Abstract

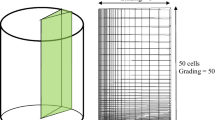

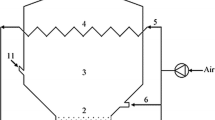

Gasification is one potential way to use sewage sludge as renewable energy and solve the environmental problems caused by the huge amount of sewage sludge. In this paper, a three-dimensional Computational Fluid Dynamics (CFD) model has been developed to simulate the sewage sludge gasification process in a fluidized bed. The model describes the complex physical and chemical phenomena in the gasifier including turbulent flow, heat and mass transfer, and chemical reactions. The model is based on the Eulerian-Lagrangian concept using the nonpremixed combustion modeling approach. In terms of the CFD software FLUENT, which represents a powerful tool for gasifier analysis, the simulations provide detailed information on the gas products and temperature distribution in the gasifier. The model sensitivity is analyzed by performing the model in a laboratory-scale fluidized bed in the literature, and the model validation is carried out by comparing with experimental data from the literature. Results show that reasonably good agreement was achieved. Effects of temperature and Equivalence Ratio (ER) on the quality of product syngas (H2 + CO) are also studied.

Similar content being viewed by others

References

Cui H, Ninomiya Y, Masui M, Mizukoshi H, Sakano T, Kanaoka C. Fundamental Behaviors in Combustion of Raw Sewage Sludge. Energy & Fuels, 2006 20, 77–83

Hartman M, Svoboda K, Pohorely M, Trnka O. Combustion of dried sewage sludge in a fluidized-bed reactor. Ind Eng Chem Res, 2005 44, 3432–3441

Midillia A, Dogrub M, Howarthb C R. Lingc M J, Ayhan T. Combustible gas production from sewage sludge with a downdraft gasifier. Energy Conversion & Management, 2001 42, 157–172

Domi’nguez A, Menéndez J A, Pis J J. Hydrogen rich fuel gas production from the pyrolysis of wet sewage sludge at high temperature. J Anal Appl Pyrolysis, 2006 77, 127–132

Ferrasse J H, Seyssiecq I, Roche N. Thermal Gasification: A Feasible Solution for Sewage Sludge Valorisation?. Chemical Engineering & Technology, 2003 26, 941–945

Manya J, Sanchez J L, Gonzalo A, Arauzo J. Air gasification of dried sewage sludge in a fluidized bed: effect of the operating conditions and in-bed use of alumina. Energy & Fuels, 2005, 19, 629–636

Corella J, Toledo J M. Incineration of doped sludges in fluidized bed. Fate and partitioning of six targeted heavy metals. I. Pilot plant used and results. Journal of Hazardous Materials, 2000 B80, 81–105

Shi S P, Zitney S E, Shahnam M, Syamlal M, Rogers WA. Journal of the Energy Institute, 2006, 79(4): 217–221

Wang S J, Lu J D, Li W J, Hu Z J. Modeling of pulverized coal combustion in cement rotary Kiln. Energy & Fuels, 2006, 20(6): 2350–2356

Chen C X, Horio M, Kojima T. Use of numerical modeling in the design and scale-up of entrained flow coal gasifiers. Fuel, 2001, 80 (10): 1513–1523

Vicente W, Ochoa S, Aguillon J, Barrios E. An Eulerian model for the simulation of an entrained flow coal gasifier. Applied Thermal Engineering, 2003 23(15), 1993–2008

Fletcher D F, Haynes B S, Christo F C, Joseph S D. A CFD based combustion model of an entrained flow biomass gasifier. Applied Mathematical Modelling, 2000 24, 165–182

Grammelis P, Kakaras E. Biomass Combustion Modeling in Fluidized Beds. Energy & Fuels, 2005 19, 292–297

Rostami A A, Hajaligol M R, Wrenn S E. A biomass pyrolysis submodel for CFD applications. Fuel, 2004 83, 1519–155

Petersen I, Werther J. Experimental investigation and modeling of gasification of sewage sludge in the circulating fluidized bed. Chemical Engineering Science, 2005 60(16), 4469–4484

Khiari B, Marias F, Zagrouba F, Vaxelaire J. Use of a transient model to simulate fluidized bed incineration of sewage sludge. Journal of Hazardous Materials, 2006 135(1–3), 200–209

Petersen I, Werther J. Experimental investigation and modeling of gasification of sewage sludge in the circulating fluidized bed. Chemical Engineering and Processing, 2005 44(7), 717–736

Zarnescu V, Pisupati S V. An Integrative Approach for Combustor Design Using CFD Methods. Energy & Fuels, 2002 16, 622–633

Dixon T F, Mann A P, Plaza F, Gilfillan W N. Development of advanced technology for biomass combustion-CFD as an essential tool. Fuel, 2005 84, 1303–1311

Fluent Inc, FLUENT 6.1 User’s Guide. 2003

Sadakaa S S, Ghalyb A E, Sabbahc M A. Two phase bio-mass airsteam gasification model for fluidized bed reactors: Part I-model development. Biomass and Bioenergy, 2002 22, 439–462

Kee R J, Rupley F M, Miller J A. Chemkin-II: A Fortran chemical kinetics package for the analysis of gas-phase chemical kinetics. Technical Report SAND 89-8009, Sandia National Labs, 1989

Filippis P D, Borgianni C, Paolucci M, Pochetti F. Prediction of syngas quality for two-stage gasification of selected waste feedstocks. Waste Management, 2004 24, 633–639

Corella J, Sanz A. Modeling circulating fluidized bed biomass gasifiers:a pseudo-rigorous model for stationary state. Fuel Processing Technology, 2005 86(9), 1021–1053

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Yan, L. CFD based combustion model for sewage sludge gasification in a fluidized bed. Front. Chem. Eng. China 3, 138–145 (2009). https://doi.org/10.1007/s11705-009-0050-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-009-0050-7