Abstract

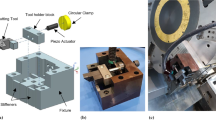

During straight turning of workpieces with non-cylindrical geometry or during milling operations on workpieces with hard surfaces such as the scale layer on cast iron the cutting edge has to withstand high recurrent impact loads. These loads can destroy the cutting edge rather spontaneously than by continuous wear. Commonly used criterions such as a flank or crater wear are not suitable. As part of the research presented in this paper mechanical system properties such as resilience and damping are varied and the influence on tool life is presented. Variation was done passively by changing the material of a shim which was positioned directly under the cutting insert and actively by using a piezo actuator to change the pressure of an oil reservoir close to the cutting insert. The results of this research confirm the potential advantages of a properly adjusted resilience close to the cutting edge. However, a single set of optimal properties for different machining operations or workpiece/tool combinations cannot be derived.

Similar content being viewed by others

References

Schaupp J (1996) Zusammenhang zwischen Antriebsdynamik und Zerspanprozess. In: Karlsruher Kolloquium—Fräsen, Tagungsband März 1996. S. pp 85–103

Weiß H (1983) Fräsen mit Schneidkeramik. wbk Dissertation, Karlsruhe

König W, Klocke F (2002) Fertigungsverfahren Drehen, Fräsen, Bohren. Springer, Berlin

Schaupp J (1997) Wechselwirkung zwischen Maschinen- und Hauptspindelantriebsdynamik und dem Zerspanprozess beim Fräsen. wbk Dissertation, Karlsruhe

VDI 3342 (1999) Programme and fixture for testing the behaviour of carbide cutting tools during breakdown. VDI-Gesellschaft Produktionstechnik

Will D, Gebhardt N, Ströhl H (2007) Hydraulik. Springer, Berlin

Acknowledgments

The authors wish to thank the German Research Foundation (DFG) for support and funding of the project “Standzeitsteigerung bei der Zerspanung durch Nachgiebigkeitsvariation beim Schneideneintrittstoß”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fleischer, J., Becke, C. & Pabst, R. Improving tool life by varying resilience and damping properties in close proximity of the cutting edge. Prod. Eng. Res. Devel. 2, 357–364 (2008). https://doi.org/10.1007/s11740-008-0126-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0126-0