Abstract

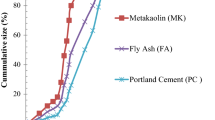

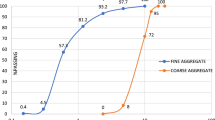

The purpose of the investigation was to study the effect of binary and ternary blends of cement on the mechanical properties of pervious concrete (PC) specimen through destructive (DT) and non-destructive testing (NDT). Various combinations of fly ash (FA), limestone powder (LP), metakaolin (MK), and silica fume (SF) as mineral admixtures have been investigated to partially replace the cement up to 30% by weight in PC. Standard cube specimens of size 150 mm × 150 mm × 150 mm of binary and ternary blends of mineral admixture of pervious concrete were prepared to conduct standard compressive strength test and split tensile test at 7 and 28 days of curing. The ultrasonic pulse velocity (UPV) test and Rebound Hammer test were used as a non-destructive testing tool to substantiate the robustness of PC and to determine the approximate mechanical properties where other destructive testing tools are not feasible in case of in-place pervious pavements. Overall the pervious concrete made with LP based ternary blends (PLM and PLS) were found to perform better than FA based ternary blends (PFM and PFS) and control mix (PC) in destructive and non-destructive testing.

Similar content being viewed by others

References

ACI 522R-10. Report on Pervious Concrete. Farmington Hills, MI: American Concrete Institute, 2010 (Reapproved 2011)

Neithalath N, Sumanasooriya M S, Deo O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Materials Characterization, 2010, 61(8): 802–813

Yekkalar M, Haselbach L, Langfitt Q. Testing development of different surface treatments on pervious concrete. Frontiers of Structural and Civil Engineering, 2016, 10(4): 385–393

Obla K H. Pervious concrete—An overview. Indian Concrete Journal, 2008, 84(8): 9–18

Nguyen D H, Sebaibi N, Boutouil M, Leleyteb L, Baraud F. A modified method for the design of pervious concrete mix. Construction & Building Materials, 2014, 73: 271–282

Torres A, Hu J, Ramos A. The effect of the cementitious paste thickness on the performance of pervious concrete. Construction & Building Materials, 2015, 95: 850–859

Yahia A, Kabagire K D. New approach to proportion pervious concrete. Construction & Building Materials, 2014, 62: 38–46

Bonicelli A, Giustozzi F, Crispino M. Experimental study on the effects of fine sand addition on differentially compacted pervious concrete. Construction & Building Materials, 2015, 91: 102–110

Maguesvari M U, Narasimha V L. Studies on characterization of pervious concrete for pavement applications. Procedia: Social and Behavioral Sciences, 2013, 104: 198–207

Giustozzi F. Polymer modified pervious concrete for durable and sustainable transportation infrastructures. Construction & Building Materials, 2016, 111: 502–512

Aamer Rafique Bhutta M, Hasanah N, Farhayu N, Hussin M W, Tahir M M, Mirza J. Properties of porous concrete from waste crushed concrete (recycled aggregate). Construction & Building Materials, 2013, 47: 1243–1248

Peng H, Yin J, Song W. Mechanical and hydraulic behaviors of ecofriendly pervious concrete incorporating fly ash and blast furnace slag. Applied Sciences, 2018, 8(6): 859

Arezoumandi M, Volz J S. Effect of fly ash replacement level on the fracture behavior of concrete. Frontiers of Structural and Civil Engineering, 2013, 7(4): 411–418

Siddique R. Utilization of silica fume in concrete: Review of hardened properties. Resources, Conservation and Recycling, 2011, 55: 923–932

Turkel S, Altuntas Y. The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars. Sadhana, 2009, 34(2): 331–343

De Weerdt K, Haha M B, Le Saout G, Kjellsen K O, Justnes H, Lothenbach B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cement and Concrete Research, 2011, 41(3): 279–291

Siddique R, Klaus J. Influence of metakaolin on the properties of mortar and concrete: A review. Applied Clay Science, 2009, 43(3–4): 392–400

Mehta P K, Gjorv O E. Properties of Portland cement concrete containing fly ash and condensed silica fume. Cement and Concrete Research, 1982, 12(5): 587–595

Ozyildirim C, Halstead W J. Improved concrete quality with combinations of fly ash and silica fume. American Concrete Institute. Material Journal, 1994, 91(6): 587

Thomas M D A, Shehata M H, Shashiprakash S G, Hopkins D S, Cail K. Use of ternary cementitious systems containing silica fume and fly ash in concrete. Cement and Concrete Research, 1999, 29(8): 1207–1214

Lane D S, Ozyildirim C. Preventive measures for alkali-silica reactions (binary and ternary systems). Cement and Concrete Research, 1999, 29(8): 1281–1288

Shannag M J. High strength concrete containing natural pozzolan and silica fume. Cement and Concrete Composites, 2000, 22(6): 399–406

Nesvijski E G. Dry point contact transducers: Design for new applications. The e-Journal of Nondestructive Testing, 2003, 9: ID–1745

Shah S, Subramaniam K V, Popov J S. Compressive strength, use of nondestructive ultrasonic techniques for material assessment and inservice monitoring of concrete structures. In: Proceedings of the International Symposium on Nondestructive Testing Contribution to the Infrastructure Safety Systems in the 21st Century. Torres: Universidade Federal de Santa Maria, 1999, 107–114

Saint-Pierre F, Philibert A, Giroux B, Rivard P. Concrete quality designation based on ultrasonic pulse velocity. Construction & Building Materials, 2016, 125: 1022–1027

Lorenzi A, Caetano L F, Chies J A, Pinto da Silva Filho L C. Investigation of the potential for evaluation of concrete flaws using nondestructive testing methods. International Scholarly Research Notices Civil Engineering, 2014, 2014: 543090

Mandal T, Tinjum J M, Edil T B. Non-destructive testing of cementitiously stabilized materials using ultrasonic pulse velocity test. Transportation Geotechnics, 2016, 6: 97–107

Panzera T H, Cota F P, Borges P H, Bowen C R. Advances in Composite Materials—Analysis of Natural and Man-Made Materials. Rijeka: InTech, 2011

Gehlot T, Sankhla S S, Gehlot S S, Gupta A. Study of concrete quality assessment of structural elements using ultrasonic pulse velocity test. Journal of Mechanical and Civil Engineering, 2016, 13(5): 15–22

Ćosić K, Korat L, Ducman V, Netinger I. Influence of aggregate type and size on properties of pervious concrete. Construction & Building Materials, 2015, 78: 69–76

Indian Standard. IS: 8112. Ordinary Portland Cement, 43 Grade Specifications. New Delhi: Bureau of Indian Standards, 2013

Indian Standard. IS: 2386. Methods of Test for Aggregates for Concrete. Part I: Particle Size and Shape. New Delhi: Bureau of Indian Standards, 1999

Indian Standard. IS: 383. Specifications for Coarse and Fine Aggregates from Natural Sources for Concrete. New Delhi: Bureau of Indian Standards, 2016

Gurbir K, Singh S P, Kaushik S K. Fatigue analysis of fibrous concrete with cement additions. Construction Materials, 2013, 167(2): 79–90

ASTM C1688. Standard Test Method for Density and Void Content of Freshly Mixed Pervious Concrete. West Conshohocken: ASTM International, 2012

Lian C, Zhuge Y. Optimum mix design of enhanced permeable concrete—An experimental investigation. Construction & Building Materials, 2010, 24(12): 2664–2671

Indian Standard. IS: 516. Methods of tests for strength of concrete. New Delhi: Bureau of Indian Standards, 2016

Indian Standard. IS: 5816. Method of Test Splitting Tensile Strength of Concrete. New Delhi: Bureau of Indian Standards, 1999

Ghambhir M L. Concrete Technology. 3rd ed. Patiala: Tata McGraw-Hill Education, 2004

Indian Standard. IS: 13311-1. Method of Non-Destructive Testing of Concrete, Part 1: Ultrasonic Pulse Velocity. New Delhi: Bureau of Indian Standards, 1992

Chandrappa A K, Biligiri K P. Influence of mix parameters on pore properties and modulus of pervious concrete: An application of ultrasonic pulse velocity. Material and Structure, 2016, 49(12): 5255–5271

Indian Standard. IS: 13311-2: Method of Non-Destructive Testing of Concrete-Methods of Test, Part 2: Rebound Hammer. New Delhi: Bureau of Indian Standards, 1992

Neville A M. Properties of concrete. 4th ed. London: Pearson education, 2011

Moesgaard M, Poulsen S L, Herfort D, Steenberg M, Kirkegaard L F, Skibsted J, Yue Y. Hydration of blended Portland cements containing calcium aluminosilicate glass powder and limestone. Journal of the American Ceramic Society, 2012, 95(1): 403–409

Moser R D, Jayapalan A R, Garas V Y, Kurtis K E. Assessment of binary and ternary blends of metakaolin and class C fly ash for alkali-silica reaction mitigation in concrete. Cement and Concrete Research, 2010, 40(12): 1664–1672

Joshaghani A, Ramezanianpour A A, Ataei O, Golroo A. Optimizing pervious concrete pavement mixture design by using the Taguchi method. Construction and Building Materials, 2015, 101: 317–325

Tennis P, Leming M, Akers D. Pervious Concrete Pavements, National Ready Mixed Concrete Association (NRMCA) 2004. Portland Cement Association Skokie Illinois and National Ready Mixed Concrete Association. Maryland: Silver Spring, 2004

Hannachi S, Guetteche M N. Review of the rebound hammer method estimating concrete compressive strength on site. In: Proceedings of International Conference on Architecture and Civil Engineering. Dubai: Conference Publishing Services, 2014, 118–127

Acknowledgements

The authors gratefully acknowledge the support of Prof. S. P. Singh and other staff members of Concrete Structures Laboratories at Dr B. R Ambedkar National Institute of Technology, Jalandhar, India, during the experimentation work reported in the present investigation. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R., Goel, S. Experimental investigation on mechanical properties of binary and ternary blended pervious concrete. Front. Struct. Civ. Eng. 14, 229–240 (2020). https://doi.org/10.1007/s11709-019-0597-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-019-0597-4