Abstract

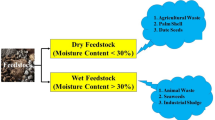

The reuse of biomass wastes is crucial toward today’s energy and environmental crisis, among which, biomass-based biochar as catalysts for biofuel and high value chemical production is one of the most clean and economical solutions. In this paper, the recent advances in biofuels and high chemicals for selective production based on biochar catalysts from different biomass wastes are critically summarized. The topics mainly include the modification of biochar catalysts, the preparation of energy products, and the mechanisms of other high-value products. Suitable biochar catalysts can enhance the yield of biofuels and higher-value chemicals. Especially, the feedstock and reaction conditions of biochar catalyst, which affect the efficiency of energy products, have been the focus of recent attentions. Mechanism studies based on biochar catalysts will be helpful to the controlled products. Therefore, the design and advancement of the biochar catalyst based on mechanism research will be beneficial to increase biofuels and the conversion efficiency of chemicals into biomass. The advanced design of biochar catalysts and optimization of operational conditions based on the biomass properties are vital for the selective production of high-value chemicals and biofuels. This paper identifies the latest preparation for energy products and other high-value chemicals based on biochar catalysts progresses and offers insights into improving the yield of high selectivity for products as well as the high recyclability and low toxicity to the environment in future applications.

Similar content being viewed by others

References

Pang S. Advances in thermochemical conversion of woody biomass to energy, fuels and chemicals. Biotechnology Advances, 2019, 37(4): 589–597

Bridgwater A V, Meier D, Radlein D. An overview of fast pyrolysis of biomass. Organic Geochemistry, 1999, 30: 1479–1493

Chen Z, Wang M, Jiang E, et al. Pyrolysis of torrefied biomass. Trends in Biotechnology, 2018, 36(12): 1287–1298

Patel S, Kundu S, Halder P, et al. A critical literature review on biosolids to biochar: An alternative biosolids management option. Reviews in Environmental Science and Biotechnology, 2020, 19(4): 807–841

Kabir G, Hameed B H. Recent progress on catalytic pyrolysis of lignocellulosic biomass to high-grade bio-oil and bio-chemicals. Renewable & Sustainable Energy Reviews, 2017, 70: 945–967

Li S, Li S, Wang C, et al. Catalytic effects of ammonium dihydrogen phosphate on the pyrolysis of lignocellulosic biomass: Selective production of furfural and levoglucosenone. Fuel Processing Technology, 2020, 209: 106525

Kim M, Fernando J F S, Li Z, et al. Ultra-stable sodium ion storage of biomass porous carbon derived from sugarcane. Chemical Engineering Journal, 2022, 445: 136344

Velusamy K, Devanand J, Senthil Kumar P, et al. A review on nano-catalysts and biochar-based catalysts for biofuel production. Fuel, 2021, 306: 121632

Zhou X, Zhu Y, Niu Q, et al. New notion of biochar: A review on the mechanism of biochar applications in advanced oxidation processes. Chemical Engineering Journal, 2021, 416: 129027

Kim M, Firestein K L, Fernando J F S, et al. Strategic design of Fe and N co-doped hierarchically porous carbon as superior ORR catalyst: From the perspective of nanoarchitectonics. Chemical Science (Cambridge), 2022, 13(36): 10836–10845

Afolabi A T F, Kechagiopoulos P N, Liu Y, et al. Kinetic features of ethanol steam reforming and decomposition using a biochar-supported Ni catalyst. Fuel Processing Technology, 2021, 212: 106622

Tao W, Zhang P, Li H, et al. Generation mechanism of persistent free radicals in lignocellulose-derived biochar: Roles of reducible carbonyls. Environmental Science & Technology, 2022, 56(15): 10638–10645

Kim M, Lim H, Xu X, et al. Sorghum biomass-derived porous carbon electrodes for capacitive deionization and energy storage. Microporous and Mesoporous Materials, 2021, 312: 110757

Ren J, Liu Y L. Direct conversion of syngas produced from steam reforming of toluene into methane over a Ni/biochar catalyst. ACS Sustainable Chemistry & Engineering, 2021, 9(33): 11212–11222

Boggula R R, Fischer D, Casaretto R, et al. Methanation potential: Suitable catalyst and optimized process conditions for upgrading biogas to reach gas grid requirements. Biomass and Bioenergy, 2020, 133: 105447

Yue X, Chen D, Luo J, et al. Direct synthesis of methane-rich gas from reed biomass pyrolysis volatiles over its biochar-supported Ni catalysts. Biomass and Bioenergy, 2021, 154: 106250

Wang Y, Shao Y, Zhang L, et al. Co-presence of hydrophilic and hydrophobic sites in Ni/biochar catalyst for enhancing the hydrogenation activity. Fuel, 2021, 293: 120426

González-Castao M, Morales C, Miguel J C N D, et al. Are Ni/and Ni5Fe1/biochar catalysts suitable for synthetic natural gas production? A comparison with γ-Al2O3 supported catalysts Green Energy & Environment, 2023, 8(3): 744–756

Quan C, Wang H, Gao N. Development of activated biochar supported Ni catalyst for enhancing toluene steam reforming. International Journal of Energy Research, 2020, 44(7): 5749–5764

Li P, Lin K, Fang Z, et al. Enhanced nitrate removal by novel bimetallic Fe/Ni nanoparticles supported on biochar. Journal of Cleaner Production, 2017, 151: 21–33

Wang Y, Zhang Z, Zhang S, et al. Steam reforming of acetic acid over Ni/biochar catalyst treated with HNO3: Impacts of the treatment on surface properties and catalytic behaviors. Fuel, 2020, 278: 118341

Lestinsky P, Zikmund Z, Grycova B, et al. Production of hydrogen over Ni/carbonaceous catalyst. Fuel, 2020, 278: 118398

Ido A L, de Luna M D G, Ong D C, et al. Upgrading of scenedesmus obliquus oil to high-quality liquid-phase biofuel by nickel-impregnated biochar catalyst. Journal of Cleaner Production, 2019, 209: 1052–1060

Xu B, Lu W, Sun Z, et al. High-quality oil and gas from pyrolysis of Powder River Basin coal catalyzed by an environmentally-friendly, inexpensive composite iron-sodium catalysts. Fuel Processing Technology, 2017, 167: 334–344

Lu Q, Yuan S, Wang X, et al. Coking behavior and syngas composition of the char supported Fe catalyst of biomass pyrolysis volatiles reforming. Fuel, 2021, 298: 120830

Álvarez M L, Gascó G, Palacios T, et al. Fe oxides-biochar composites produced by hydrothermal carbonization and pyrolysis of biomass waste. Journal of Analytical and Applied Pyrolysis, 2020, 151: 104893

Xu Z, Zhou Y, Sun Z, et al. Understanding reactions and poreforming mechanisms between waste cotton woven and FeCl3 during the synthesis of magnetic activated carbon. Chemosphere, 2020, 241: 125120

Zeng Z, Tian X, Wang Y, et al. Microwave-assisted catalytic pyrolysis of corn cobs with Fe-modified Choerospondias axillaris seed-based biochar catalyst for phenol-rich bio-oil. Journal of Analytical and Applied Pyrolysis, 2021, 159: 105306

Xue N, Wang Z, Wu J, et al. Effect of equivalence ratio on the CO selectivity of Fe/Ca-based oxygen carriers in biomass char chemical looping gasification. Fuel, 2019, 252: 220–227

Sun L, Wang Z, Chen L, et al. Improving the monocyclic aromatic hydrocarbons production from fast pyrolysis of biomass over Fe-modified ZSM-5 catalysts. International Journal of Energy Research, 2021, 45(4): 6032–6040

Zhao B, Li H, Wang H, et al. Synergistic effects of metallic Fe and other homogeneous/heterogeneous catalysts in hydrothermal liquefaction of woody biomass. Renewable Energy, 2021, 176: 543–554

Lu Q, Guo H, Zhou M, et al. Monocyclic aromatic hydrocarbons production from catalytic cracking of pine wood-derived pyrolytic vapors over Ce-Mo2N/HZSM-5 catalyst. Science of the Total Environment, 2018, 634: 141–149

Lalsare A D, Leonard B, Robinson B, et al. Self-regenerable carbon nanofiber supported Fe-Mo2C catalyst for CH4-CO2 assisted reforming of biomass to hydrogen rich syngas. Applied Catalysis B: Environmental, 2021, 282: 119537

Hu Q, Shen Y, Chew J W, et al. Chemical looping gasification of biomass with Fe2O3/CaO as the oxygen carrier for hydrogenenriched syngas production. Chemical Engineering Journal, 2020, 379: 122346

Wan Z, Sun Y, Tsang D C W, et al. Sustainable remediation with an electroactive biochar system: Mechanisms and perspectives. Green Chemistry, 2020, 22(9): 2688–2711

Pierri L, Gemenetzi A, Mavrogiorgou A, et al. Biochar as supporting material for heterogeneous Mn(II) catalysts: Efficient olefins epoxidation with H2O2. Molecular Catalysis, 2020, 489: 110946

Molnár Á, Papp A. Catalyst recycling—A survey of recent progress and current status. Coordination Chemistry Reviews, 2017, 349: 1–65

Nikkhah H, Tavasoli A, Jafarian S. Investigating the influence of acid washing pretreatment and Zn/activated biochar catalyst on thermal conversion of Cladophora glomerata to value-added bio-products. Energy Conversion and Management, 2020, 225: 113392

Santos J L, Megías-Sayago C, Ivanova S, et al. Functionalized biochars as supports for Pd/C catalysts for efficient hydrogen production from formic acid. Applied Catalysis B: Environmental, 2021, 282: 119615

Cao L, Yu I K M, Tsang D C W, et al. Phosphoric acid-activated wood biochar for catalytic conversion of starch-rich food waste into glucose and 5-hydroxymethylfurfural. Bioresource Technology, 2018, 267: 242–248

Xiong X, Yu I K M, Chen S S, et al. Sulfonated biochar as acid catalyst for sugar hydrolysis and dehydration. Catalysis Today, 2018, 314: 52–61

Cao L, Yu I K M, Chen S S, et al. Production of 5-hydroxymethylfurfural from starch-rich food waste catalyzed by sulfonated biochar. Bioresource Technology, 2018, 252: 76–82

Behera B, Selvam S M, Dey B, et al. Algal biodiesel production with engineered biochar as a heterogeneous solid acid catalyst. Bioresource Technology, 2020, 310: 123392

Xie Q, Yang X, Xu K, et al. Conversion of biochar to sulfonated solid acid catalysts for spiramycin hydrolysis: Insights into the sulfonation process. Environmental Research, 2020, 188: 109887

Kumar A, Kumar J, Bhaskar T. High surface area biochar from Sargassum tenerrimum as potential catalyst support for selective phenol hydrogenation. Environmental Research, 2020, 186: 109533

Wang S, Shan R, Wang Y, et al. Synthesis of calcium materials in biochar matrix as a highly stable catalyst for biodiesel production. Renewable Energy, 2019, 130: 41–49

Fan L, Lu X, Li S, et al. Dozens-fold improvement of biochar redox properties by KOH activation. Chemical Engineering Journal, 2022, 429: 132203

Li M, Xu F, Li H, et al. Nitrogen-doped porous carbon materials: Promising catalysts or catalyst supports for heterogeneous hydrogenation and oxidation. Catalysis Science & Technology, 2016, 6(11): 3670–3693

Wang X, Liu Y, Zhu L et al. Biomass derived N-doped biochar as efficient catalyst supports for CO2 methanation. Journal of CO2 Utilization, 2019, 34: 733–741

Avhad M, Flaud V, Burel L, et al. Porous carbon as catalyst support for CO oxidation: Impact of nitrogen doping. Carbon, 2020, 169: 297–306

Chen, Y, Ma L, Chen C, et al. Fe and N co-doped carbon with High doping content of sulfur and nitrogen for efficient CO2 electro-reduction. Journal of CO2 Utilization, 2020, 42: 101316

Shi Z, Yang W, Gu Y, et al. Metal-nitrogen-doped carbon materials as highly efficient catalysts: Progress and rational design. Advanced Science (Weinheim, Baden-Wurttemberg, Germany), 2020, 7(15): 2001069

Sekhon S S, Kaur P, Park J S. From coconut shell biomass to oxygen reduction reaction catalyst: Tuning porosity and nitrogen doping. Renewable & Sustainable Energy Reviews, 2021, 147: 111173

Song Y, Chen W, Zhao C, et al. Metal-free nitrogen-doped mesoporous carbon for electroreduction of CO2 to ethanol. Angewandte Chemie International Edition, 2017, 56(36): 10840–10844

Chen W, Fang Y, Li K, et al. Bamboo wastes catalytic pyrolysis with N-doped biochar catalyst for phenols products. Applied Energy, 2020, 260: 114242

Wang J, Yu X, Shi C, et al. Iron and nitrogen co-doped mesoporous carbon-based heterogeneous catalysts for selective reduction of nitroarenes. Advanced Synthesis & Catalysis, 2019, 361(15): 3525–3531

Cao P, Zhang H Y, Yin G, et al. Nitrogen doped carbon supported iron catalysts for highly selective production of 4,4′-diamino-2,2′-stilbenedisulfonic acid. Catalysis Communications, 2019, 132: 105822

Kim M, Xin R, Earnshaw J, et al. MOF-derived nanoporous carbons with diverse tunable nanoarchitectures. Nature Protocols, 2022, 17(12): 2990–3027

Knothe G, Razon L F. Biodiesel fuels. Progress in Energy and Combustion Science, 2017, 58: 36–59

Huang Z, Zhu L, Li A, et al. Renewable synthetic fuel: Turning carbon dioxide back into fuel. Frontiers in Energy, 2022, 16(2): 145–149

Quah R V, Tan Y H, Mubarak N M, et al. Magnetic biochar derived from waste palm kernel shell for biodiesel production via sulfonation. Waste Management (New York, N.Y.), 2020, 118: 626–636

Lim S, Yap C Y, Pang Y L, et al. Biodiesel synthesis from oil palm empty fruit bunch biochar derived heterogeneous solid catalyst using 4-benzenediazonium sulfonate. Journal of Hazardous Materials, 2020, 390: 121532

Guedes R E, Luna A S, Torres A R. Operating parameter for bio-oil production in biomass pyrolysis: A review. Journal of Analytical and Applied Pyrolysis, 2018, 129: 134–149

Jeong K H, Choi D H, Lee D J, et al. CO2-looping in pyrolysis of horse manure using CaCO3. Journal of Cleaner Production, 2018, 174: 616–624

Yoon K, Jung J M, Cho D W, et al. Engineered biochar composite fabricated from red mud and lipid waste and synthesis of biodiesel using the composite. Journal of Hazardous Materials, 2019, 366: 293–300

Jung J M, Lee S R, Lee J, et al. Biodiesel synthesis using chicken manure biochar and waste cooking oil. Bioresource Technology, 2017, 244: 810–815

Jung S, Kim M, Jung J M, et al. Valorization of swine manure biochar as a catalyst for transesterifying waste cooking oil into biodiesel. Environmental Pollution, 2020, 266: 115377

Foroutan R, Mohammadi R, Razeghi J, et al. Biodiesel production from edible oils using algal biochar/CaO/K2CO3 as a heterogeneous and recyclable catalyst. Renewable Energy, 2021, 168: 1207–1216

Borah M J, Devi A, Borah R, et al. Synthesis and application of Co doped ZnO as heterogeneous nanocatalyst for biodiesel production from non-edible oil. Renewable Energy, 2019, 133: 512–519

Kataria J, Mohapatra S K, Kundu K. Biodiesel production from waste cooking oil using heterogeneous catalysts and its operational characteristics on variable compression ratio CI engine. Journal of the Energy Institute, 2019, 92(2): 275–287

Rabie A M, Shaban M, Abukhadra M R, et al. Diatomite supported by CaO/MgO nanocomposite as heterogeneous catalyst for biodiesel production from waste cooking oil. Journal of Molecular Liquids, 2019, 279: 224–231

Verma S, Nasir Baig R B, Nadagouda M N, et al. Visible light mediated upgrading of biomass to biofuel. Green Chemistry, 2016, 18(5): 1327–1331

Gavahian M, Munekata P E S, Eş I, et al. Emerging techniques in bioethanol production: From distillation to waste valorization. Green Chemistry, 2019, 21(6): 1171–1185

Wu P, Kang X, Wang W, et al. Assessment of coproduction of ethanol and methane from Pennisetum purpureum: Effects of pretreatment, process performance, and mass balance. ACS Sustainable Chemistry & Engineering, 2021, 9(32): 10771–10784

Djioleu A, Carrier D J. Effects of dilute acid pretreatment parameters on sugar production during biochemical conversion of switchgrass using a full factorial design. ACS Sustainable Chemistry & Engineering, 2016, 4(8): 4124–4130

Beig B, Riaz M, Raza Naqvi S, et al. Current challenges and innovative developments in pretreatment of lignocellulosic residues for biofuel production: A review. Fuel, 2021, 287: 119670

Sun X, Atiyeh H K, Kumar A, et al. Biochar enhanced ethanol and butanol production by Clostridium carboxidivorans from syngas. Bioresource Technology, 2018, 265: 128–138

Sun X, Atiyeh H K, Kumar A, et al. Enhanced ethanol production by Clostridium ragsdalei from syngas by incorporating biochar in the fermentation medium. Bioresource Technology, 2018, 247: 291–301

Kyriakou M, Chatziiona V K, Costa C N, et al. Biowaste-based biochar: A new strategy for fermentative bioethanol overproduction via whole-cell immobilization. Applied Energy, 2019, 242: 480–491

Xiao L, Lichtfouse E, Kumar P S, et al. Biochar promotes methane production during anaerobic digestion of organic waste. Environmental Chemistry Letters, 2021, 19(5): 3557–3564

Yuan H Y, Ding L J, Zama E F, et al. Biochar modulates methanogenesis through electron syntrophy of microorganisms with ethanol as a substrate. Environmental Science & Technology, 2018, 52(21): 12198–12207

Xiao L, Liu F, Liu J, et al. Nano-Fe3O4 particles accelerating electromethanogenesis on an hour-long timescale in wetland soil. Environmental Science. Nano, 2018, 5(2): 436–445

Li L, Fu C, Shen S, et al. Influence of Fe on electrocatalytic activity of iron-nitrogen-doped carbon materials toward oxygen reduction reaction. Frontiers in Energy, 2022, 16(5): 812–821

Qin Y, Yin X, Xu X, et al. Specific surface area and electron donating capacity determine biochar’s role in methane production during anaerobic digestion. Bioresource Technology, 2020, 303: 122919

Paranhos A G O, Adarme O F H, Barreto G F, et al. Methane production by co-digestion of poultry manure and lignocellulosic biomass: Kinetic and energy assessment. Bioresource Technology, 2020, 300: 122588

Xu S, Wang C, Duan Y, et al. Impact of pyrochar and hydrochar derived from digestate on the co-digestion of sewage sludge and swine manure. Bioresource Technology, 2020, 314: 123730

Yang H J, Yang Z M, Xu X H, et al. Increasing the methane production rate of hydrogenotrophic methanogens using biochar as a biocarrier. Bioresource Technology, 2020, 302: 122829

Li L, Yan K, Chen J, et al. Fe-rich biomass derived char for microwave-assisted methane reforming with carbon dioxide. Science of the Total Environment, 2019, 657: 1357–1367

He T, Pachfule P, Wu H, et al. Hydrogen carriers. Nature Reviews. Materials, 2016, 1: 16059

Ji S, Lai C, Zhou H, et al. In situ growth of NiSe2 nanocrystalline array on graphene for efficient hydrogen evolution reaction. Frontiers in Energy, 2022, 16(4): 595–600

Zhang P, Guo Y J, Chen J, et al. Streamlined hydrogen production from biomass. Nature Catalysis, 2018, 1(5): 332–338

Shangguan W, Kudo A, Jiang Z, et al. Photocatalysis: From solar light to hydrogen energy. Frontiers in Energy, 2021, 15(3): 565–567

Navlani-García M, Salinas-Torres D, Mori K, et al. Enhanced formic acid dehydrogenation by the synergistic alloying effect of PdCo catalysts supported on graphitic carbon nitride. International Journal of Hydrogen Energy, 2019, 44(53): 28483–28493

Han T, Yang W, Jönsson P G. Pyrolysis and subsequent steam gasification of metal dry impregnated lignin for the production of H2-rich syngas and magnetic activated carbon. Chemical Engineering Journal, 2020, 394: 124902

Weber K, Quicker P. Properties of biochar. Fuel, 2018, 217: 240–261

Tran T K, Kim N, Leu H J, et al. The production of hydrogen gas from modified water hyacinth (Eichhornia Crassipes) biomass through pyrolysis process. International Journal of Hydrogen Energy, 2021, 46(27): 13976–13984

Yao D, Hu Q, Wang D, et al. Hydrogen production from biomass gasification using biochar as a catalyst/support. Bioresource Technology, 2016, 216: 159–164

Ibrahim A F M, Dandamudi K P R, Deng S, et al. Pyrolysis of hydrothermal liquefaction algal biochar for hydrogen production in a membrane reactor. Fuel, 2020, 265: 116935

Sunyoto N M S, Zhu M, Zhang Z, et al. Effect of biochar addition on hydrogen and methane production in two-phase anaerobic digestion of aqueous carbohydrates food waste. Bioresource Technology, 2016, 219: 29–36

Bu J, Wei H L, Wang Y T, et al. Biochar boosts dark fermentative H2 production from sugarcane bagasse by selective enrichment/colonization of functional bacteria and enhancing extracellular electron transfer. Water Research, 2021, 202: 117440

Li W, Cheng C, He L, et al. Effects of feedstock and pyrolysis temperature of biochar on promoting hydrogen production of ethanol-type fermentation. Science of the Total Environment, 2021, 790: 148206

Effendi A, Gerhauser H, Bridgwater A V. Production of renewable phenolic resins by thermochemical conversion of biomass: A review. Renewable & Sustainable Energy Reviews, 2008, 12(8): 2092–2116

Chen W, Li K, Xia M, et al. Catalytic deoxygenation copyrolysis of bamboo wastes and microalgae with biochar catalyst. Energy, 2018, 157: 472–482

Wang C, Lei H, Zhao Y, et al. Integrated harvest of phenolic monomers and hydrogen through catalytic pyrolysis of biomass over nanocellulose derived biochar catalyst. Bioresource Technology, 2021, 320: 124352

Gurrala L, Kumar M M, Yerrayya A, et al. Unraveling the reaction mechanism of selective C9 monomeric phenol formation from lignin using Pd-Al2O3-activated biochar catalyst. Bioresource Technology, 2022, 344(Part B): 126204

Liu Y, He P, Shao L, et al. Significant enhancement by biochar of caproate production via chain elongation. Water Research, 2017, 119: 150–159

Ghysels S, Buffel S, Rabaey K, et al. Biochar and activated carbon enhance ethanol conversion and selectivity to caproic acid by Clostridium kluyveri. Bioresource Technology, 2021, 319: 124236

Saynik P B, Moholkar V S. Investigations in influence of different pretreatments on A donax pyrolysis: Trends in product yield, distribution and chemical composition. Journal of Analytical and Applied Pyrolysis, 2021, 158: 105276

Zheng A, Zhao K, Li L, et al. Quantitative comparison of different chemical pretreatment methods on chemical structure and pyrolysis characteristics of corncobs. Journal of the Energy Institute, 2018, 91(5): 676–682

Lee Y, Kim Y T, Kwon E E, et al. Biochar as a catalytic material for the production of 1,4-butanediol and tetrahydrofuran from furan. Environmental Research, 2020, 184: 109325

Lee Y, Lee S W, Tsang Y F, et al. Engineered rice-straw biochar catalysts for the production of value-added chemicals from furan. Chemical Engineering Journal, 2020, 387: 124194

Khemthong P, Yimsukanan C, Narkkun T, et al. Advances in catalytic production of value-added biochemicals and biofuels via furfural platform derived lignocellulosic biomass. Biomass and Bioenergy, 2021, 148: 106033

Mariscal R, Maireles-Torres P, Ojeda M, et al. Furfural: A renewable and versatile platform molecule for the synthesis of chemicals and fuels. Energy & Environmental Science, 2016, 9(4): 1144–1189

Xu C, Paone E, Rodriguez-Padron D, et al. Recent catalytic routes for the preparation and the upgrading of biomass derived furfural and 5-hydroxymethylfurfural. Chemical Society Reviews, 2020, 49(13): 4273–4306

Li X, Lu X, Liang M, et al. Conversion of waste lignocellulose to furfural using sulfonated carbon microspheres as catalyst. Waste Management (New York, N.Y.), 2020, 108: 119–126

Guo T, Li X, Liu X, et al. Catalytic transformation of lignocellulosic biomass into arenes, 5-hydroxymethylfurfural, and furfural. ChemSusChem, 2018, 11(16): 2758–2765

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52100185), the Natural Science Foundation of Hunan Province (Grant No. 2021JJ40282), the Training Program for Excellent Young Innovators of Changsha (kq2106087 and kq2106088), the Science and Technology Innovation Program of Hunan Province (2021RC2100, 2021SK2040, and 2019SK2191), and the National Key R&D Program of China (No. 2018YFC1901203).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Li, H., Hou, C., Zhai, Y. et al. Selective preparation for biofuels and high value chemicals based on biochar catalysts. Front. Energy 17, 635–653 (2023). https://doi.org/10.1007/s11708-023-0878-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-023-0878-4