Abstract

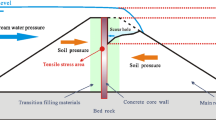

The stress state of the built-in corridor in core rock-fill dam on thick overburden is extremely complex, which may produce cracking and damage. The purpose of this paper was to investigate the effect of thick overburden on the stress and deformation of the built-in corridor in a rock-fill dam, and ascertain the damage causes of the corridor. The rationality of the analysis method for corridor with similar structure is another focus. The approach is based on finite-element method and the calculation result accuracy is verified by the field monitoring data. The improved analysis method for corridors with similar structure is proposed by comparing various corridor load calculation methods and concrete constitutive models. Results demonstrate that the damage causes of the corridor are the deformability difference between the overburden and concrete and the special structural form. And the calculation model considering dam construction process, contact between concrete and surrounding soil, and concrete damage plasticity can reasonably reflect the mechanical behavior of the corridor. The research conclusions may have a reference significance for the analysis of tunnels similar to built-in corridors.

Similar content being viewed by others

References

Fisk M. Late Quaternary Deltaic deposits of the Mississippi River (local sedimentation and basin tectonics). Geological Society of America, 1955, 62: 279–302

Liu S H, Wang L J, Wang Z J, Bauer E. Numerical stress-deformation analysis of cut-off wall in clay-core rockfill dam on thick overburden. Water Science and Engineering, 2016, 9(3): 219–226

Ma H, Sui W, Ni J. Environmentally sustainable mining: A case study on surface subsidence control of grouting into overburden. Environmental Earth Sciences, 2019, 78(10): 320

Akhenak A, Duviella E, Bako L, Lecoeuche S. Online fault diagnosis using recursive subspace identification: Application to a dam-gallery open channel system. Control Engineering Practice, 2013, 21(6): 797–806

Mirzabozorg H, Ghaemian M, Roohezamin A. The reason of cracking in bottom gallery of SefidRud Buttress Dam and earthquake and post earthquake performance. Structural Monitoring and Maintenance, 2019, 6(2): 103–124

Türkmen S. Water leakage from the power tunnel of Gezende Dam, southern Turkey: A case study. Environmental Earth Sciences, 2010, 61(2): 419–427

Zhang W G, Liu F, Jiao L C. Analyze and evaluation of deformation of structural joint and leakage at Qiaoqi Dam’s foundation gallery. Modern Rockfill Dams, 2009: 767–773

Goel R K, Jethwa J L, Paithankar A G. Tunnelling through the young Himalayas—A case history of the Maneri-Uttarkashi power tunnel. Engineering Geology, 1995, 39(1–2): 31–44

Jeong S S, Han Y C, Kim Y M, Kim D H. Evaluation of the NATM tunnel load on concrete lining using the ground lining interaction model. KSCE Journal of Civil Engineering, 2014, 18(2): 672–682

Jiang Y, Yoneda H, Tanabashi Y. Theoretical estimation of loosening pressure on tunnels in soft rocks. Tunnelling and Underground Space Technology, 2001, 16(2): 99–105

Kim H J. Estimation for tunnel lining loads. Dissertation for the Doctoral Degree. Edmonton: University of Alberta, 1997

Zheng Y, Qiu C. On the Limitations of Protodyakonov’s Pressure Arch Theory. Modern Tunnelling Technology, 2016, 53(2): 1–8

Zou H, Wei X, Sun Y. Study on difference of Chinese and foreign structural analysis method of tunnel lining. Yangtze River, 2016, 47(6): 48–64 (in Chinese)

SL279-2002. Water Conservancy Industry Standard of the People’s Republic of China. Specification for Design of Hydraulic Tunnel. Beijing: China Water Power Press, 2003 (in Chinese)

TB10003-2016. Industrial Standards of the People’s Republic of China. Code for Design of Railway Tunnel. Beijing: China Railway Press, 2017 (in Chinese)

GB 50010-2010. Code for Design of Concrete Structures. Beijing: China Architecture & Building Press, 2015 (in Chinese)

Häussler-Combe U, Hartig J. Formulation and numerical implementation of a constitutive law for concrete with strain-based damage and plasticity. International Journal of Non-linear Mechanics, 2008, 43(5): 399–415

Chiaia B, Fantilli A P, Vallini P. Combining fiber-reinforced concrete with traditional reinforcement in tunnel linings. Engineering Structures, 2009, 31(7): 1600–1606

Lee S Y, Lee S H O, Shin D I K, Son Y K, Han C S. Development of an inspection system for cracks in a concrete tunnel lining. Canadian Journal of Civil Engineering, 2007, 34(8): 966–975

Wang T T. Characterizing crack patterns on tunnel linings associated with shear deformation induced by instability of neighboring slopes. Engineering Geology, 2010, 115(1–2): 80–95

Nehdi M L, Abbas S. Exploratory study of ultra-high performance fiber reinforced concrete tunnel lining segments with varying steel fiber lengths and dosages. Engineering Structures, 2015, 101: 733–742

Yu T, Zhu A, Chen Y. Efficient crack detection method for tunnel lining surface cracks based on infrared images. Journal of Computing in Civil Engineering, 2017, 31(3): 04016067

Manuello A, Niccolini G, Carpinteri A. AE monitoring of a concrete arch road tunnel: Damage evolution and localization. Engineering Fracture Mechanics, 2019, 210: 279–287

Mikkelsen L P, Klitgaard S J, Niordson C F, Sørensen B F. Tunneling cracks in arbitrary oriented off-axis lamina. International Journal of Fracture, 2020, 226(2): 161–179

Gu J, Chen P. A failure criterion for isotropic materials based on Mohr’s failure plane theory. Mechanics Research Communications, 2018, 87: 1–6

Duncan J M, Chang C Y. Nonlinear analysis of stress and strain in soils. Journal of the Soil Mechanics and Foundations Division, 1970, 96(5): 1629–1653

Goodman R E, Taylor R L, Brekke T L. A model for the mechanics of jointed rock. Journal of the Soil Mechanics and Foundations Division, 1968, 94(3): 637–659

Huang D, Tang A, Wang Z. Analysis of pipe-soil interactions using goodman contact element under seismic action. Soil Dynamics and Earthquake Engineering, 2020, 139(5): 106290

Pedersen R R, Simone A, Sluys L J. An analysis of dynamic fracture in concrete with a continuum visco-elastic visco-plastic damage model. Engineering Fracture Mechanics, 2008, 75(13): 3782–3805

Yu T, Teng J G, Wong Y L, Dong S L. Finite element modeling of confined concrete-II: Plastic-damage model. Steel Construction, 2010, 32(3): 680–691

Abu Al-Rub R, Kim S M. Computational applications of a coupled plasticity-damage constitutive model for simulating plain concrete fracture. Engineering Fracture Mechanics, 2010, 77(10): 1577–1603

Jukic M, Brank B, Ibrahimbegovic A. Failure analysis of reinforced concrete frames by beam finite element that combines damage, plasticity and embedded discontinuity. Engineering Structures, 2014: 75: 507–527

Yan J B, Qian X, Liew J, Zong L. Damage plasticity based numerical analysis on steel—concrete—steel sandwich shells used in the Arctic offshore structure. Engineering Structures, 2016, 117: 542–559

Othman H, Marzouk H. Applicability of damage plasticity constitutive model for ultra-high performance fibre-reinforced concrete under impact loads. International Journal of Impact Engineering, 2018, 114: 20–31

Kenawy M, Kunnath S, Kolwankar S, Kanvinde A. Concrete uniaxial nonlocal damage-plasticity model for simulating post-peak response of reinforced concrete beam-columns under cyclic loading. Journal of structural engineering, 2020, 146(5): 04020052

Seok S, Haikal G, Ramirez J A, Lowes L N, Lim J. Finite element simulation of bond-zone behavior of pullout test of reinforcement embedded in concrete using concrete damage-plasticity model 2 (CDPM2). Engineering Structures, 2020, 221: 110984

Lj A, Mao A, Jian J B, Au A. Modelling concrete slabs subjected to fires using nonlinear layered shell elements and concrete damage-plasticity material. Engineering Structures, 2021, 234: 111977

Nechnech W, Meftah F, Reynouard J M. An elasto-plastic damage model for plain concrete subjected to high temperatures. Engineering Structures, 2002, 24(5): 597–611

Krätzig W B, Pölling R. An elasto-plastic damage model for reinforced concrete with minimum number of material parameters. Computers & Structures, 2004, 82(15–16): 1201–1215

Feng DC, Wu G, Sun Z Y, Xu J G. A flexure-shear Timoshenko fiber beam element based on softened damage-plasticity model. Engineering Structures, 2017, 140: 483–497

Yu T, Teng J G, Wong Y L, Dong S L. Finite element modeling of confined concrete-I: Drucker-Prager type plasticity model. Engineering Structures, 2010, 32(3): 665–679

Jiang J F, Wu Y F. Identification of material parameters for Drucker—Prager plasticity model for FRP confined circular concrete columns. International Journal of Solids and Structures, 2012, 49(3–4): 445–456

Lubliner J, Oliver J, Oller S, Onate E. A plastic-damage model for concrete. International Journal of Solids and Structures, 1989, 25(3): 299–326

Genikomsou A S, Polak M A. Finite element analysis of punching shear of concrete slabs using damaged plasticity model in ABAQUS. Engineering Structures, 2015, 98: 38–48

Acknowledgements

This work reported here was supported by the National Natural Science Foundation of China/Yalong River Joint Fund Project (Grant No. U1765205) and Jiangsu Colleges and Universities Advantageous Discipline Construction Project (Water Conservancy Project) (No. YS11001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, J., Shen, Z. & Huang, Z. Analysis on damage causes of built-in corridor in core rock-fill dam on thick overburden: A case study. Front. Struct. Civ. Eng. 16, 762–780 (2022). https://doi.org/10.1007/s11709-022-0847-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0847-8