierung mit SERCOS-, Analog- und Parallelinterface, Funktionsbeschreibung. Indramat GmbH

Acknowledgments

This paper is based on investigations about reduction of effort during the dynamic simulation of parallel kinematic machine tools which are kindly supported by the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Munzinger, C., Krauße, M. & Kipfmüller, M. Simulation of parallel kinematic machine tools with minimal effort. Prod. Eng. Res. Devel. 4, 491–499 (2010). https://doi.org/10.1007/s11740-010-0259-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0259-9