Abstract

Balance of the groundwater and ecology is crucial for controlled discharge. However, regarding the segments of tunnel boring machines (TBMs) under high water pressure, the stability of the lining structure is often reduced by excessive drain holes required to achieve this balance. The large discharge of pinholes can easily have severe consequences, such as the lowering of the groundwater table, drying of springs, and vegetation wilting. Thus, in this study, according to the fluid-structure coupling theory, a new drainage design for TBM segments was developed by considering a mountain tunnel subject to a high water pressure as a case study. The evolution characteristics, including the external water pressure of the lining, discharge volume of the segment, and groundwater-table drawdown, were investigated via numerical modeling with drain holes and pinholes. The results indicated that the optimal design parameters of drainage segments for the project case were as follows: a circumferential spacing angle and longitudinal number on one side of a single ring of 51° and 2, respectively, for the drain holes and an inclination angle and length of 46.41° and 0.25 times the grouting thickness, respectively, for the pin holes.

Similar content being viewed by others

References

Liu J, Liu D, Song K. Evaluation of the influence caused by tunnel construction on groundwater environment: A case study of tongluoshan tunnel, China. Advances in Materials Science and Engineering, 2015: 149265

Wang G F, Wu Y X, Lu L H, Li G, Shen J S. Investigation of the geological and hydrogeological environment with relation to metro system construction in Jinan, China. Bulletin of Engineering Geology and the Environment, 2019, 78(2): 1005–1024

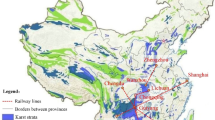

Chen S, Peng H Y, Yang C, Chen B L, Chen L C. Investigation of the impacts of tunnel excavation on karst groundwater and dependent geo-environment using hydrological observation and numerical simulation: A case from karst anticline mountains of southeastern Sichuan Basin, China. Environmental Science and Pollution Research International, 2021, 28(30): 40203–40216

Mossmark F, Annertz K K, Ericsson L O, Norin M. Hydrochemical impact of construction of the western section of the Hallandsås rail tunnel in Sweden. Bulletin of Engineering Geology and the Environment, 2017, 76(2): 751–769

Cheng P, Zhao L H, Luo Z B, Li L, Li Q, Deng X, Peng W Q. Analytical solution for the limiting drainage of a mountain tunnel based on area-well theory. Tunnelling and Underground Space Technology, 2019, 84: 22–30

Yu J Y, Ge S S, Hou L C, Zhang Y T, Liu Y Z. Limit drainage of separated tunnel based on ecological groundwater table: A case study. Advances in Civil Engineering, 2021: 2669924

Gokdemir C, Rubin Y, Li X J, Xu H. A vulnerability assessment method to evaluate the impact of tunnel drainage on terrestrial vegetation under various atmospheric and climatic conditions. Advances in Water Resources, 2021, 147: 103796

Lv Y X, Jiang Y J, Hu W, Cao M, Mao Y. A review of the effects of tunnel excavation on the hydrology, ecology, and environment in karst areas: Current status, challenges, and perspectives. Journal of Hydrology, 2020, 586: 124891

Lee S, Moon J S. Excessive groundwater inflow during TBM tunneling in limestone formation. Tunnelling and Underground Space Technology, 2020, 96: 103217

Aalianvari A, Katibeh H, Sharifzadeh M. Application of fuzzy Delphi AHP method for the estimation and classification of Ghomrud tunnel from groundwater flow hazard. Arabian Journal of Geosciences, 2012, 5(2): 275–284

Gattinoni P, Scesi L. The groundwater rise in the urban area of Milan (Italy) and its interactions with underground structures and infrastructures. Tunnelling and Underground Space Technology, 2017, 62: 103–114

Colombo L, Gattinoni P, Scesi L. Stochastic modelling of groundwater flow for hazard assessment along the underground infrastructures in Milan (northern Italy). Tunnelling and Underground Space Technology, 2018, 79: 110–120

Zhou Z, Zhang J J, Gong C J. Automatic detection method of tunnel lining multi-defects via an enhanced You Only Look Once v4 network. Computer-Aided Civil and Infrastructure Engineering, 2022, 37(6): 762–780

Cheng P, Zhao L H, Li L, Zou J F, Luo W. Limiting drainage criterion for groundwater of mountain tunnel. Journal of Central South University, 2014, 21(12): 4660–4668

Liu B, Wang Y X, Zhao G Z, Yang B, Wang R R, Huang D X, Xiang B. Intelligent decision method for main control parameters of tunnel boring machine based on multi-objective optimization of excavation efficiency and cost. Tunnelling and Underground Space Technology, 2021, 116: 104054

Xu Z H, Wang W Y, Lin P, Nie L C, Wu J, Li Z M. Hard-rock TBM jamming subject to adverse geological conditions: Influencing factor, hazard mode and a case study of Gaoligongshan Tunnel. Tunnelling and Underground Space Technology, 2021, 108: 103683

Shin H S, Youn D J, Chae S E, Shin J H. Effective control of pore water pressures on tunnel linings using pin-hole drain method. Tunnelling and Underground Space Technology, 2009, 24(5): 555–561

Kim D R, Kim H J, Shin J H. Performance evaluation of pin-holed pipe anchor for fractured zone in subsea tunnel. Marine Georesources and Geotechnology, 2017, 35(6): 769–779

Zhang Z J, Zeng C P, Li H, Gao Y, Gong L, Li Y X, Liang H F, Zhang E Z. Optimal design of the seepage control for Xianglushan diversion tunnel under high external water pressure. Geotechnical and Geological Engineering, 2022, 40(9): 4595–4615

Yan Q X, Ma T T, Chen F. Study of influence of water discharge volume on lining external loads for discharge segment lining. Rock and Soil Mechanics, 2011, 32(4): 1108–1112 (in Chinese)

Yan Q X, Cheng X, Zheng J, He C. Analysis on fluid-structure interaction of drainage segment lining under different drainage schemes. Journal of the China Railway Society, 2012, 34(6): 95–100 (in Chinese)

Yan Q X, Zhang M, Cheng X. Study of model test for water pressure distribution character behind drainage segment lining. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(S1): 2617–2623 (in Chinese)

Qi C. Study on mechanical characteristics of segmental lining structure for deep-buried inclined shaft constructed by shield. Dissertation for the Doctoral Degree. Chengdu: Southwest Jiaotong University, 2017 (in Chinese)

Afshani A, Li W, Oka S, Itoh Y, Akagi H. Study of the long-term behavior of segmented tunnels in cohesive soil based on the circumferential joint opening. Tunnelling and Underground Space Technology, 2022, 120: 104210

GB 50164-2011. Chinese Standard for Quality Control of Concrete. Beijing: China Architecture Publishing & Media Co., Ltd., 2011, 9–10

Li P F, Wang F, Long Y Y, Zhao X. Investigation of steady water inflow into a subsea grouted tunnel. Tunnelling and Underground Space Technology, 2018, 80: 92–102

Li L Y, Yang J S, Wang L C, Wang S Y, Fang X H, Xie Y P. Cause analysis and treatment measures of the inverted arch heaving disease of a high-speed railway tunnel under heavy rainfall. Modern Tunnelling Technology, 2021, 58(1): 27–36

Zhao T C, Han T R, Wu G, Gao Y, Lu Y. Effects of grouting in reducing excessive tunnel lining deformation: Field experiment and numerical modelling using material point method. Tunnelling and Underground Space Technology, 2021, 116: 104114

Arnau O, Molins C. Theoretical and numerical analysis of the three-dimensional response of segmental tunnel linings subjected to localized loads. Tunnelling and Underground Space Technology, 2015, 49: 384–399

Wang S C, Jiang X, Bai Y. The influence of hand hole on the ultimate strength and crack pattern of shield tunnel segment joints by scaled model test. Frontiers of Structural and Civil Engineering, 2019, 13(5): 1200–1213

Gong C J, Wang Y Y, Peng Y C, Ding W Q, Lei M F, Da Z, Shi C H. Three-dimensional coupled hydromechanical analysis of localized joint leakage in segmental tunnel linings. Tunnelling and Underground Space Technology, 2022, 130: 104726

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 41972276), the Natural Science Foundation of Fujian Province (No. 2020J06013), and the “Foal Eagle Program” Youth Top-notch Talent Project of Fujian Province (No. 00387088). The financial support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Huang, M., Chen, Z. et al. Drainage design combining drain holes and pinholes for tunnel boring machine segments subject to high water pressure. Front. Struct. Civ. Eng. 17, 1723–1738 (2023). https://doi.org/10.1007/s11709-023-0948-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-023-0948-z