Abstract

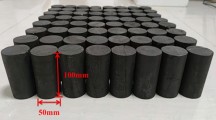

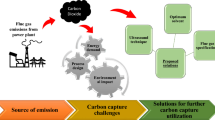

A one-dimensional transient single coal particle combustion model was proposed to investigate the characteristics of single coal particle combustion in both O2/N2 and O2/CO2 atmospheres under the fluidized bed combustion condition. The model accounted for the fuel devolatilization, moisture evaporation, heterogeneous reaction as well as homogeneous reactions integrated with the heat and mass transfer from the fluidized bed environment to the coal particle. This model was validated by comparing the model prediction with the experimental results in the literature, and a satisfactory agreement between modeling and experiments proved the reliability of the model. The modeling results demonstrated that the carbon conversion rate of a single coal particle (diameter 6 to 8 mm) under fluidized bed conditions (bed temperature 1088 K) in an O2/CO2 (30:70) atmosphere was promoted by the gasification reaction, which was considerably greater than that in the O2/N2 (30:70) atmosphere. In addition, the surface and center temperatures of the particle evolved similarly, no matter it is under the O2/N2 condition or the O2/CO2 condition. A further analysis indicated that similar trends of the temperature evolution under different atmospheres were caused by the fact that the strong heat transfer under the fluidized bed condition overwhelmingly dominated the temperature evolution rather than the heat release of the chemical reaction.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area/m2

- c i :

-

Mass concentration of species i/(kg · m−3)

- c p :

-

Heat capacity at constant pressure/(J · (kg · K)−1)

- C :

-

Amount of carbon in the coal/%

- D :

-

Gas diffusion coefficient/(m2 · s−1)

- h :

-

Overall heat transfer coefficient between particle and atmosphere/(W · (m2 · K)1)

- h g :

-

Heat transfer coefficient between reaction sheet and atmosphere/(W · (m2 · K)−1)

- h in :

-

Heat transfer coefficient between particle and reaction sheet/(W · (m2 · K)−1)

- H :

-

Amount of hydrogen in the coal/%

- k pyro :

-

Rate constant of devolatilization/(kg · s−1)

- k vap :

-

Rate constant of vaporization/(kg · s−1)

- L 0 :

-

Initial pore length/m

- MW c :

-

Carbon molecular weight/(kg · mol−1)

- m :

-

Mass/kg

- m v :

-

Mass of volatiles/kg

- N :

-

Amount of nitrogen in the coal/%

- Nu:

-

Nusselt number (-)

- O :

-

Amount of oxygen in the coal/%

- Pr:

-

Prandtl number (-)

- Q r :

-

Heat release rate of heterogeneous reaction/(J · s−1)

- Q h :

-

Heat transfer between the fuel particle and environment/(J · s−1)

- Q*:

-

Non-dimensional heat ratio (-)

- Re:

-

Reynolds number (-)

- R u :

-

Universal gas constant

- r :

-

Radius/m

- r ef :

-

Radius of evaporation layer/(m · s−1)

- S :

-

Amount of sulfur in the coal/%

- S r :

-

Source term/(kg · (m3 · s)−1 or W · (m3 · s)−1)

- Sc:

-

Schmidt number (-)

- Sh:

-

Sherwood number (-)

- s :

-

Volume-specific surface area/m−1

- T :

-

Temperature/K

- t :

-

Time/s

- U g :

-

Fluidization velocity/(m · s−1)

- U mf :

-

Minimum fluidization velocity/(m · s−1)

- V :

-

Particle volume/m3

- v :

-

Gas viscosity/(m2 · s−1)

- v i,j :

-

Stoichiometric coefficients of species i in reaction j (-)

- w h,j :

-

Rate of j homogeneous reaction/(103mol ·(m3 · s)−1)

- w s,j :

-

Rate of j heterogeneous reaction (103mol · (m3 · s)−1)

- X c :

-

Carbon conversion rate (-)

- ΔH h,j :

-

Reaction heat of j omogeneous reaction/(J · (kmol)−1

- ΔH sj :

-

Reaction heat of j heterogeneous reaction/(J ·(kmol)−1)

- ΔH vap :

-

Vaporization heat/(J · kg−1)

- φ A :

-

Mass fraction of ash (-)

- φ C :

-

Mass fraction of carbon (-)

- φ M :

-

Mass fraction of moisture (-)

- φ V :

-

Mass fraction of volatiles (-)

- ΔM :

-

Consumption rate of char/(kg · s−1)

- [i]:

-

Mole concentration of species i/(mol · m−3)

- α i :

-

Stoichiometric coefficient of species i in the devolatilization reaction (-)

- β g :

-

Mass transfer coefficient between reaction sheet and atmosphere/(m · s−1)

- βin :

-

Mass transfer coefficient between particle and reaction sheet/(m · s−1)

- ε :

-

Emissivity (-)

- ε mf :

-

Bed voidage at the minimum fluidization state (-)

- ε 0 :

-

Porosity of char (-)

- λ :

-

Thermal conductivity/(W · (m · K)−1)

- μ :

-

Dynamic viscosity/(N · s · m−2)

- ρ :

-

Mass density/(kg · m−3)

- σ :

-

Stefan-Boltzmann constant/(W · (m2 · K4)−1)

- ψ :

-

Structural parameter of the char (-)

- Δt :

-

Time-step/s

- par:

-

Particle

- rs:

-

The reaction sheet

- b:

-

Fluidized bed

- ps:

-

Particle surface

- ∞:

-

Infinity far boundary

- 0:

-

Initial state

References

Wang H, He J. China’s pre-2020 CO2 emission reduction potential and its influence. Frontiers in Energy, 2019, 13(3): 571–578

Wang W, Li Z, Lyu J, Zhang H, Yue G, Ni W. An overview of the development history and technical progress of China’s coal-fired power industry. Frontiers in Energy, 2019, 13(3): 417–426

Kanniche M, Gros-Bonnivard R, Jaud P, Valle-Marcos J, Amann J M, Bouallou C. Pre-combustion, post-combustion and oxy-combustion in thermal power plant for CO2 capture. Applied Thermal Engineering, 2010, 30(1): 53–62

Kunze C, Spliethoff H. Assessment of oxy-fuel, pre- and post-combustion-based carbon capture for future IGCC plants. Applied Energy, 2012, 94: 109–116

Leung D Y C, Caramanna G, Maroto-Valer M M. An overview of current status of carbon dioxide capture and storage technologies. Renewable & Sustainable Energy Reviews, 2014, 39: 426–443

Kazanc F, Khatami R, Manoel Crnkovic P, Levendis Y A. Emissions of NOx and SO2 from coals of various ranks, bagasse, and coal-bagasse blends burning in O2/N2 and O2/CO2 environments. Energy & Fuels, 2011, 25(7): 2850–2861

Khatami R, Stivers C, Joshi K, Levendis Y A, Sarofim A F. Combustion behavior of single particles from three different coal ranks and from sugar cane bagasse in O2/N2 and O2/CO2 atmospheres. Combustion and Flame, 2012, 159(3): 1253–1271

Khatami R, Stivers C, Levendis Y A. Ignition characteristics of single coal particles from three different ranks in O2/N2 and O2/CO2 atmospheres. Combustion and Flame, 2012, 159(12): 3554–3568

Riaza J, Khatami R, Levendis Y A, Álvarez L, Gil M V, Pevida C, Rubiera F, Pis J J. Single particle ignition and combustion of anthracite, semi-anthracite and bituminous coals in air and simulated oxy-fuel conditions. Combustion and Flame, 2014, 161(4): 1096–1108

Piotrowska P, Zevenhoven M, Davidsson K, Hupa M, Åmand L E, Barišić V, Coda Zabetta E. Fate of alkali metals and phosphorus of rapeseed cake in circulating fluidized bed boiler. Part 2: cocombustion with coal. Energy & Fuels, 2010, 24(8): 4193–4205

Piotrowska P, Zevenhoven M, Davidsson K, Hupa M, Åmand L E, Barišić V, Coda Zabetta E. Fate of alkali metals and phosphorus of rapeseed cake in circulating fluidized bed boiler. Part 1: cocombustion with wood. Energy & Fuels, 2010, 24(1): 333–345

Leckner B, Gómez-Barea A. Oxy-fuel combustion in circulating fluidized bed boilers. Applied Energy, 2014, 125: 308–318

Seddighi K S, Pallarès D, Normann F, Johnsson F. Progress of combustion in an oxy-fuel circulating fluidized-bed furnace: measurements and modeling in a 4 MWth boiler. Energy & Fuels, 2013, 27(10): 6222–6230

Tan Y, Jia L, Wu Y, Anthony E J. Experiences and results on a 0.8 MWth oxy-fuel operation pilot-scale circulating fluidized bed. Applied Energy, 2012, 92: 343–347

Duan L, Sun H, Zhao C, Zhou W, Chen X. Coal combustion characteristics on an oxy-fuel circulating fluidized bed combustor with warm flue gas recycle. Fuel, 2014, 127: 47–51

Varol M, Symonds R, Anthony E J, Lu D, Jia L, Tan Y. Emissions from co-firing lignite and biomass in an oxy-fired CFBC. Fuel Processing Technology, 2018, 173: 126–133

Hernberg R, Stenberg J, Zethraus B. Simultaneous in situ measurement of temperature and size of burning char particles in a fluidized bed furnace by means of fiberoptic pyrometry. Combustion and Flame, 1993, 95(1–2): 191–205

Joutsenoja T, Heino P, Hernberg R, Bonn B. Pyrometric temperature and size measurements of burning coal particles in a fluidized bed combustion reactor. Combustion and Flame, 1999, 118(4): 707–717

Bu C, Leckner B, Chen X, Pallarès D, Liu D, Gómez-Barea A. Devolatilization of a single fuel particle in a fluidized bed under oxy-combustion conditions. Part A: experimental results. Combustion and Flame, 2015, 162(3): 797–808

Lupion M, Alvarez I, Otero P, Kuivalainen R, Lantto J, Hotta A, Hack H. 30 MWth CIUDEN oxy-cfb boiler-first experiences. Energy Procedia, 2013, 37: 6179–6188

Lyu J, Yang H, Ling W, Nie L, Yue G, Li R, Chen Y, Wang S. Development of a supercritical and an ultra-supercritical circulating fluidized bed boiler. Frontiers in Energy, 2019, 13(1): 114–119

Garcia-Gutierrez L, Hernández-Jiménez F, Cano-Pleite E, Soria-Verdugo A. Improvement of the simulation of fuel particles motion in a fluidized bed by considering wall friction. Chemical Engineering Journal, 2017, 321: 175–183

Zhu S, Zhang M, Huang Y, Wu Y, Yang H, Lyu J, Gao X, Wang F, Yue G. Thermodynamic analysis of a 660 MW ultra-supercritical CFB boiler unit. Energy, 2019, 173: 352–363

Saxena S C. Devolatilization and combustion characteristics of coal particles. Progress in Energy and Combustion Science, 1990, 16(1): 55–94

Solomon P R, Serio M A, Suuberg E M. Coal pyrolysis: experiments, kinetic rates and mechanisms. Progress in Energy and Combustion Science, 1992, 18(2): 133–220

Chern J S, Hayhurst A N. Does a large coal particle in a hot fluidised bed lose its volatile content according to the shrinking core model? Combustion and Flame, 2004, 139(3): 208–221

Scala F, Chirone R. Fluidized bed combustion of single coal char particles at high CO2 concentration. Chemical Engineering Journal, 2010, 165(3): 902–906

Scala F, Chirone R. Combustion of single coal char particles under fluidized bed oxyfiring conditions. Industrial & Engineering Chemistry Research, 2010, 49(21): 11029–11036

Guedea I, Pallarès D, Díez L I, Johnsson F. Conversion of large coal particles under O2/N2 and O2/CO2 atmospheres—experiments and modeling. Fuel Processing Technology, 2013, 112: 118–128

Bu C, Leckner B, Chen X, Gómez-Barea A, Liu D, Pallarès D. Devolatilization of a single fuel particle in a fluidized bed under oxy-combustion conditions. Part B: modeling and comparison with measurements. Combustion and Flame, 2015, 162(3): 809–818

Salinero J, Gómez-Barea A, Fuentes-Cano D, Leckner B. Measurement and theoretical prediction of char temperature oscillation during fluidized bed combustion. Combustion and Flame, 2018, 192:190–204

Nikrityuk P, Meyer B. Gasification Processes: Modeling and Simulation. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2014

Bhatia S, Perlmutter D. A random pore model for fluid-solid reactions: I. Isothermal, kinetic control. AIChE Journal, 1980, 26(3): 379–386

Chern J S, Hayhurst A N. A model for the devolatilization of a coal particle sufficientlylarge to be controlled by heat transfer. Combustion and Flame, 2006, 146(3): 553–571

Loison R, Chauvin F. Rapid coal pyrolysis. Chemical Industry (Paris), 1964, 91 (in French)

Rowe P N, Clayton K T, Lewis J B. Heat mass transfer from single sphere in an extensive flowing fluid. Transactions of the Institution of Chemical Engineers, 1965, 43: 14–31

Herrin J M, Deming D. Thermal conductivity of US coals. Journal of Geophysical Research-Solid Earth, 1996, 101(B11): 25381–25386

Maloney D J, Monazam E R, Woodruff S D, Lawson L O. Measurements and analysis of temperature histories and size changes for single carbon and coal particles during the early stages of heating and devolatilization. Combustion and Flame, 1991, 84(1–2): 210–220

Duan L, Li L, Liu D, Zhao C. Fundamental study on fuel-staged oxy-fuel fluidized bed combustion. Combustion and Flame, 2019, 206: 227–238

Acknowledgements

This work was supported by the National Key R&D Program of China (No. 2018YFF0216002) and the Seed Fund of Shanxi Research Institute for Clean Energy, Tsinghua University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Zhang, Y., Liu, D. et al. Modeling of single coal particle combustion in O2/N2 and O2/CO2 atmospheres under fluidized bed condition. Front. Energy 15, 99–111 (2021). https://doi.org/10.1007/s11708-020-0685-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-020-0685-0