Abstract

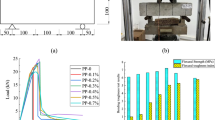

The understanding of compressive and tensile behaviors of polypropylene fiber-reinforced cemented paste backfill (FR-CPB) play crucial roles in the successful implementation of reinforcement technique in underground mine backfilling operations. However, very limited studies have been performed to gain insight into the evolution of compressive and tensile behaviors and associated mechanical properties of FR-CPB under various curing temperatures from early to advanced ages. Thus, this study aims to investigate the time (7, 28, and 90 d)- and temperature (20°C, 35°C, and 45°C)-dependence of constitutive behavior and mechanical properties of FR-CPB. The obtained results show that pre- and post-failure behaviors of FR-CPB demonstrate strongly curing temperature-dependence from early to advanced ages. Moreover, the pseudo-hardening behavior is sensitive to curing temperature, especially at early ages. Furthermore, the mechanical properties including elastic modulus, material stiffness, strengths, brittleness, cohesion, and internal friction angle of FR-CPB show increasing trends with curing temperature as curing time elapses. Additionally, a predictive model is developed to capture the strong correlation between compressive and tensile strength of FR-CPB. The findings of this study will contribute to the successful implementation of FR-CPB technology.

Similar content being viewed by others

References

Lu G, Fall M, Cui L. A multiphysics-viscoplastic cap model for simulating blast response of cemented tailings backfill. Journal of Rock Mechanics and Geotechnical Engineering, 2017, 9(3): 551–564

Chen Q S, Sun S Y, Liu Y K, Qi C C, Zhou H B, Zhang Q L. Experimental and numerical study on immobilization and leaching characteristics of fluoride from phosphogypsum based cemented paste backfill. International Journal of Minerals, Metallurgy and Materials, 2021 (in press)

Qian Q, Lin P. Safety risk management of underground engineering in China: Progress, challenges and strategies. Journal of Rock Mechanics and Geotechnical Engineering, 2016, 8(4): 423–442

Pourmalek A, Shariatipour S M. Dependence on temperature and salinity gradients and the injection rate of CO2 storage in saline aquifers with an angular unconformity. Journal of Porous Media, 2019, 22(8): 1065–1078

Cui L, Fall M. Mechanical and thermal properties of cemented tailings materials at early ages: Influence of initial temperature, curing stress and drainage conditions. Construction & Building Materials, 2016, 125: 553–563

Bazhuni M F, Kamali M, Ghahremaninezhad A. An investigation into the properties of ternary and binary cement pastes containing glass powder. Frontiers of Structural and Civil Engineering, 2019, 13(3): 741–750

Walske M L, McWilliam H, Doherty J, Fourie A. Influence of curing temperature and stress conditions on mechanical properties of cementing paste backfill. Canadian Geotechnical Journal, 2015, 53(1): 148–161

Fall M, Célestin J, Pokharel M, Touré M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Engineering Geology, 2010, 114(3–4): 397–413

Fang K, Fall M. Effects of curing temperature on shear behaviour of cemented paste backfill-rock interface. International Journal of Rock Mechanics and Mining Sciences, 2018, 112: 184–192

Chen X, Shi X, Zhou J, Yu Z. Influence of polypropylene fiber reinforcement on tensile behavior and failure mode of tailings cemented paste backfill. IEEE Access, 2019, 7: 69015–69026

Libos I L S, Cui L. Effects of curing time, cement content, and saturation state on mode-I fracture toughness of cemented paste backfill. Engineering Fracture Mechanics, 2020, 235: 107174

Kumar D, Singh U K, Singh G S P. Laboratory characterization of cemented rock fill for underhand cut and fill method of mining. Journal of the Institution of Engineers (India): Series D, 2016, 97(2): 193–203

Yi X, Ma G, Fourie A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotextiles and Geomembranes, 2015, 43(3): 207–215

Chakilam S, Cui L. Effect of polypropylene fiber content and fiber length on the saturated hydraulic conductivity of hydrating cemented paste backfill. Construction & Building Materials, 2020, 262: 120854

Cao S, Zheng D, Yilmaz E, Yin Z, Xue G, Yang F. Strength development and microstructure characteristics of artificial concrete pillar considering fiber type and content effects. Construction & Building Materials, 2020, 256: 119408

Xu W, Li Q, Zhang Y. Influence of temperature on compressive strength, microstructure properties and failure pattern of fiber-reinforced cemented tailings backfill. Construction & Building Materials, 2019, 222: 776–785

Chen X, Shi X, Zhou J, Chen Q, Li E, Du X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Construction & Building Materials, 2018, 190: 211–221

Cui L, Fall M. Multiphysics modeling and simulation of strength development and distribution in cemented tailings backfill structures. International Journal of Concrete Structures and Materials, 2018, 12(1): 1–22

Pokharel M, Fall M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill. Cement and Concrete Composites, 2013, 38: 21–28

Wang Y, Cao Y, Cui L, Si Z, Wang H. Effect of external sulfate attack on the mechanical behavior of cemented paste backfill. Construction & Building Materials, 2020, 263: 120968

Tariq A, Yanful E K. A review of binders used in cemented paste tailings for underground and surface disposal practices. Journal of Environmental Management, 2013, 131: 138–149

Koohestani B, Belem T, Koubaa A, Bussière B. Experimental investigation into the compressive strength development of cemented paste backfill containing Nano-silica. Cement and Concrete Composites, 2016, 72: 180–189

Wu A, Wang Y, Wang H, Yin S, Miao X. Coupled effects of cement type and water quality on the properties of cemented paste backfill. International Journal of Mineral Processing, 2015, 143: 65–71

Cao S, Xue G, Yilmaz E. Flexural behavior of fiber reinforced cemented tailings backfill under three-point bending. IEEE Access, 2019, 7: 139317–139328

Cao S, Yilmaz E, Song W. Fiber type effect on strength, toughness and microstructure of early age cemented tailings backfill. Construction & Building Materials, 2019, 223: 44–54

Xu W, Chen W, Tian M, Guo L. Effect of temperature on time-dependent rheological and compressive strength of fresh cemented paste backfill containing flocculants. Construction & Building Materials, 2021, 267: 121038

Xu W, Zhang Y, Zuo X, Hong M. Time-dependent rheological and mechanical properties of silica fume modified cemented tailings backfill in low temperature environment. Cement and Concrete Composites, 2020, 114: 103804

ASTM C192/C192M-18. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. West Conshohocken, PA: ASTM International, 2018

Chen Q, Zhang Q, Qi C, Fourie A, Xiao C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. Journal of Cleaner Production, 2018, 186: 418–429

Cui L, Fall M. An evolutive elasto-plastic model for cemented paste backfill. Computers and Geotechnics, 2016, 71: 19–29

ASTM C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. West Conshohocken, PA: ASTM International, 2018

ASTM D3967-16. Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. West Conshohocken, PA: ASTM International, 2016

Sun B, Wu H, Song W, Li Z, Yu J. Hydration, microstructure and autogenous shrinkage behaviors of cement mortars by addition of superabsorbent polymers. Frontiers of Structural and Civil Engineering, 2020, 14(5): 1274–1284

Ghirian A, Fall M. Coupled behavior of cemented paste backfill at early ages. Geotechnical and Geological Engineering, 2015, 33(5): 1141–1166

Haruna S, Fall M. Strength development of cemented tailings materials containing polycarboxylate ether-based superplasticizer: Experimental results on the effect of time and temperature. Canadian Journal of Civil Engineering, 2021, 48(4): 429–442

Fall M, Belem T, Samb S, Benzaazoua M. Experimental characterization of the stress-strain behaviour of cemented paste backfill in compression. Journal of Materials Science, 2007, 42(11): 3914–3922

Martin B E, Chen W, Song B, Akers S A. Moisture effects on the high strain-rate behavior of sand. Mechanics of Materials, 2009, 41(6): 786–798

Boughanem S, Jesson D, Mulheron M, Smith P, Eddie C, Psomas S, Rimes M. Tensile characterisation of thick sections of Engineered Cement Composite (ECC) materials. Journal of Materials Science, 2015, 50(2): 882–897

Libos I L S, Cui L. Mechanical properties and behavior of early-age fiber-reinforced cemented paste backfill. In: Proceedings of the 5th International Conference on Civil Structural and Transportation Engineering, Virtual Conference. Avestia, 2020, 1–6

Cui L, Fall M. Modeling of self-desiccation in a cemented backfill structure. International Journal for Numerical and Analytical Methods in Geomechanics, 2018, 42(3): 558–583

Cui L, Fall M. Numerical simulation of consolidation behavior of large hydrating fill mass. International Journal of Concrete Structures and Materials, 2020, 14(23): 1–16

Wang H S, Tang C S, Gu K, Shi B, Inyang H I. Mechanical behavior of fiber-reinforced, chemically stabilized dredged sludge. Bulletin of Engineering Geology and the Environment, 2020, 79(2): 629–643

Liu L, Liu H, Stuedlein A W, Evans T M, Xiao Y. Strength, stiffness, and microstructure characteristics of biocemented calcareous sand. Canadian Geotechnical Journal, 2019, 56(10): 1502–1513

Gafoor A H M A, Dinkler D. A macroscopic gradient-enhanced damage model for deformation behavior of concrete under cyclic loadings. Archive of Applied Mechanics, 2020, 90(5): 1179–1199

Bekele A, Ryden N, Gudmarsson A, Birgisson B. Effect of cyclic low temperature conditioning on stiffness modulus of asphalt concrete based on non-contact resonance testing method. Construction & Building Materials, 2019, 225: 502–509

Kim J J, Rahman M K, Taha M M R. Examining microstructural composition of hardened cement paste cured under high temperature and pressure using nanoindentation and 29 Si MAS NMR. Applied Nanoscience, 2012, 2(4): 445–456

Kim Y J, Hu J, Lee S J, You B H. Mechanical properties of fiber reinforced lightweight concrete containing surfactant. Advances in Civil Engineering, 2010, 2010: 1–8

Bhaskar P, Mohamed R H. Analytical estimation of elastic properties of polypropylene fiber matrix composite by finite element analysis. Advances in Materials Physics and Chemistry, 2012, 2012: 23–30

Ravichandran N, Krishnapillai S H. Effect of deformation-induced suction in the behavior of unsaturated fine-grained soils using simplified finite-element model. International Journal of Geomechanics, 2013, 13(5): 483–495

Zhou W, Wang H, Wang D, Du Y, Zhang K, Qiao Y. An experimental investigation on the influence of coal brittleness on dust generation. Powder Technology, 2020, 364: 457–466

Coates D, Parsons R. Experimental criteria for classification of rock substances. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1966, 3(3): 181–189

Hajiabdolmajid V, Kaiser P. Brittleness of rock and stability assessment in hard rock tunneling. Tunnelling and Underground Space Technology, 2003, 18(1): 35–48

Rybacki E, Meier T, Dresen G. What controls the mechanical properties of shale rocks?—Part II: Brittleness. Journal of Petroleum Science Engineering, 2016, 144: 39–58

Hucka V, Das B. Brittleness determination of rocks by different methods. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1974, 11(10): 389–392

Altindag R. The evaluation of rock brittleness concept on rotary blast hold drills. Journal of the Southern African Institute of Mining and Metallurgy, 2002, 102(1): 61–66

Ghadakpour M, Choobbasti A J, Kutanaei S S. Investigation of the Kenaf fiber hybrid length on the properties of the cement-treated sandy soil. Transportation Geotechnics, 2020, 22: 100301

Piratheepan J, Gnanendran C, Arulrajah A. Determination of c and φ from IDT and unconfined compression testing and numerical analysis. Journal of Materials in Civil Engineering, 2012, 24(9): 1153–1164

Sivakugan N, Das B, Lovisa J, Patra C. Determination of c and φ of rocks from indirect tensile strength and uniaxial compression tests. International Journal of Geotechnical Engineering, 2014, 8(1): 59–65

Soetens T, Matthys S. Shear-stress transfer across a crack in steel fibre-reinforced concrete. Cement and Concrete Composites, 2017, 82: 1–13

Zanotti C, Randl N. Are concrete-concrete bond tests comparable? Cement and Concrete Composites, 2019, 99: 80–88

Acknowledgements

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) for the financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Libos, I.L.S., Cui, L. Time- and temperature-dependence of compressive and tensile behaviors of polypropylene fiber-reinforced cemented paste backfill. Front. Struct. Civ. Eng. 15, 1025–1037 (2021). https://doi.org/10.1007/s11709-021-0741-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0741-9