Abstract

Utilization of plentiful fine-disseminated iron oxide ores resources attracted increasing attention in these years due to the depletion of easy-dressing iron ore reserves. In this paper, an improved Fe recovery method from the refractory fine-grained iron ores was proposed, and iron can be stepwise recovered by microwave-assisted reduction roasting with the addition of Na2SO4, followed by acid leaching of roasted ore and then magnetic separation of leached ore. Experimental and mechanism analysis results indicated that during the roasting process, 70.38% of Na2SO4 would react with fine-disseminated kaolinite in raw ore to form acid-soluble NaAlSiO4, achieving the crude extraction of ore samples by acid leaching. Moreover, the images of SEM showed that the addition of Na2SO4 during the roasting process can also promote the aggregation and growth of iron-rich particles, promoting the iron-rich particles’ liberation in milling and resulting in a further dramatic improvement in Fe grade and Fe recovery ratio of iron concentrate by magnetic separation. The iron concentrate contained 56.91% Fe, 9.48% Mn, 3.11% Al, and 1.64% Si with a recovery of 83.52%, indeed up to the iron ores quality requirement of the steel and iron industry. This technology can also provide an inspiring idea for utilizing and processing other similar raw materials.

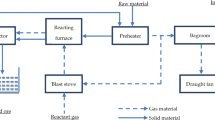

Graphical abstract

Similar content being viewed by others

References

Abreu GC, Carvalho JAd, Silva BECd, Pedrini RH (2015) Operational and environmental assessment on the use of charcoal in iron ore sinter production. J Cleaner Prod 101:387–394

Cavaliere P (2019) Sintering: most efficient technologies for greenhouse emissions abatement. In: Cavaliere P (ed) Clean ironmaking and steelmaking processes: efficient technologies for greenhouse emissions abatement. Springer Internationa Publishing, Cham, pp 111–165

Chen P, Hou P, Zhai J, Sun W (2019) A novel method for the comprehensive utilization of iron and titanium resources from a refractory ore. Sep Purif Technol 226:1–7

Cheng Z, Yang J, Zhou L, Liu Y, Guo Z, Wang Q (2016) Experimental study of commercial charcoal as alternative fuel for coke breeze in iron ore sintering process. Energy Convers Manage 125:254–263

Dong D, Espinoza LAT, Loibl A, Pfaff M, Tukker A, Van der Voet E (2020) Scenarios for anthropogenic copper demand and supply in China: implications of a scrap import ban and a circular economy transition. Resour Conserv Recycl 161:104943

Faris N, Tardio J, Ram R, Bhargava S, Pownceby MI (2017) Investigation into coal-based magnetizing roasting of an iron-rich rare earth ore and the associated mineralogical transformations. Miner Eng 114:37–49

Gualtieri A, Bellotto M (1998) Modelling the structure of the metastable phases in the reaction sequence kaolinite-mullite by X-ray scattering experiments. Phys Chem Miner 25(6):442–452

Jégourel Y (2020) The global iron ore market: From cyclical developments to potential structural changes. Extr Ind Soc 7(3):1128–1134

Jha G, Soren S (2017) Study on applicability of biomass in iron ore sintering process. Renew Sustain Energy Rev 80:399–407

Jiang M, Sun T, Liu Z, Kou J, Liu N, Zhang S (2013) Mechanism of sodium sulfate in promoting selective reduction of nickel laterite ore during reduction roasting process. Int J Miner Process 123:32–38

Kong Z, Dong X, Jiang Q (2019) Forecasting the development of China’s coal-to-liquid industry under security, economic and environmental constraints. Energy Econ 80:253–266

Kumar P, Sahoo BK, De S, Kar DD, Chakraborty S, Meikap BC (2010) Iron ore grindability improvement by microwave pre-treatment. J Ind Eng Chem 16(5):805–812

Li C, Sun H, Bai J, Li L (2010) Innovative methodology for comprehensive utilization of iron ore tailings: Part 1 the recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J Hazard Mater 174(1–3):71–77

Li W, Liu Z, Huang Q, Tang Y, Qiu X (2016) Extraction of low-grade silver from a refractory Au-Ag ore in cyanidation by pretreatment with reductive alkaline leaching. Hydrometallurgy 164:257–264

Liu G, Zheng M, Du B, Nie Z, Zhang B, Liu W, Li C, Hu J (2012) Atmospheric emission of polychlorinated naphthalenes from iron ore sintering processes. Chemosphere 89(4):467–472

Maia AÁB, Angélica RS, de Freitas NR, Pöllmann H, Straub C, Saalwächter K (2014) Use of 29Si and 27Al MAS NMR to study thermal activation of kaolinites from Brazilian Amazon kaolin wastes. Appl Clay Sci 87:189–196

Mao Z, Cheng Y, Liu J, Yuan S, Wu S, Xiang X, Luo X (2013) Geology and molybdenite Re–Os age of the Dahutang granite-related veinlets-disseminated tungsten ore field in the Jiangxin Province, China. Ore Geol Rev 53:422–433

Mizuno N, Kosai S, Yamasue E (2021) Microwave-Based Approach to Recovering Zinc from Electric Arc Furnace Dust Using Silicon Powder as a Non-carbonaceous Reductant. JOM 73(6):1828–1835

Mousa E, Wang C, Riesbeck J, Larsson M (2016) Biomass applications in iron and steel industry: an overview of challenges and opportunities. Renew Sustain Energy Rev 65:1247–1266

Nuri OS, Mehdilo A, Irannajad M (2014) Influence of microwave irradiation on ilmenite surface properties. Appl Surf Sci 311:27–32

Omran M, Fabritius T, Elmahdy AM, Abdel-Khalek NA, El-Aref M, Elmanawi AE-H (2015a) XPS and FTIR spectroscopic study on microwave treated high phosphorus iron ore. Appl Surf Sci 345:127–140

Omran M, Fabritius T, Elmahdy AM, Abdel-Khalek NA, Gornostayev S (2015b) Improvement of phosphorus removal from iron ore using combined microwave pretreatment and ultrasonic treatment. Sep Purif Technol 156:724–737

Omran M, Fabritius T, Mattila R (2015c) Thermally assisted liberation of high phosphorus oolitic iron ore: a comparison between microwave and conventional furnaces. Powder Technol 269:7–14

Ooi TC, Thompson D, Anderson DR, Fisher R, Fray T, Zandi M (2011) The effect of charcoal combustion on iron-ore sintering performance and emission of persistent organic pollutants. Combust Flame 158(5):979–987

Quader MA, Ahmed S, Raja Ghazilla RA, Ahmed S, Dahari M (2016) Evaluation of criteria for CO2 capture and storage in the iron and steel industry using the 2-tuple DEMATEL technique. J Cleaner Prod 120:207–220

Quast K (2018) A review on the characterisation and processing of oolitic iron ores. Miner Eng 126:89–100

Ranzani da Costa A, Wagner D, Patisson F (2013) Modelling a new, low CO2 emissions, hydrogen steelmaking process. J Cleaner Prod 46:27–35

Rao M, Ouyang C, Li G, Zhang S, Zhang Y, Jiang T (2015) Behavior of phosphorus during the carbothermic reduction of phosphorus-rich oolitic hematite ore in the presence of Na2SO4. Int J Miner Process 143:72–79

Roy SK, Nayak D, Rath SS (2020) A review on the enrichment of iron values of low-grade Iron ore resources using reduction roasting-magnetic separation. Powder Technol 367:796–808

Solar J, de Marco I, Caballero BM, Lopez-Urionabarrenechea A, Rodriguez N, Agirre I, Adrados A (2016) Influence of temperature and residence time in the pyrolysis of woody biomass waste in a continuous screw reactor. Biomass Bioenergy 95:416–423

Vassilev SV, Vassileva CG, Vassilev VS (2015) Advantages and disadvantages of composition and properties of biomass in comparison with coal: an overview. Fuel 158:330–350

Wei R, Feng S, Long H, Li J, Yuan Z, Cang D, Xu C (2017a) Coupled biomass (lignin) gasification and iron ore reduction: a novel approach for biomass conversion and application. Energy 140:406–414

Wei R, Zhang L, Cang D, Li J, Li X, Xu CC (2017b) Current status and potential of biomass utilization in ferrous metallurgical industry. Renew Sustain Energy Rev 68:511–524

Wu F, Cao Z, Wang S, Zhong H (2017) Phase transformation of iron in limonite ore by microwave roasting with addition of alkali lignin and its effects on magnetic separation. J Alloys Compd 722:651–661

Ye Q, Li G, Peng Z, Lee J, Lin X, Rao M, Zhang Y, Jiang T (2019) Microwave-assisted self-reduction of composite briquettes of zinc ferrite and carbonaceous materials. Powder Technol 342:224–232

Zhang K, Xl C, Wc G, Hj L, Zj G, Li Bw Wu, Wf, (2017) Effects of biomass reducing agent on magnetic properties and phase transformation of Baotou low-grade limonite during magnetizing-roasting. PLoS ONE 12(10):e0186274

Zhao W, Chen J, Chang X, Guo S, Srinivasakannan C, Chen G, Peng J (2014) Effect of microwave irradiation on selective heating behavior and magnetic separation characteristics of Panzhihua ilmenite. Appl Surf Sci 300:171–177

Acknowledgements

This work was supported by Hunan Province Science and Technology Talent Support Project [Grant number 2022TJ-N15]; Key scientific research project of Education Department of Hunan Province [Grant number 20A245]; General project of Natural Science Foundation of Hunan Province [Grant number 2021JJ30410]; General project of Natural Science Foundation of Hunan Province [Grant number 2022JJ30348]; China postdoctoral science foundation [Grant number 2018M640750].

Funding

Hunan Province Science and Technology Talent Support Project, 2022TJ-N15, Fangfang Wu, Key scientific research project of Education Department of Hunan Province, 20A245, Fangfang Wu, Natural science foundation of Hunan province, 2021JJ30410, Fangfang Wu, Natural Science Foundation of Hunan Province, 2022JJ30348, Fangfang Wu, China postdoctoral science foundation, 2018M640750, Fangfang Wu.

Author information

Authors and Affiliations

Contributions

L Chen: Conceptualization, Methodology, Formal analysis, Writing—review & editing, Funding acquisition; Y He: Investigation, Data curation, Validation, Writing—original draft; J Hu: Investigation, Data curation, Formal analysis; Q Han: Investigation, Data curation; S Gu: Conceptualization, Data curation; P Chen: Conceptualization, Methodology, Supervision; X Fang: Resources, Supervision; F Wu: Resources, Funding acquisition, Methodology, Supervision, Validation.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, L., He, Y., Hu, J. et al. Development of roasting-acid leaching-magnetic separation technology for recovery of iron from “dead ores”. Chem. Pap. 77, 977–986 (2023). https://doi.org/10.1007/s11696-022-02534-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-022-02534-0