Abstract

The innovative production methods Composite Extrusion and Friction Stir Welding are used to manufacture lightweight frame structures made of steel reinforced aluminium. In order to optimise the processes themselves and the manufacturing of frame structures both processes are analysed in a structural simulation. One result of these simulations is the distribution of the residual stresses in the reinforced profiles. The simulation results are compared with measurements of the residual stresses by means of neutron scattering.

Similar content being viewed by others

References

Wagner A, Kidratischky H (1987) Verfahren zum Herstellen von Stromschienen sowie Strangpressmatrizen zum Herstellen eines ummantelten Vollprofils. Patentschrift DE 2414178, Aluminium Walzwerke Singen GmbH, Veröffentlichungstag der Patenterteilung: 03 Dec 1987

Thomas WM (1991) Patent WO9310935 (27/11/1992). Improvements relating to Friction Welding 06 Dec 1991

Hammers T, Merzkirch M, Weidenmann KA, Schulze V (2009) Struktur-Eigenschaftsbeziehungen von Fügestellen. In: Tekkaya AE, Baier H, Biermann D, Löhe D, Schulze V, Zaeh MF, Marre M (eds) Integration von Umformen, Trennen und Fügen für die flexible Fertigung von leichten Tragwerkstrukturen. VDI Verlag GmbH, Düsseldorf

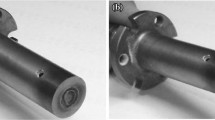

Ruhstorfer M, Zaeh MF (2008) Friction stir welding of steel reinforced aluminium extrusions. In: TWI Ltd (ed) Proceedings of the 7th international symposium on friction stir welding. Awaji-Island, Japan, 20th–22nd May 2008

Schomäcker M, Schikorra M, Kleiner M (2007) Verbundstrangpressen. In: Kleiner M, Baier H, Fleischer J, Löhe D, Weinert K, Zäh M, Schikorra M (eds) Integration von Umformen, Trennen und Fügen für die flexible Fertigung von leichten Tragwerkstrukturen: Ergebnisbericht der Phase I. Düsseldorf: VDI Verlag 2007, pp 39–67 (Fortschritt-Berichte 661)

Schikorra M (2007) Modellierung und simulationsgestützte Analyse des Verbundstrangpressens. Dissertation, Universität Dortmund (2006). Shaker Verlag, Aachen (Institute of forming technology and lightweight construction)

Weidenmann KA, Schulze V, Löhe D, Fleck C (2005) Analysis of the microstructure and the residual stress state of aluminium extrusions reinforced with ropes. Materialwissenschaft und Werkstofftechnik, 36/7, pp 307–312

Schomäcker M (2007) Verbundstrangpressen von Aluminiumprofilen mit endlosen metallischen Verstärkungselementen. Dissertation, Universität Dortmund (2006). Shaker Verlag, Aachen (Institute of forming technology and lightweight construction)

Radaj D (1992) Heat effects of welding—temperature field, residual stresses. Distortion, Springer, Berlin

Goldak JA, Akhlaghi M (2005) Computational welding mechanics. Springer, New York

Hannon AC (2004) Neutron diffraction, instrumentation. Encyclopedia of spectroscopy and spectrometry, pp 1479–1492

Dalle Donne C, Lima E, Wegener J, Pyzalla A, Buslaps T (2001) Investigations on residual stresses in friction stir welds. In: TWI Ltd (ed) Proceedings of the 3rd international symposium on friction stir welding. Kobe, 27th–28th September 2001

Acknowledgments

This paper is based on investigations of the Transregional Collaborative Research Centre TR 10, which is kindly supported by the German Research Foundation (DFG). The neutron measurement took place at the research reactor FRM II of the Technische Universität München. The support of Dr. Michael Hofmann is acknowledged by the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaeh, M.F., Tekkaya, A.E., Langhorst, M. et al. Experimental and numerical investigation of the process chain from composite extrusion to friction stir welding regarding the residual stresses in composite extruded profiles. Prod. Eng. Res. Devel. 3, 353 (2009). https://doi.org/10.1007/s11740-009-0180-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11740-009-0180-2