Abstract

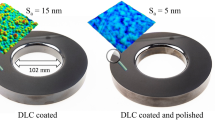

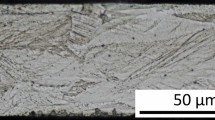

Two different foils out of the alloy aluminium-scandium with a thickness of about 15 μm were produced by the d.c. magnetron-sputtering process applying different substrate temperatures, i.e. S37 at the substrate temperature of 37°C and S160 at the substrate temperature of 160°C. They show different forming properties, e.g. flow stress. In this work these two different foils were used as blank material in micro deep drawing with a punch diameter of 0.75 mm to investigate the formability of these foils. A limit drawing ratio of 1.6 was achieved for both foils. Using the strip drawing test the friction coefficients between the foils and the tools were acquired experimentally, i.e. μ = 0.12 on the smooth side and μ = 0.16 on the rough side for the foil of S37 and μ = 0.15 on the smooth side and μ = 0.17 on the rough side for the foil of S160.

Similar content being viewed by others

References

Geiger M, Kleiner M, Eckstein R, Tiesler N, Engel U (2001) Microforming. CIRP Ann 50(2):445–462

Wicht H, Bouchaud J (2005) Panorama—NEXUS market analysis for MEMS and Microsystems III 2005–2009, MST news—international newsletter on micro-nano integration 5/05: 33–34

Vollertsen F, Biermann D, Hansen HN, Jawahir IS, Kuzman K (2009) Size effects in manufacturing of metallic components. Ann CIRP 58(2):556–587

Tiesler N, Engel U (2000) Microforming—effects of miniaturisation. In: Pietrzyk M, Kusiak J et al (eds) Proceedings of 8th international conference on metal forming, Kraków, pp 355–360

Vollertsen F, Hu Z, Schulze Niehoff H, Theiler C (2004) State of the art in micro forming and investigations into micro deep drawing. J Mater Process Technol 151:70–79

Hirt G, Bambach M, Justinger H, Zhao K (2009) Bedeutung von Groesseneffekten für die Mikro-Blechumformung, Abschlusskolloquium Prozessskalierung, 11./12.Feb.2009 Bonn, Ed. F. Vollertsen, ISBN 978-3-933762-29-0, pp 117–134

Pawelski O (1992) Ways and limits of the theory of similarity in application to problems of physics and metal forming. J Mater Process Technol 34:19–30

Royset J, Ryum N (2005) Scandium in aluminium alloys. Intern Mat Rev 50:19–44

Brookes MG, Kelly PJ, Arnell RD (2004) Mechanical property measurement of titanium/titanium nitride and aluminium-magnesium/magnesium freestanding multilayer foils. Surf Coat Technol 177–178:518–524

Hu Z, Walther R, Vollertsen F (2009) Influence of size effects on the process window for deep drawing, IDDRG 2009. In: Levy BS, Matlock DK, Van Tyne CJ (eds) International conference, June 1–3 2009, Golden/USA. ISBN 978-0-615-29641-8, pp 785–796

Engel U (2006) Tribology in microforming. Wear 260(3):265–273

Hoffmann H, Hong S (2006) Tensile test of very thin sheet metal and determination of flow stress considering the scaling effect. Ann CIRP 55(1):263–266

Schulze Niehoff H (2009) Entwicklung einer hochdynamischen, zweifachwirkenden Mikroumformpresse, Dissertation, Strahltechnik Band 33, BIAS Verlag, Bremen. ISBN 978-3-933762-25-2, 2008

Hu Z (2009) Analyse des tribologischen Groesseneffekts beim Blechumformen, Dissertation, Strahltechnik Band 37, BIAS-Verlag, 2009. ISBN 978-3-933762-30-6

Hu Z, Vollertsen F (2007) Tribological size effects in sheet metal forming. In: Azushima A (ed) International conference on tribology in manufacturing processes, ICTMP2007, Sep. 24–26, 2007, Yokohama, Japan. ISBN 978-4-9903785-0-9, Print SUBARU planning, pp 163–168

Thornton JA (1974) Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J Vac Sci Technol 11:666–670

Cacciamani G, Riani P, Borzone G, Parodi N, Saccone A, Ferro R, Pisch A, Schmid-Fetzer R (1999) Thermodynamic measurements and assessment of the Al-Sc system. Intermetallics 7:101–108

Acknowledgments

The authors thank the Deutsche Forschungsgemeinschaft (DFG) for their beneficial support within the Collaborative Research Centre 747 “Micro Cold Forming” (subprojects A1, B3 and B4).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vollertsen, F., Hu, Z., Stock, HR. et al. On the limit drawing ratio of magnetron sputtered aluminium–scandium foils within micro deep drawing. Prod. Eng. Res. Devel. 4, 451–456 (2010). https://doi.org/10.1007/s11740-010-0229-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0229-2