Abstract

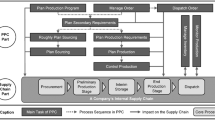

Despite spending considerable effort on the design and operation of production planning and control systems, manufacturing companies experience logistic performance deficits. Frequently, these are due to inconsistencies between the logistic objectives the companies set themselves and the planning and control actions they take to achieve the objectives. Analytical models of logistic processes are applied to obtain a better understanding of the process behavior. Models of this type often do not succeed in clearly establishing the relationships between the planning and control actions the processes can take and the logistic performance measures. The paper presents qualitative influence models that identify these interdependencies within individual logistic processes and across process boundaries. Coupled with a qualitative evaluation of the effects of the planning and control measures on the logistic performance of the processes, the models facilitate objective-oriented logistic performance management.

Similar content being viewed by others

References

Deloitte research: global report—vision in manufacturing. Deloitte Research, New York (1998)

Maurer A, Stark WA (2001) Steering carmaking into the 21st century: from today’s best practices to the transformed plants of 2020. Boston Consulting Group, Boston

Performance Measurement Group (2002) Achieving delivery performance: linking strategy, capabilities and results. Signals Perform 3(4):1–5

Wiendahl H-H, von Cieminski G, Wiendahl H-P (2005) Stumbling blocks of PPC: towards the holistic configuration of PPC systems. Prod Plann Control 16(7):634–651

Wiendahl H-H (2006) Systematic analysis of PPC system deficiencies—analytical approach and consequences for PPC design. Ann CIRP 55(1):479–482

Buzacott JA, Shanthikumar JG (1993) Stochastic models of manufacturing systems. Prentice-Hall, Englewood Cliffs

Silver EA, Pyke DF, Peterson R et al (1998) Inventory management and production planning and scheduling, 3rd edn. Wiley, New York

Hopp WJ, Spearman ML et al (2000) Factory physics: foundations of manufacturing management, 2nd edn. McGraw-Hill, New York

Nyhuis P, von Cieminski G, Fischer F (2005) Applying simulation and analytical models for logistic performance prediction. Ann CIRP 54(1):417–422

Nyhuis P, Wiendahl H-P et al (2007) Fundamentals of production logistics. Springer, Berlin

von Cieminski G (2008) Einsatz qualitativer Wirkmodelle zur Lenkung der industriellen Unternehmens-logistik. PhD thesis to be submitted to the Leibniz University of Hanover

Supply Chain Council: supply-chain operations reference-model Version 8.0. http://www.supply-chain.org/galleries/default-file/SCOR%2080%20Overview%20Booklet2.pdf. Accessed 8 April 2007

Wiendahl H-P et al (1998) Load-oriented manufacturing control, 2nd edn. Springer, Berlin

Ropohl G (1999) Allgemeine technologie: eine systemtheorie der technik, 2nd edn. Carl Hanser, München

Scholz-Reiter B, Windt K, Freitag M (2004) Autonomous logistic processes—new demands and first approaches. In: Proceedings of 37th CIRP ISMS, Budapest, Hungary, pp 357–362

Lutz S, Lödding H, Wiendahl H-P (2003) Logistics-oriented inventory analysis. Int J Prod Econ 85(2):217–231

Lödding H et al (2005) Verfahren der Fertigungssteuerung: Grundlagen, Beschreibung, Konfiguration. Springer, Berlin

Wiendahl H-P, Fastabend H (1997) Synchronization of logistic processes based on coupled operating curves. In: Proceedings of 29th CIRP ISMS, Osaka, Japan

Wiendahl H-P, Ludwig E, Ullmann W (1994) Monitoring and diagnosis systems: new components of production planning and control—methodologies. Appl Exp Int Trans Oper Res 1(1):95–106

Isermann R et al (2005) Fault diagnosis systems: an introduction from fault detection to fault tolerance. Springer, Berlin

Naim MM, Childerhouse P, Disney SM, Towill DR (2002) A supply chain diagnostic methodology—determining the vector of change. Comput Ind Eng 43:135–157

McKinsey & Company (2002) Supply chain quick diagnostics. Logistik heute 24(7–8):34–35 (diagnostic tool on accompanying CD-ROM)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

von Cieminski, G., Nyhuis, P. Modeling and analyzing logistic inter-dependencies in industrial-enterprise logistics. Prod. Eng. Res. Devel. 1, 407–413 (2007). https://doi.org/10.1007/s11740-007-0068-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0068-y