Abstract

Geopolymer, an inorganic aluminosilicate material activated by alkaline medium solution, can perform as an inorganic adhesive. The geopolymer technology has a viability to substitute traditional concrete made of portland cement (PC) because replacing PC with fly ash leads to reduced carbon dioxide emissions from cement productions and reduced materials cost. Although fly ash geopolymer stimulates sustainability, it is slow geopolymerization reaction poses a challenge for construction technology in term of practicality. The development of increasing geopolymerization reaction rate of the geopolymer is needed.

The purpose of this study is to evaluate seeding nucleation agents (NA) of fly ash geopolymer that can accelerate polymerization reactions such that the geopolymer can be widely used in the construction industry. Results from the present study indicate that the use of NA (i.e., Ca(OH)2) can be potentially used to increase geopolymerization reaction rate and improve performance characteristics of the fly ash geopolymer product.

Similar content being viewed by others

References

Horvath A. Construction materials and the environment. Environment and Resources, 2004, 29: 181–204

Vassilev S V, Menendez R, Alvarez D, Diaz-Somoano M, Martinez-Tarazona M R. Phase-mineral and chemical composition of coal fly ashes as a basis for their multicomponent utilization. 1. Characterization of feed coals and fly ashes. Fuel, 2003, 82(14): 1793–1811

Williams R P, van Riessen A. Determination of the reactive component of fly ashes for geopolymer production using XRF and XRD. Fuel, 2010, 89(12): 3683–3692

Ahmaruzzaman M, Gupta V K. Rice husk and its ash as low-cost adsorbents in water and wastewater treatment. Industrial & Engineering Chemistry Research, 2011, 50(24): 13589–13613

Erol M, Küçükbayrak S, Ersoy-Meriçboyu A. Characterization of coal fly ash for possible utilization in glass production. Fuel, 2007, 86(5–6): 706–714

Haynes R J. Reclamation and revegetation of fly ash disposal sites–Challenges and research needs. Journal of Environmental Management, 2009, 90(1): 43–53

Fernández-Jimenez A, de la Torre A G, Palomo A, López-Olmo G, Alonso M M, Aranda M A G. Quantitative determination of phases in the alkali activation of fly ash. Part I. Potential ash reactivity. Fuel, 2006, 85(5–6): 625–634

Dermatas D, Meng X. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Engineering Geology, 2003, 70(3–4): 377–394

Somna K, Jaturapitakkul C, Kajitvichyanukul P, Chindaprasirt P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel, 2011, 90(6): 2118–2124

Davidovits J. Geopolymer Chemistry and Applications. 2nd ed. Institue Geopolymere, Saint-Quentin, France, 2008

Panias D, Giannopoulou I P, Perraki T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids and Surfaces. A. Physicochemical and Engineering Aspects, 2007, 301(1–3): 246–254

Gartner E. Industrially interesting approaches to “low-CO2” cements. Cement and Concrete Research, 2004, 34(9): 1489–1498

Juenger M C G, Winnefeld F, Provis J L, Ideker J H. Advances in Alternative Cementitious Binders, 2010

Li Q, Xu H, Li F, Li P, Shen L, Zhai J. Synthesis of geopolymer composites from blends of CFBC fly and bottom ashes. Fuel, 2012, 97: 366–372

McLellan B C, Williams R P, Lay J, van Riessen A, Corder G D. Cost and carbon emissions for geopolymer pastes in comparison to ordianry portland cement. Journal of Cleaner Production, 2011, 19 (9–10): 1080–1090

Schmücker M, MacKenzie K J D. Microstructure of sodium polysialate siloxo geopolymer. Ceramics International, 2005, 31(3): 433–437

Ismael M R, dos Anjos R D, Salomao R, Pandolfelli V C. Colloidal silica as a nanostructured binder for refractory castables. Refractories App, 2006, 11: 16–20

Phair J W, van Deventer J S J. Characterization of fly-ash-based geopolymeric binders activated with sodium aluminate. Industrial & Engineering Chemistry Research, 2002, 41(17): 4242–4251

Kong D L Y, Sanjayan J G, Sagoe-Crentsil K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cement and Concrete Research, 2007, 37(12): 1583–1589

Chindaprasirt P, Chareerat T, Sirivivatnanon V. Workability and strength of coarse high calcium fly ash geopolymer. Cement and Concrete Composites, 2007, 29(3): 224–229

Sumajouw D M, Hardjito D, Wallah S E, Rangan B V. Fly ash-based geopolymer concrete: Study of slender reinforced columns. Journal of Materials Science, 2007, 42(9): 3124–3130

Lee WK W, van Deventer J S J. The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements. Cement and Concrete Research, 2002, 32(4): 577–584

Duxson P, Lukey G C, van Deventer J S J. Thermal conductivity of metakaolin geopolymers used as a first approximation for determining gel interconnectivity. Industrial & Engineering Chemistry Research, 2006, 45(23): 7781–7788

Hardjito D, Rangan B V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete. Curtin University of Technology, Perth, Australia, 2005

Palomo A, Blanco-Varela M T, Granizo M L, Puertas F, Vazquez T, Grutzeck M W. Chemical stability of cementitious materials based on metakaolin. Cement and Concrete Research, 1999, 29(7): 997–1004

Fernandez-Jimenez A, Garcia-Lodeiro I, Palomo A. Durability of alkali-activated fly ash cementitious materials. Journal of Materials Science, 2007, 742(9): 3055–3065

Puertas F, Martinez-Ramirez S, Alonso S, Vazquez T. Alkaliactivated fly ash/slag cement: Strength behaviour and hydration products. Cement and Concrete Research, 2000, 30: 1625–1632

Haddad R H, Alshbuol O. Production of geopolymer concrete using natural pozzolan: A parametric study. Construction & Building Materials, 2016, 114: 699–707

Albitar M, Mohamed Ali M S, Visintin P, Drechsler M. Effect of granulated lead smelter slag on strength of fly ash-based geopolymer concrete. Construction & Building Materials, 2015, 83: 128–135

Adam A A, Horianto X X X. The effect of temperature and duration of curing on the strength of fly ash based geopolymer mortar. Procedia Engineering, 2014, 95: 410–414

Arioz E, Arioz O, Mete Kockar O. An experimental study on the mechanical and microstrutural properties of geopolymers. Procedia Engineering, 2012, 42: 100–105

Albitar M, Visintin P, Ali M M, Drechsler M. Assessing behaviour of fresh and hardened geopolymer concrete mixed with class-F fly ash. KSCE Journal of Civil Engineering, 2015, 19(5): 1445–1455

Oh J E, Monteiro P J M, Jun S S, Choi S, Clark M. The evolution of strength and crystalline phases for alkali-activated groud blast furnance slag and fly ash-based geopolymers. Cement and Concrete Research, 2010, 40(2): 189–196

Nazari A, Sanjayan J. Handbook of Low Carbon Concrete. Butterworth-Heinemann, 2016

Young J R, How M J, Walker A P, Worth W M H. Classification as corrosive or irritant to skin of preparations containing acidic or alkaline substances without testing on animals. Toxicology in Vitro, 1988, 2(1): 19–26

Currell B R, Grzeskowilak R, Midgley H G, Parsonage J R. The acceleration and retardation of set high alumina cement by additives. Cement and Concrete Research, 1987, 17(3): 420–432

Damidot D, Rettel A, Capmas A. Action of admixtures on fondu cement: Part I lithium and sodium salts compared. Advances in Cement Research, 1996, 8(31): 111–119

Novinson T, Crahan J. Lithium salts as set accelerators for refractory concretes: Correlation of chemical properties with setting times. ACI Materials Journal, 1988, 85: 12–16

Luong T, Mayer H, Eckert H, Novinson T I. In situ 27Al NMR studies of cement hydration: The effect of lithium-containing setting accelerations. Journal of the American Ceramic Society, 1989, 72 (11): 2136–2141

Matusinovic T, Curlin D. Lithium salts as set accelerators for high alumina cement. Cement and Concrete Research, 1993, 23(4): 885–895

Wang H, Eubanks K, Fitch B, Manissero C, Marin F. Effective use of lithium-based admixtures for set control of cementitious system. ACI-Special Pub, 1997, 173: 893–908

Millard M J, Kurtis K E. Effects of lithium nitrate admixture on early-age cement hydration. Cement and Concrete Research, 2008, 38(4): 500–510

O’Connor S J, MacKenzie K J D. Synthesis, characterisation and thermal behaviour of lithium aluminosilicate inorganic polymers. Journal of Materials Science, 2010, 45(14): 3707–3713

Jang H M, Kim K S, Jung C J. Chemical processing and densification characteristics of lithium aluminosilicate (LAS) gels. Journal of Materials Research, 1992, 7(08): 2273–2280

Rodger S A, Double D D. The chemistry of hydration of high alumina cement in the presence of accelerating and retarding admixtures. Cement and Concrete Research, 1984, 14(1): 73–82

Dove P M, Nix C J. The influence of the alkaline earth cations, magnesium, calcium, and barium on the dissolution kinetics of quartz. Geochemi. Cosmoch. Acta, 1997, 61(16): 3329–3340

Dove P M, Elston S F. Dissolution kinetics of quartz in sodium chloride solutions: Analysis of existing data and a rate model for 25° C. Geochemi Cosmoch Acta, 1992, 56(12): 4147–4156

Barker P, Fontes J C, Gasse F, Druart J C. Experimental dissolution of diatom silica in concentrated salt solutions and implications for paleoenviromental reconstruction. Limnology and Oceanography, 1994, 39(1): 99–110

Kamiya H, Shimokata K. The role of salts in the dissolution of powdered quartz. In: Cadek J, Paces T. eds. In: Proceedings of the International Symposium on Water-rock Interaction. Czechoslovakian Geol, Survey, Prague, 1976

House W A. The role of surface complexation in the dissolution kinetics of silica: Effects of monovalent and divalent ions at 25°C. Journal of Colloid & Interface Science, 1994, 163(2): 379–390

Rattanasak U, Pankhet K, Chindaprasirt P. Effect of chemical admixtures on properties of high-calcium fly ash geopolymer. International Journal of Minerals Metallurgy and Materials, 2011, 18(3): 364–369

Temuujin J, van Riessen A, Williams R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. Journal of Hazardous Materials, 2009, 167(1-3): 82–88

van Deventer J S J, Provis J L, Duxson P, Lukey G C. Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products. Journal of Hazardous Materials, 2007, 139(3): 506–513

Davidotvits J. Geopolymers: Inorganic polymeric new materials. J Mater Eng, 1994, 16: 91–139

Lin S T, Huang R. Application of Ultrasonic Method for Determining Set Times of VMA Modified Cementitious Composites. In: Buyukozturk O, Tademir MA, eds. Nondestructive Testing of Materials and Structures, RILEM Bookseries, Istanbul, Turkey, 2012, 473–477

Nmai C K. Cementitious materials for concrete. ACI Educat. Bulltin E 3–01. ACI, 2001, 25

Trejo D, Prasittisopin L. Effects of mixing variables on early-age characteristics of portland cement systems. Journal of Materials in Civil Engineering, 2016, 28(10): 04016094

EN 1992–1-1 (2004): Eurocode 2: Design of concrete structures–Part 1–1: General rules and rules for buildings, Authority: The European Union Per Regulation 305/2011. Directive 98/34/EC, Directive 2004/18/EC

Standard for fresh concrete–The application of BS EN 206–1 and BS 8500, British Standard Institution, 2004

Details and Detailing of Concrete Reinforcement. (ACI 315–99), American Concrete Institute, 1999

Acknowledgements

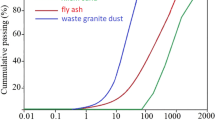

The authors wish to thank the school of Civil and Construction Engineering at Oregon State University for some of the laboratory equipment in this study, Dr. Thomas Shellhammer, Department of Food Science & Technology, Oregon State University for advising the use of the particle size analyzer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasittisopin, L., Sereewatthanawut, I. Effects of seeding nucleation agent on geopolymerization process of fly-ash geopolymer. Front. Struct. Civ. Eng. 12, 16–25 (2018). https://doi.org/10.1007/s11709-016-0373-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-016-0373-7