Abstract

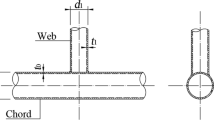

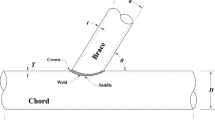

A method for strengthening damaged tubular steel T-joints under axial compression by wrapping them with carbon fiber-reinforced polymer (CFRP) sheets was proposed and evaluated. The influence of the CFRP strengthening on the failure mode and load capacity of T-joints with different degrees of damage was investigated using experiments and finite element analyses. Five T-joints were physically tested: one bare joint to obtain the peak load and corresponding displacement (Δ1m), two reinforced joints to provide a reference, and two pre-damaged then retrofitted joints to serve as the primary research objects. The ratio of the pre-loaded specimen chord displacement to the value of Δ1m was considered to be the degree of damage of the two retrofitted joints, and was set to 0.80 and 1.20. The results demonstrate that the maximum capacity of the retrofitted specimen was increased by 0.83%–15.06% over the corresponding unreinforced specimens. However, the capacity of the retrofitted specimen was 2.51%–22.77% lesser compared with that of the directly reinforced specimens. Next, 111 numerical analysis models (0.63 ⩽ β ⩽ 0.76, 9.70 ⩽ γ ⩽ 16.92) were established to parametrically evaluate the effects of different geometric and strengthening parameters on the load capacity of strengthened tubular T-joints under different degrees of damage. The numerical analysis results revealed that the development of equivalent plastic strain at the selected measuring points was moderated by strengthening with CFRP wrapping, and indicated the optimal CFRP strengthening thickness and wrapping orientation according to tubular T-joint parameters. Finally, reasonable equations for calculating the load capacity of CFRP-strengthened joints were proposed and demonstrated to provide accurate results. The findings of this study can be used to inform improved CFRP strengthening of damaged tubular steel structures.

Similar content being viewed by others

References

Shi G, Zhou W J, Bai Y, Lin C C. Local buckling of 460 MPa high strength steel welded section stub columns under axial compression. Journal of Constructional Steel Research, 2014, 100(Sep): 60–70

Shi G, Wang J J, Bai Y, Shi Y J. Experimental study on seismic behavior of 460 MPa high strength steel box-section columns. Advances in Structural Engineering, 2014, 17(7): 1045–1059

Qu H, Huo J S, Xu C, Fu F. Numerical studies on dynamic behavior of tubular T-joint subjected to impact loading. International Journal of Impact Engineering, 2014, 67(May): 12–26

Zhu L, Song Q M, Bai Y, Wei Y, Ma L M. Capacity of steel CHS T-joints strengthened with external stiffeners under axial compression. Thin-walled Structures, 2017, 113(Apr): 39–46

Li W P, Zhang S G, Huo W Y, Bai Y, Zhu L. Axial compression capacity of steel CHS X-joints strengthened with external stiffeners. International Journal of Impact Engineering, 2014, 67(May): 12–26

Lee M M K, Llewelyn-Parry A. Offshore tubular T-joints reinforced with internal plain annular ring stiffeners. Journal of Structural Engineering, 2004, 130(6): 942–951

Yang J, Shao Y B, Chen C. Static strength of chord reinforced tubular Y-joints under axial loading. Marine Structures, 2012, 29(1): 226–245

Hossein N, Mohammad Ali L Y, Hamid A. Static performance of doubler plate reinforced tubular T/Y-joints subjected to brace tension. Thin-walled Structures, 2016, 108(Nov): 138–152

Choo Y S, Liang J X, van der Vegte G J, Liew J Y R. Static strength of doubler plate reinforced CHS X-joints loaded by in-plane bending. Journal of Constructional Steel Research, 2004, 60(12): 1725–1744

Fung T C, Chan T K, Soh C K. Ultimate capacity of doubler plate-reinforced tubular joints. Journal of Structural Engineering, 1999, 125(8): 891–899

Qu H, Li A L, Huo J S, Liu Y Z. Dynamic performance of collar plate reinforced tubular T-joint with precompression chord. Engineering Structures, 2017, 141: 555–570

Su Y, Li W Y, Wang X Y, Ma T J, Ma L, Dou X M. The sensitivity analysis of microstructure and mechanical properties to welding parameters for linear friction welded rail steel joints. Materials Science and Engineering A, 2019, 764: 138251

CECS (China Association for Engineering Construction Standardization). Technical Specification for Strengthening Concrete Structures with Carbon Fiber Reinforced Polymer Laminate CECS146: 2003(2007). Beijing: China Planning Press, 2007 (in Chinese)

ACI 440R07. Report on Fiber-reinforced Polymer (FRP) Reinforcement for Concrete Structures. ACI, 2007

Lesani M, Bahaari M R, Shokrieh M M. Experimental investigation of FRP-strengthened tubular T-joints under axial compressive loads. Construction & Building Materials, 2014, 53: 243–252

Peng H, Zhang J R, Shang S P, Liu Y, Cai C S. Experimental study of flexural fatigue performance of reinforced concrete beams strengthened with prestressed CFRP plates. Engineering structures, 2016, 127(Nov.15): 62–72

Teng J G, Zhang J W, Smith S T. Interfacial stresses in reinforced concrete beams bonded with a soffit plate: A finite element study. Construction & Building Materials, 2002, 16(1): 1–14

Zaki M A, Rasheed H A, Alkhrdaji T. Performance of CFRP-strengthened concrete beams fastened with distributed CFRP dowel and fiber anchors. Composites. Part B, Engineering, 2019, 176: 107117

Kadhim M M A, Wu Z J, Cunningham L S. Experimental and numerical investigation of CFRP-strengthened steel beams under impact load. Journal of Structural Engineering, 2019, 145(4): 04019004

Benachour A, Benyoucef S, Tounsi A, Addabedia E A. Interfacial stress analysis of steel beams reinforced with bonded prestressed FRP plate. Engineering Structures, 2008, 30(11): 3305–3315

Shaat A, Fam A. Axial loading tests on short and long hollow structural steel columns retrofitted using carbon fibre reinforced polymers. Canadian Journal of Civil Engineering, 2006, 33(4): 458–470

Harries K A, Peck A J, Abraham E J. Enhancing stability of structural steel sections using FRP. Thin-walled Structures, 2009, 47(10): 1092–1101

Lesani M, Bahaari M R, Shokrieh M M. Numerical investigation of FRP-strengthened tubular T-joints under axial compressive loads. Composite Structures, 2013, 100: 71–78

Lesani M, Bahaari M R, Shokrieh M M. FRP wrapping for the rehabilitation of Circular Hollow Section (CHS) tubular steel connections. Thin-walled Structures, 2015, 90: 216–234

Fu Y G, Tong L W, He L, Zhao X L. Experimental and numerical investigation on behavior of CFRP-strengthened circular hollow section gap K-joints. Thin-walled Structures, 2016, 102: 80–97

Aguilera J, Fam A. Retrofitting tubular steel T-joints subjected to axial compression in chord and brace members using bonded FRP plates or through-wall steel bolts. Engineering Structures, 2013, 48: 602–610

Zahedi L, Vatani Oskouei A. A numerical study on steel tubes wrapped with CFRP Laminates: Carbon Fibre Reinforced Polymers applications on offshore marine structures. International Journal of the Constructed Environment, 2013, 3(3): 75–86

Haddad R H. Hybrid repair configurations with CFRP composites for recovering structural performance of steel-corroded beams. Construction & Building Materials, 2016, 124: 508–518

Wu Y F, Yun C, Wei Y Y, Zhou Y W. Effect of predamage on the stress-strain relationship of confined concrete under monotonic loading. Journal of Structural Engineering, 2014, 140(12): 04014093

Dalgic K D, Ispir M, Ilki A. Cyclic and monotonic compression behavior of CFRP-jacketed damaged non-circular concrete prisms. Journal of Composites for Construction, 2016, 20(1): 04015040

Gong Y Z, Liu M T, Li H, Tan T. Flexural behavior of existing damaged RC plate girders strengthened with CFRP sheets. Journal of Tianjin University (Science and Technology), 2018, 51(12): 1246–1252 (in Chinese)

Kenta N, Chikako F, Tsutomu N. Damage mechanism of existing RC slabs with reinforcing steel plate. MATEC Web of Conferences, 2019, 258: 05011

Gao P, Wang J, Li Z Y, Hong L, Wang Z L. Effects of predamage on the compression performance of CFRP-confined rectangular steel reinforced concrete columns. Engineering Structures, 2018, 162: 109–120

Vanlanduit S, Vanherzeele J, Longo R, Guillaume R. A digital image correlation method for fatigue test experiments. Optics and Lasers in Engineering, 2009, 47(3–4): 371–378

Rabczuk T, Belytschko T. Cracking particles: A simplified meshfree method for arbitrary evolving cracks. International Journal for Numerical Methods in Engineering, 2004, 61(13): 2316–2343

Rabczuk T, Belytschko T. A three-dimensional large deformation meshfree method for arbitrary evolving cracks. Computer Methods in Applied Mechanics and Engineering, 2007, 196(29–30): 2777–2799

Rabczuk T, Zi G, Bordas S, Nguyen-Xuan H. A simple and robust three-dimensional cracking-particle method without enrichment. Computer Methods in Applied Mechanics and Engineering, 2010, 199(37–40): 2437–2455

Nguyen-Xuan H, Rabczuk T. Adaptive selective ES-FEM limit analysis of cracked plane-strain structures. Frontiers of Structural and Civil Engineering, 2015, 9(4): 478–490

Pantelides C P, Nadauld J, Cercone L. Repair of cracked aluminum overhead sign structures with glass fiber reinforced polymer composites. Journal of Composites for Construction, 2003, 7(2): 118–126

Nadauld J D, Pantelides C P. Rehabilitation of cracked aluminum connections with GFRP composites for fatigue stresses. Journal of Composites for Construction, 2007, 11(3): 328–335

Fam A, Witt S, Rizkalla S. Repair of damaged aluminum truss joints of highway overhead sign structures using FRP. Construction & Building Materials, 2006, 20(10): 948–956

CMC (China Ministry of Construction). Technical specification for welding of steel structure of building JGJ81-2002. Beijing: China Architecture and Buildings Press, 2002 (in Chinese)

SAC (Standardization Administration of China). Metallic Materials-Tensile testing-Part 1: Method of Test at Room Temperature GB/T 228.1-2010. Beijing: China Standards Press, 2010 (in Chinese)

Msekh M A, Cuong N H, Zi G, Areias P, Zhuang X, Rabczuk T. Fracture properties prediction of clay/epoxy nanocomposites with interphase zones using a phase field model. Engineering Fracture Mechanics, 2018, 188: 287–299

Hamdia K M, Msekh M A, Silani M, Thai T Q, Budarapu P R, Rabczuk T. Assessment of computational fracture models using Bayesian method. Engineering Fracture Mechanics, 2019, 205: 387–398

Bao Y, Wierzbicki T. On fracture locus in the equivalent strain and stress triaxiality space. International Journal of Mechanical Sciences, 2004, 46(1): 81–98

Zhou T H, Li W C, Guan Y, Bai L. Damage analysis of steel frames under cyclic load based on stress triaxiality. Engineering mechanics, 2014, 31(7): 146–155 (in Chinese)

Liao F F. Study on micro fracture criterion of steel and its prediction for connections ductile fracture. Dissertation for the Doctoral Degree. Shanghai: Tongji University, 2012 (in Chinese)

Wang W, Liao F F, Chen Y Y. Ductile fracture prediction and post-fracture path tracing of steel connections based on micromechanics-based fracture criteria. Engineering mechanics, 2014, 31(3):101–108, 115 (in Chinese)

Shen Z Y. Calculation of the ultimate load bearing capacity of the junction of straight welded pipe. Steel structure, 1991, 14(4): 34–38 (in Chinese)

Acknowledgements

This research work was supported and funded by Shandong Provincial Science and Technology Plan Project (No. J13LG05). The experimental tests were conducted in Shandong Provincial Key Laboratory of Civil Engineering Disaster Prevention and Mitigation at Shandong University of Science and Technology. The writers gratefully acknowledge the help of the laboratory staff.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, P., Yang, B., Chen, X. et al. Experimental and numerical investigations of the compressive behavior of carbon fiber-reinforced polymer-strengthened tubular steel T-joints. Front. Struct. Civ. Eng. 14, 1215–1231 (2020). https://doi.org/10.1007/s11709-020-0663-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-020-0663-y