Abstract

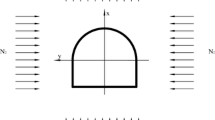

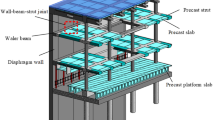

In order to study the bearing performance of a new type of prefabricated subway station structure (PSSS), firstly, a three-dimensional finite element model of the PSSS was established to study the nonlinear mechanics and deformation performance. Secondly, the bearing mechanism of a PSSS was investigated in detail. Finally, the development law of damages to a thin-walled prefabricated component and the failure evolution mechanism of a PSSS were discussed. The results showed that this new type of the PSSS had good bearing capacity. The top arch structure was a three-hinged arch bearing system, and the enclosure structure and the substructure were respectively used as the horizontal and vertical support systems of the three-hinged arch structure to ensure the integrity and stability of the overall structure. Moreover, the tongue-and-groove joints could effectively transmit the internal force between the components and keep the components deformed in harmony. The rigidity degradation of the PSSS caused by the accumulation of damages to the spandrel, hance, arch foot, and enclosure structure was the main reason of its loss of bearing capacity. The existing thin-walled components design had significant advantages in weight reduction, concrete temperature control, components hoisting, transportation and assembly construction, which achieved a good balance between safety, usability and economy.

Similar content being viewed by others

References

Badir Y F, Kadir M R A, Hashim A H. Industrialized building systems construction in Malaysia. Journal of Architectural Engineering, 2002, 8(1): 19–23

Zhao C, Zhang Z, Wang J, Wang B. Numerical and theoretical analysis on the mechanical properties of improved CP-GFRP splice sleeve. Thin-walled Structures, 2019, 137: 487–501

Wang Z, Shen H, Zuo J. Risks in prefabricated buildings in China: Importance-performance analysis approach. Sustainability, 2019, 11(12): 3450

Liu G, Gu T, Xu P, Hong J, Shrestha A, Martek I. A production line-based carbon emission assessment model for prefabricated components in China. Journal of Cleaner Production, 2019, 209: 30–39

Frosch R J, Li W, Jirsa J O, Kreger M E. Retrofit of non-ductile moment-resisting frames using precast infill wall panels. Earthquake Spectra, 1996, 12(4): 741–760

Kesner K, Billington S L. Investigation of infill panels made from engineered cementitious composites for seismic strengthening and retrofit. Journal of Structural Engineering, 2005, 131(11): 1712–1720

Boyd N, Khalfan M M A, Maqsood T. Off-site construction of apartment buildings. Journal of Architectural Engineering, 2013, 19(1): 51–57

Wan Omar W M S, Doh J H, Panuwatwanich K, Miller D. Assessment of the embodied carbon in precast concrete wall panels using a hybrid life cycle assessment approach in Malaysia. Sustainable Cities and Society, 2014, 10: 101–111

Steinhardt D A, Manley K. Adoption of prefabricated housing—The role of country context. Sustainable Cities and Society, 2016, 22: 126–135

Kasperzyk C, Kim M K, Brilakis I. Automated re-prefabrication system for buildings using robotics. Automation in Construction, 2017, 83: 184–195

Lacey A W, Chen W, Hao H, Bi K. Structural response of modular buildings—An overview. Journal of Building Engineering, 2018, 16: 45–56

Ferdous W, Bai Y, Ngo T D, Manalo A, Mendis P. New advancements, challenges and opportunities of multi-storey modular buildings—A state-of-the-art review. Engineering Structures, 2019, 183: 883–893

Tao L, Ding P, Lin H, Wang H, Kou W, Shi C, Li S, Wu S. Three-dimensional seismic performance analysis of large and complex underground pipe trench structure. Soil Dynamics and Earthquake Engineering, 2021, 150: 106904

Deng Z, Liang N, Liu X, de la Fuente A, Lin P, Peng H. Analysis and application of friction calculation model for long-distance rock pipe jacking engineering. Tunnelling and Underground Space Technology, 2021, 115: 104063

Su H, Liu W, Liu F. Preliminary ideas of the metro station constructed by shield tunneling method combined with prefabricated method. Applied Mechanics and Materials, 2014, 580–583: 1013–1018

Yang X, Lin F. Prefabrication technology for underground metro station structure. Tunnelling and Underground Space Technology, 2021, 108: 103717

Freas G C, Shoemaker M J, Ervin D. Precast prestressed underground fuel storage tanks in Adak, Alaska. PCI Journal, 1985, 30(4): 52–63

Yurkevich P. Developments in segmental concrete linings for subway tunnels in Belarus. Tunnelling and Underground Space Technology, 1995, 10(3): 353–365

Fukayama K, Shinagawa K. Design-construction of circular roof for underground reservoir using precast concrete beams. PCI Journal, 1998, 43(5): 46–54

Scott J, Nelson C, Middleton L, Reneson D, Stehler D. Curved precast concrete panels carve out underground library at University of Minnesota. PCI Journal, 2000, 45(1): 40–49

Chen J, Mo H. Mechanical behavior of segment rebar of shield tunnel in construction stage. Journal of Zhejiang University-Science A, 2008, 9(7): 888–899

He C, Wang B. Research progress and development trends of highway tunnels in China. Journal of Modern Transportation, 2013, 21(4): 209–223

Zhu H, Huang B, Li X, Hashimoto T. Unified model for internal force and deformation of shield segment joints and experimental analysis. Chinese Journal of Geotechnical Engineering, 2014, 36: 2153–2160 (in Chinese)

Zhuang X, Zhu H, Augarde C. An improved meshless Shepard and least squares method possessing the delta property and requiring no singular weight function. Computational Mechanics, 2014, 53(2): 343–357

Yang X, Han Y. Closed cavity thin-wall components design for prefabricated underground subway structures. In: Geo-risk Conference, 2017: Reliability-Based Design and Code Developments. 194–205

Yang X, Huang M, Lin F. Experimental study on flexural bearing capability of short grouted single mortise-tenon joints in prefabricated metro station structure. China Civil Engineering Journal, 2020, 53: 57–64 (in Chinese)

Yang X, Lin F, Huang M. Research on flexural bearing capability of long grouted single mortise-tenon joints for prefabricated metro station structures. China Civil Engineering Journal, 2020, 53: 111–118+128 (in Chinese)

Ding P, Tao L, Yang X, Zhao J, Shi C. Three-dimensional dynamic response analysis of a single-ring structure in a prefabricated subway station. Sustainable Cities and Society, 2019, 45: 271–286

Ding P, Tao L, Yang X, Zhao J, Shi C, An S. Force transfer and deformation mechanism of single ring structure of prefabricated subway station. Journal of Southwest Jiaotong University, 2020, 55: 1076–1084+1110 (in Chinese)

Ding P, Tao L J, Shi C, Wu X W, Wu S, Li S C. Study on horizontal and vertical seismic response of single-arch and large-span prefabricated subway station. In: 14th International Congress on Rock Mechanics and Rock Engineering. Foz do Iguaçu: ISRM, 2020: 772–2779

Tao L, Ding P, Shi C, Wu X, Wu S, Li S. Shaking table test on seismic response characteristics of prefabricated subway station structure. Tunnelling and Underground Space Technology, 2019, 91: 102994

Tao L, Ding P, Yang X, Lin P, Shi C, Bao Y, Wei P, Zhao J. Comparative study of the seismic performance of prefabricated and cast-in-place subway station structures by shaking table test. Tunnelling and Underground Space Technology, 2020, 105: 103583

Li Z, Li S, Su H. Study on the bending stiffness for double tenon-groove joints of metro station constructed by using prefabricated structure. China Civil Engineering Journal, 2017, 50: 14–18 (in Chinese)

Li Z, Su H, Lu S, Wang C, Xu X. Experimental study on flexural mechanical properties of the double tenon groove joints of prefabricated subway station. China Civil Engineering Journal, 2017, 50: 28–32 (in Chinese)

Li Z, Li K, Lu S, Su H, Wang C. Experimental study on stress evolution rule of double tenon-groove joints for prefabricated metro station structure. China Railway Science, 2018, 39: 15–21 (in Chinese)

Du X, Liu H, Lu D, Xu C, Luo F, Li S. Study on seismic performance of sidewall joints in assembled monolithic subway station. China Civil Engineering Journal, 2017, 50: 38–47 (in Chinese)

Du X, Liu H, Xu C, Jin L, Luo F, Li S. Experimental study on seismic performance of precast column in assembled monolithic subway station under different axial compression ratio. Journal of Building Structures, 2018, 39: 11–19 (in Chinese)

Liu H, Yan Q, Du X. Seismic performance comparison between precast beam joints and cast-in-place beam joints. Advances in Structural Engineering, 2017, 20(9): 1299–1314

Liu H, Han Q, Bai Y, Xu C, Du X. Connection performance of restrained deformed grouted sleeve splice. Advances in Structural Engineering, 2018, 21(3): 488–499

Lu L, Han S, Chen Z, Wang G, Wang Y, Zhao K. Study on bending performance of prefabricated square pile with socket and spigot joint. Journal of Building Structures, 2018, 39: 153–161 (in Chinese)

Jin J, Jia J, Huang W. Structural design and construction key technology of precast arch roof plate in subway station. Building Construction, 2020, 42: 1513–1515 (in Chinese)

Chu M, Liu J, Hou J, Qiu G, Liu M, Wang G. Experimental study on mechanical behaviors of concrete shear wall with precast two-way hollow slabs. Journal of Building Structures, 2017, 38: 32–40 (in Chinese)

Xiong C, Chu M, Liu J, Sun Z. Shear behavior of precast concrete wall structure based on two-way hollow-core precast panels. Engineering Structures, 2018, 176: 74–89

Gu Q, Dong G, Ke Y, Tian S, Wen S, Tan Y, Gao X. Seismic behavior of precast double-face superposed shear walls with horizontal joints and lap spliced vertical reinforcement. Structural Concrete, 2020, 21(5): 1973–1988

Lee D H, Park M K, Oh J Y, Kim K S, Im J H, Seo S Y. Webshear capacity of prestressed hollow-core slab unit with consideration on the minimum shear reinforcement requirement. Computers and Concrete, 2014, 14(3): 211–231

Park M K, Lee D H, Han S J, Kim K S. Web-shear capacity of thick precast prestressed hollow-core slab units produced by extrusion method. International Journal of Concrete Structures and Materials, 2019, 13(1): 7

Nguyen T N H, Tan K H, Kanda T. Investigations on web-shear behavior of deep precast, prestressed concrete hollow core slabs. Engineering Structures, 2019, 183: 579–593

El-Remaily A, Tadros M K, Yamane T, Krause G. Transverse design of adjacent precast prestressed concrete box girder bridges. PCI Journal, 1996, 41(4): 96–107

Attanayake U, Aktan H. First-generation ABC system, evolving design, and half a century of performance: Michigan side-by-side box-beam bridges. Journal of Performance of Constructed Facilities, 2015, 29(3): 04014090

Barbieri D M, Chen Y, Mazzarolo E, Briseghella B, Tarantino A M. Longitudinal joint performance of a concrete hollow core slab bridge. Transportation Research Record: Journal of the Transportation Research Board, 2018, 2672(41): 196–206

Ou Y, Chiewanichakorn M, Aref A J, Lee G C. Seismic performance of segmental precast unbonded posttensioned concrete bridge columns. Journal of Structural Engineering, 2007, 133(11): 1636–1647

Kim D H, Moon D Y, Kim M K, Zi G, Roh H. Experimental test and seismic performance of partial precast concrete segmental bridge column with cast-in-place base. Engineering Structures, 2015, 100: 178–188

Zhu L, Zhang B, Guo Y. Cost analysis and countermeasure research of prefabricated stairs on site. Build Structure, 2019, 49: 539–544 (in Chinese)

Lubliner J, Oliver J, Oller S, Oñate E. A plastic-damage model for concrete. International Journal of Solids and Structures, 1989, 25(3): 299–326

Lee J, Fenves G L. Plastic-damage model for cyclic loading of concrete structures. Journal of Engineering Mechanics, 1998, 124(8): 892–900

GB 50010-2010. Code for Design of Concrete Structures. Beijing: China Architecture & Building Press, 2010 (in Chinese)

Abaqus. Version 6.14. Documentation. Providence, RI: Dassault Systèmes, 2015

Yang X, Shi Z, Lin F. Influence of geometrical parameters on performance of grouted mortise and tenon joints for application in prefabricated underground structures. Advances in Civil Engineering, 2019, 2019: 1–14

GB 50911-2013. Code for monitoring measurement of urban rail transit engineering. Beijing: China Architecture & Building Press, 2013 (in Chinese)

Acknowledgements

The authors gratefully acknowledgement the financial support provided by the National Key R&D Program of China (Nos. 2017YFC0805403 and 2019YFC1509704), and the National Natural Science Foundation of China (Grant Nos. 41877218 and 42072308).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, L., Shi, C., Ding, P. et al. A study on bearing characteristic and failure mechanism of thin-walled structure of a prefabricated subway station. Front. Struct. Civ. Eng. 16, 359–377 (2022). https://doi.org/10.1007/s11709-022-0816-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0816-2