Abstract

This paper presents a literature review focused on the material performance of cold-formed, carbon steel, hollow structural sections under impulsive (highly dynamic) loading. Impulsive loading, represented by impact and blast, is characterized by a very rapid, time-dependent loading regime in the affected members and materials. Thus, the effect of high-strain-rate loading is initially reviewed. Next the material toughness, an important energy-absorption property and one measure of a material’s ability to arrest fracture, is considered by means of studying the Charpy V-notch behavior. The response of hollow sections under axial and lateral impact loading is then reviewed.

Studies of blast on hollow sections, most of which fall under the categories of contact/near-field loading or far-field loading are presented. Under large-scale field blast experiments, cold-formed hollow sections have shown excellent behavior. Software for modeling blast loading and structural response, the latter including single degree of freedom analysis and explicit finite element analysis, is described and discussed.

Similar content being viewed by others

References

Liew J Y R. Survivability of steel frame structures subject to blast and fire. Journal of Constructional Steel Research, 2008, 64(7–8): 854–866

Luecke WE, McColskey J D, McCowan C N, Banovic SW, Fields R J, Foecke T J, Siewert T A, Gayle FW. Mechanical properties of structural steels–federal building and fire safety investigation of the world trade center disaster. NIST NCSTAR 1–3D Report, National Institute of Standards and Technology, Gaithersburg, MD, USA, 2005

Gilsanz R, Hamburger R, Barker D, Smith J L, Rahimian A. Design of blast resistant structures. Steel Design Guide No. 26, American Institute of Construction, Chicago, IL, USA, 2013

DOD. Structures to resist the effects of accidental explosions. UFC 3–340–02, Department of Defense, Washington, DC, USA, 2008

ASCE. Design of blast resistant buildings in petrochemical facilities. American Society of Civil Engineers, Reston, VA, USA, 2010

ASCE. Blast protection of buildings. ASCE/SEI 59–11, American Society of Civil Engineers, Reston, VA, USA, 2011

CSA. Design and assessment of buildings subjected to blast loads. S850–12, Canadian Standards Association, Toronto, Canada, 2012

Rao, N R N, Lohrmann, M, Tall, L. Effect of strain rate on the yield stress of structural steel. Journal of Materials, ASTM, Vol. 1, No. 1, Publication No. 293, 1966

Soroushian P, Choi K. Steel mechanical properties at different strain rates. Journal of Structural Engineering, 1987, 113(4): 663–672

Kassar M, Yu W. Effect of strain rate on material properties of sheet steels. Journal of Structural Engineering, 1992, 118(11): 3136–3150

Malvar L J, Crawford J E. Dynamic increase factors for steel reinforcing bars. 28th. Department of Defence Explosive Safety Board Seminar, Orlando, FL, USA, 1998

Filiatrault A, Holleran M. Stress-strain behaviour of reinforcing steel and concrete under seismic strain rates and low temperatures. Materials and Structures, 2001, 34(4): 235–239

Sun M, Packer J A. High strain rate behaviour of cold-formed rectangular hollow sections. Engineering Structures, 2014, 62–63: 181–192

Ritchie C B, Gow M I, Packer J A, Heidarpour A. Mechanical properties of hollow structural sections under elevated strain rates. Proceedings of the 11th Pacific Structural Steel Conference, Shanghai, China, 708–714, 2016

Mirmomeni M, Heidarpour A, Zhao X L, Hutchinson C R, Packer J A, Wu C. Mechanical properties of partially damaged structural steel induced by high strain rate loading at elevated temperatures–An experimental investigation. International Journal of Impact Engineering, 2015, 76: 178–188

Mirmomeni M, Heidarpour A, Zhao X L, Hutchinson C R, Packer J A, Wu C. Fracture behaviour and microstructural evolution of structural mild steel under the multi-hazard loading of high-strainrate load followed by elevated temperature. Construction & Building Materials, 2016, 122: 760–771

Johnson G R, Cook W H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Engineering Fracture Mechanics, 1985, 21(1): 31–48

Cowper G R, Symonds P R. Strain hardening and strain-rate effects in the impact loading of cantilever beams. Division of Applied Mathematics Report, Brown University, Providence, RI, USA, 1957

Elfahal M M, Krauthammer T, Ohno T, Beppu M, Mindess S. Size effect for normal strength concrete cylinders subjected to axial impact. International Journal of Impact Engineering, 2005, 31(4): 461–481

CEB. Concrete structures under impact and impulsive loading. CEB Bulletin 187, Comité Euro-International du Béton, Lausanne, Switzerland, 1988

Xiao Y, Shan J, Zheng Q, Chen B, Shen Y. Experimental studies on concrete filled steel tubes under high strain rate loading. Journal of Materials in Civil Engineering, 2009, 21(10): 569–577

Malvar L J. Review of static and dynamic properties of steel reinforcing bars. Materials Journal. American Concrete Institute, 1988, 95(5): 609–616

Sedlacek G, Feldmann M, Kühn B, Tschickardt D, Höhler S, Müller C, Hensen W, Stranghöner N, Dahl W, Langenberg P, Münstermann S, Brozetti J, Raoul J, Pope R, Bijlaard F. Commentary and Worked Examples to EN 1993–1-10. Material Toughness and Through Thickness Properties and other Toughness Oriented Rules in EN 1993. JRC Scientific and Policy Report No. 47278, European Commission Joint Research Centre, Luxembourg, 2008

Feldmann M, Eichler B, Kühn B, Stranghöner N, Dahl W, Langenberg P, Kouhi J, Pope R, Sedlacek G, Ritakallio P, Iglesias G, Puthli R S, Packer J A, Krampen J. Choice of steel material to avoid brittle fracture for hollow section structures. JRC Scientific and Policy Report No. 72702, European Commission Joint Research Centre, Luxembourg, 2012

Dagg H M, Davis K, Hicks J W. Charpy impact tests on coldformed RHS manufactured from continuous cast fully killed steel. Proceedings of the Pacific Structural Steel Conference, Australian Institute of Steel Construction, Queensland, Australia, 1989

Soininen R. Fracture behaviour and assessment of design requirements against fracture in welded steel structures made of cold-formed hollow sections. Tieteellisiä Julkaisuja Research Papers 52, Lappeenranta University of Technology, Lappeenranta, Finland, 1996

Ritakallio P. Ruukki cold-formed hollow sections–Grade S355J2H–Random samples. Private Communication, Rauterruukki Oyj, Confidential Test Data, 12 April, 2010

Kosteski N, Packer J A, Puthli R S. Notch toughness of coldformed hollow sections. Final (Revision 2) Report to CIDECT on Programme 1B, CIDECT Report 1B–2/03, October, 2003

Puthli R, Herion S, Boellinghaus T, Florian W. Welding in coldformed areas of rectangular hollow sections. Draft Final Report on Programme 1A, CIDECT Report 1A–5/04, March, 2004

Stranghöner N, Lorenz C, Berg J. Zähigkeitsuntersuchungen an warmgefertigten hohlprofilen. Versuchsbericht für Vallourec & Mannesmann, Düsseldorf, Institut für Metall- und Leichtbau, Universität Duisburg-Essen, Germany, 2010

Kosteski N, Packer J A, Puthli R S. Notch toughness of internationally produced hollow structural sections. Journal of Structural Engineering, 2005, 131(2): 279–286

Stranghöner N, Krampen J, Lorenz C. Impact toughness behaviour of hot-finished hollow sections at low temperatures. Proceedings of the 22nd. International Offshore and Polar Engineering Conference, Rhodes, Greece, 118–125, 2012

Sun M, Packer J A. Charpy V-notch impact toughness of coldformed rectangular hollow sections. Journal of Constructional Steel Research, 2014, 97: 114–126

Ritakallio P, Björk T. Low-temperature ductility and structural behaviour of cold-formed hollow section structures–progress during the past two decades. Steel Construction, 2014, 7(2): 107–115

CEN. Cold formed welded structural hollow sections of non-alloy and fine grain steels–Part 1: Technical Delivery Conditions. EN10219–1:2006(E), European Committee for Standardisation, Brussels, Belgium, 2006

CEN. Cold formed welded structural hollow sections of non-alloy and fine grain steels–Part 2: Tolerances. EN10219–2:2006(E), European Committee for Standardisation, Brussels, Belgium, 2006

Puthli R, Packer J A. Structural design using cold-formed hollow sections. Steel Construction, 2013, 6(2): 150–157

Sun M, Packer J A. Direct-formed and continuous-formed rectangular hollow sections–Comparison of static properties. Journal of Constructional Steel Research, 2014, 92: 67–78

ASTM. Standard specification for cold-formed welded and seamless carbon steel structural tubing in rounds and shapes. ASTM A500/A500M–13, American Society for Testing and Materials, West Conshohocken, PA, USA, 2013

MOC. Cold formed steel hollow sections for building structures. JG/T 178–2005. Ministry of Construction, Beijing, China, 2005

ASTM. Standard specification for cold-formed welded carbon steel hollow structural sections (HSS). ASTM A1085–13, American Society for Testing and Materials, West Conshohocken, PA, USA, 2013

AASHTO. AASHTO LRFD bridge design specifications. 7th ed, American Association of State Highway and Transportation Officials, Washington, DC, USA, 2016

ASTM. Standard test methods and definitions for mechanical testing of steel products. ASTM A370–09a. American Society for Testing and Materials, West Conshohocken, PA, USA, 2009

Ritakallio P. The effect of steel strip on the quality of cold-formed hollow sections. In: Proceedings of the 15th. International Symposium on Tubular Structures. Rio de Janeiro, Brazil, 605–612, 2015

Bambach M R, Elchalakani M. Plastic mechanism analysis of steel SHS strengthened with CFRP under large axial deformation. Thinwalled Structures, 2007, 45(2): 159–170

Abramowicz W, Jones N. Dynamic axial crushing of square tubes. International Journal of Impact Engineering, 1984, 2(2): 179–208

Kohar C P, Mohammadi M, Mishra R K, Inal K. Effects of elastic–plastic behaviour on the axial crush response of square tubes. Thinwalled Structures, 2015, 93: 64–87

Pipkorn B, Håland Y. Proposed variable stiffness of vehicle longitudinal frontal members. International Journal of Crashworthiness, 2005, 10(6): 603–608

Abramowicz W, Jones N. Transition from initial global bending to progressive buckling of tubes loaded statically and dynamically. International Journal of Impact Engineering, 1997, 19(5–6): 415–437

Grzebieta R H. An alternative method for determining the behaviour of round stocky tubes subjected to an axial crush load. Thin-walled Structures, 1990, 9(1–4): 61–89

Maduliat S, Ngo T D, Tran P, Lumantarna R. Performance of hollow steel tube bollards under quasi-static and lateral impact load. Thin-walled Structures, 2015, 88: 41–47

Chen L, Xiao Y, Xiao G, Liu C L, Agrawal A K. Test and numerical simulation of truck collision with anti-ram bollards. International Journal of Impact Engineering, 2015, 75: 30–39

Yousuf M, Uy B, Tao Z, Remennikov A, Liew J Y R. Transverse impact resistance of hollow and concrete filled stainless steel columns. Journal of Constructional Steel Research, 2013, 82: 177–189

Bambach M R, Jama H, Zhao X L, Grzebieta R H. Hollow and concrete filled steel hollow sections under transverse impact loads. Engineering Structures, 2008, 30(10): 2859–2870

Han L H, Hou C C, Zhao X L, Rasmussen K J R. Behaviour of high-strength concrete filled steel tubes under transverse impact loading. Journal of Constructional Steel Research, 2014, 92: 25–39

Remennikov A M, Kong S Y, Uy B. Response of foam- and concrete-filled square steel tubes under low-velocity impact loading. Journal of Performance of Constructed Facilities, 2011, 25(5): 373–381

Deng Y, Tuan C Y, Xiao Y. Flexural behaviour of concrete-filled circular steel tubes under high-strain rate impact loading. Journal of Structural Engineering, 2012, 138(3): 449–456

Wang R, Han L H, Hou C C. Behavior of concrete filled steel tubular (CFST) members under lateral impact: Experiment and FEA model. Journal of Constructional Steel Research, 2013, 80: 188–201

Wang Y, Qian X D, Liew J Y R, Zhang M H. Experimental behavior of cement filled pipe-in-pipe composite structures under transverse impact. International Journal of Impact Engineering, 2014, 72: 1–16

Wang Y, Qian X D, Liew J Y R, Zhang M H. Impact of cement composite filled steel tubes: An experimental, numerical and theoretical treatise. Thin-walled Structures, 2015, 87: 76–88

Zeinoddini M, Parke G A R, Harding J E. Axially pre-loaded steel tubes subjected to lateral impacts: An experimental study. International Journal of Impact Engineering, 2002, 27(6): 669–690

Jama H H, Bambach M R, Grzebieta R H, Zhao X L. Flexural response of fixed-ended tubular steel beams strengthened with CFRP subjected to impact loads. Proceedings of the 8th International Conference on Steel, Space & Composite Structures, Kuala Lumpur, Malaysia, 229–235, 2006

Wu C Q, Hao H, Deeks A J. Numerical analysis of the two-rail steel RHS traffic barrier to vehicle impact. Australian Journal of Structural Engineering, 2005, 6(1): 63–76

Hao H, Deeks A J, Wu C Q. Numerical simulations of the performance of steel guardrails under vehicle impact. Transactions of Tianjin University, 2008, 14(5): 318–323

Fan Z H, Shen J J, Lu G X, Ruan D. Dynamic lateral crushing of empty and sandwich tubes. International Journal of Impact Engineering, 2013, 53: 3–16

Wang H B, Yang J L, Liu H, Sun Y X, Yu T X. Internally nested circular tube system subjected to lateral impact loading. Thinwalled Structures, 2015, 91: 72–81

Elchalakani M, Zhao X L, Grzebieta R H. Bending tests to determine slenderness limits for cold-formed circular hollow sections. Journal of Constructional Steel Research, 2002, 58(11): 1407–1430

Poonaya S, Teeboonma U, Thinvongpituk C. Plastic collapse analysis of thin-walled circular tubes subjected to bending. Thinwalled Structures, 2009, 47(6–7): 637–645

Elchalakani M, Zhao X L, Grzebieta R H. Plastic mechanism analysis of circular tubes under pure bending. International Journal of Mechanical Sciences, 2002, 44(6): 1117–1143

Al-Thairy H, Wang Y C. An assessment of the current Eurocode 1 design methods for building structure steel columns under vehicle impact. Journal of Constructional Steel Research, 2013, 88: 164–171

Al-Thairy H, Wang Y C. A simplified analytical method for predicting the critical velocity of vehicle impact on steel columns. Journal of Constructional Steel Research, 2014, 92: 136–149

Wegener R B, Martin J B. Predictions of permanent deformation of impulsively loaded simply supported square tube steel beams. International Journal of Mechanical Sciences, 1985, 27(1–2): 55–69

Jama H H, Bambach M R, Nurick G N, Grzebieta R H, Zhao X L. Numerical modelling of square tubular steel beams subjected to transverse blast loads. Thin-walled Structures, 2009, 47(12): 1523–1534

Jama H H, Nurick G N, Bambach M R, Grzebieta R H, Zhao X L. Steel square hollow sections subjected to transverse blast loads. Thin-walled Structures, 2012, 53: 109–122

Bambach M R. Design of metal hollow section tubular columns subjected to transverse blast loads. Thin-walled Structures, 2013, 68: 92–105

Karagiozova D, Yu T X, Lu G. Transverse blast loading of hollow beams with square cross-sections. Thin-walled Structures, 2013, 62: 169–178

Bambach MR. Behaviour and design of aluminum hollow sections subjected to transverse blast loads. Thin-walled Structures, 2008, 46(12): 1370–1381

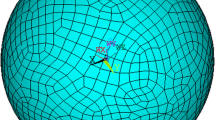

Karagiozova D, Yu T X, Lu G, Xiang X. Response of a circular metallic hollow beam to an impulsive loading. Thin-walled Structures, 2014, 80: 80–90

Bambach M R, Zhao X L, Jama H H. Energy absorbing characteristics of aluminium beams strengthened with CFRP subjected to transverse blast load. International Journal of Impact Engineering, 2010, 37(1): 37–49

Fujikura S, Bruneau M, Lopez-Garcia D. Experimental investigation of multihazard resistant bridge piers having concrete-filled steel tube under blast loading. Journal of Bridge Engineering, 2008, 13(6): 586–594

Remennikov A, Uy B. Explosive testing and modelling of square tubular steel columns for near-field detonations. Journal of Constructional Steel Research, 2014, 101: 290–303

Ngo T, Mohotti D, Remennikov A, Uy B. Numerical simulations of response of tubular steel beams to close-range explosions. Journal of Constructional Steel Research, 2015, 105: 151–163

Song K, Long Y, Ji C, Gao F. Plastic deformation of metal tubes subjected to lateral blast loads. Mathematical Problems in Engineering, 2014

Zhang F, Wu C, Wang H, Zhou Y. Numerical simulation of concrete filled steel tube columns against BLAST loads. Thinwalled Structures, 2015, 92: 82–92

Zhang F, Wu C, Li Z X, Zhao X L. Residual axial capacity of CFDST columns infilled with UHPFRC after close-range blast loading. Thin-walled Structures, 2015, 96: 314–327

Zhang F, Wu C, Zhao X L, Xiang H, Li Z X, Fang Q, Liu Z, Zhang Y, Heidarpour A, Packer J A. Heidarpour, A., Packer, J A. Experimental study of CFDST columns infilled with UHPC under close-range blast loading. International Journal of Impact Engineering, 2016, 93: 184–195

Zhang F, Wu C, Zhao X L, Heidarpour A, Li Z. Experimental and numerical study of blast resistance of square CFDST columns with steel-fibre reinforced concrete. Engineering Structures, 2017 (in press)

Chen W, Guo Z, Zhang T, Zou H, Gu J. Near-field blast test on reactive powder concrete-filled steel tubular columns after exposure to fire. International Journal of Protective Structures, 2016, 7(2): 193–212

Clubley S K. Steel sections subject to a long-duration blast. Structures and Buildings. Institution of Civil Engineers, 2012, 166 (SB6): 273–281

Zhai X, Wang Y, Huang M. Performance and protection approach of single-layer reticulated dome subjected to blast loading. Thinwalled Structures, 2013, 73: 57–67

Ding Y, Wang M, Li Z X, Hao H. Damage evaluation of the steel tubular column subjected to explosion and post-explosion fire condition. Engineering Structures, 2013, 55: 44–55

Walker M, Ritchie C, Spiller K, Seica M V, Packer J A, Eytan A. Challenges and outcome of fullscale blast experimentation on structural steel members and glass elements. In: Proceedings of the 15th International Symposium on Interaction of the Effects of Munitions with Structures, Potsdam, Germany, Paper No. 126, 2013

Ritchie C, Packer J A, Seica M, Yankelevsky D. Field blast testing and SDOF analysis of unfilled and concrete-filled RHS members. In: Proceedings of the 23rd. International Symposium on Military Aspects of Blast and Shock, Oxford, United Kingdom, Paper No. 31, 2014

Ritchie C, Packer J A, Seica M, Zhao X L. Field blast testing and FE modelling of concrete-filled RHS members. In: Proceedings of the 3rd. International Conference on Protective Structures. Newcastle, Australia, 478–485, 2015

Ritchie C, Packer J A, Seica M, Zhao X L. Field blast testing and FE modelling of RHS members. In: Proceedings of the 15th International Symposium on Tubular Structures. Rio de Janeiro, Brazil, 211–218, 2015

Ritchie C, Packer J A, Seica M, Zhao X L. Field blast testing of concrete-filled double-skin tube members. In: Proceedings of the 4th International Conference on Protective Structures. Beijing, China, 546–555, 2016

Theobald M D, Nurick G N. Experimental and numerical analysis of tube-core claddings under blast loads. International Journal of Impact Engineering, 2010, 37(3): 333–348

Shen J, Lu G, Zhao L, Zhang Q. Short sandwich tubes subjected to internal explosive loading. Engineering Structures, 2013, 55: 56–65

Langdon G S, Ozinsky A, Chung Kim Yuen S. The response of partially confined right circular stainless steel cylinders to internal air-blast loading. International Journal of Impact Engineering, 2014, 73: 1–14

Hyde D. Microcomputer programs CONWEP and FUNPRO, applications of TM 5–855–1. Fundamentals of Protective Design for Conventional Weapons. (User’s Guide). U.S. Army Corps of Engineers Waterways Experiment Station, Vicksburg, MS, USA, 1988

USACE. Single-degree-of-freedom blast effects design spreadsheets (SBEDS). PDC-TR 05–01. U.S. Army Corps of Engineers, USA, 2005

LSTC. LS-DYNA Theory Manual. Livermore Software Technology Corporation, Livermore, CA, USA, 2014

Simulia. ABAQUS Theory Manual. Providence, RI, USA, 2014

ANSYS. ANSYS Autodyn user’s guide. Canonsburg, PA, USA, 2015

Acknowledgments

The authors would like to acknowledge the financial support of the Comité International pour le Développement et l’ Étude de la Construction Tubulaire (CIDECT) Programme 16G, the Natural Sciences and Engineering Research Council of Canada (NSERC), Explora Foundation, and the Tsinghua Initiative Scientific Research Program (No. 20131089347).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ritchie, C.B., Packer, J.A., Zhao, XL. et al. Dynamic material performance of cold-formed steel hollow sections: a state-of-the-art review. Front. Struct. Civ. Eng. 11, 209–227 (2017). https://doi.org/10.1007/s11709-017-0388-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-017-0388-8