Abstract

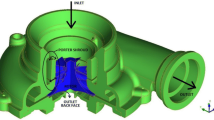

The design of two-stage pusher centrifuges have developed rapidly, but a good understanding of the theory behind their practice is a long-standing problem. To better understand centrifugal filter processes, the computational fluid dynamics (CFD) software program FLUENT has been used to model the three-dimensional geometry and to simulate multiphase flows based on Euler-Euler, moving mesh, dynamic mesh and porous media models. The simulation tangential velocities were a little smaller than those for rigid-body motion. In the stable flow region, the radial velocities were in good agreement with the theoretical data. Additionally, solid concentration distribution were obtained and also showed good agreement with the experimental data. These results show that this simulation method could be an effective tool to optimize the design of the two-stage pusher centrifuge.

Similar content being viewed by others

References

Sandro S. Innovating the pusher centrifuge for bulk chemical separation. Filtration and Separation Technologies, 2003, 40(6): 38–39

Anlauf H. Recent developments in centrifuge technology. Separation and Purification Technology, 2007, 58(2): 242–246

Zhang J. New-fashioned two-stage pusher centrifuge and its application. Chinese Well and Rock Salt, 1994, 21(3): 31–32 (in Chinese)

Yan F, Farouk B. Numerical simulations of flows inside a partially filled centrifuge. Journal of Fluids Engineering, 2003, 125(6): 1033–1042

Zhao C, Yang D, Zhang C. Numerical simulation of liquid-solid two-phase flow in tubular bowl centrifuge. Journal of Filtration & Spearation, 2007, 14(1): 22–25 (in Chinese)

Romaní Fernández X, Nirschl H. Multiphase CFD simulation of a solid bowl centrifuge. Chemical Engineering & Technology, 2009, 32(5): 719–725

Jain M, Paranandi M, Roush D, Göklen K, Kelly WJ. Using CFD to understand how flow patterns affect retention of cell-sized particles in a tubular bowl centrifuge. Industrial & Engineering Chemistry Research, 2005, 44(20): 7876–7884

Deshmukh S S, Joshi J B, Koganti S B. Flow visualization and three-dimensional CFD simulation of the annular region of an annular centrifuge extrator. Industrial & Engineering Chemistry Research, 2008, 47(10): 3677–3686

Janoske U, Piesche M. Numerical simulation of the fluid flow and the separation behavior in a single gap of a disk stack centrifuge. Chemical Engineering & Technology, 1999, 22(3): 213–216

Fluent 6.3 User’s Guide. USA: Ansys Inc., 2006, 730–737

Yakhot V, Smith L. Renormalization-group analysis of turbulence. Annual Review of Fluid Mechanics, 1998, 30(10): 275–310

Zhang M L, Shen Y M. Three-dimensional simulation of meandering river based on 3-D RNG κ-epsilon turbulence model. Journal of Hydrodynamics, 2008, 20(4): 448–455

Kim M, Prost R, Chung H. A blind watermarking for 3-D dynamic mesh model using distribution of temporal wavelet coefficients. MRCS 2006, LNCS 4105: 257–264

Wang Y, Brannock M, Cox S, Leslie G. CFD simulations of membrane filtration zone in a submerged hollow fibre membrane bioreactor using a porous media approach. Journal of Membrane Science, 2010, 363(1–2): 57–66

Sun Q, Jin D. Principle structure and design calculation for centrifuges. China: Machinery Industry, 1984, 223–236 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pang, C., Tan, W., Sha, E. et al. Simulating multiphase flow in a two-stage pusher centrifuge using computational fluid dynamics. Front. Chem. Sci. Eng. 6, 329–338 (2012). https://doi.org/10.1007/s11705-012-1205-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-012-1205-5