Abstract

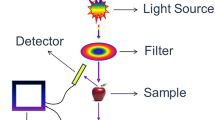

Effective fruit quality inspection and authentication methods and techniques are the essential requirement at various stages of fruit chain cycle (from field to market) to maintain the quality of end products. Several destructive (impedance type, capacitive type etc.) and non-destructive (electronic nose, optical type, ultrasonic based etc.) type techniques and methods have been explored from various researchers for fruit quality measurement and authentication. Most of them uses single sensing technique to extract various quality parameters while as combining two or more complementary sensing techniques will provide better insight about various fruit samples. This manuscript reports four different non-destructive sensing techniques such as electronic nose, UV–Vis–NIR spectroscopy, and ultrasound and machine vision to acquire internal and external attributes of citrus samples. 100 citrus samples have been collected from local market and nearby citrus orchard. Data acquisition process has been performed episodically using developed four independent handheld systems (electronic nose, UV–Vis–NIR spectroscopy, ultrasonic and machine vision). Standard systems such as refractometer, Vernier calipers and weighing machine have been used to generate target predictors such as total soluble solid (%Brix), volume and weight. While as different chemical experiments have been used to generate dataset of chlorophyll and sugar content in the collected citrus samples. Different statistical and ANN based modelling methods have been used to correlate sensory panel response of each developed system separately. Further, various data fusion architectures such as low, mid and high level have been explored to combine the data coming from different implemented sensing techniques. Similar modelling methods have been used to correlate combined dataset of multiple sensing techniques with standard quality parameters. Results obtained with single sensing techniques have been compared with the results generated using multiple sensing technique fusion. Best obtained result for each quality parameter have been used to develop new hybrid data fusion model to predict various fruit quality parameters quantitatively. Predicted quality parameters have been further used to correlate with various important fruit quality decision judgement such as maturity, ripeness and flavor and further predicted quality parameters have been used to judge the optimal harvesting time of on-tree citrus sample.

Similar content being viewed by others

References

S. Khalifa, M. Komarizadeh, B. Tousi, Usage of fruit response to both force and forced vibration applied to assess fruit firmness-a review. Aust. J. Crop Sci. 5(5), 516 (2011)

RJL Systems, home page. https://www.rjlsystems.com/applications-of-bia/real-time-bioelectrical-impedance-analysis-experiment-4-0/. Accessed 6 May 2017

C. Pictiaw, Z. Sun, A review of non-destructive methods for quality evaluation and sorting of agricultural products. J Agric Eng. Res. 49, 85–98 (1991)

H. Gao, F. Zhu, J. Cai: A review of non-destructive detection for fruit quality. International Conference on Computer and Computing Technologies in Agriculture. Springer, Berlin (2009)

C. Li, P. Heinemann, R. Sherry, Neural network and Bayesian network fusion models to fuse electronic nose and surface acoustic wave sensor data for apple defect detection. Sens. Actuat. B 125(1), 301–310 (2007)

W. Wang, J. Paliwal, Near-infrared spectroscopy and imaging in food quality and safety. Sens. Instrum. Food Qual. Saf. 1(4), 193–207 (2007)

S. Cubero et al., Advances in machine vision applications for automatic inspection and quality evaluation of fruits and vegetables. Food Bioprocess Technol. 4(4), 487–504 (2011)

M. Valente, A. Prades, D. Laux, Potential use of physical measurements including ultrasound for a better mango fruit quality characterization. J. Food Eng. 116(1), 57–64 (2013)

Sun, D.-W.: ed. Hyperspectral imaging for food quality analysis and control. Elsevier, (2010)

E. Borràs et al., Data fusion methodologies for food and beverage authentication and quality assessment: a review. Anal. Chim. Acta 891, 1–14 (2015)

J. Brezmes et al., Correlation between electronic nose signals and fruit quality indicators on shelf-life measurements with pinklady apples. Sens. Actuators B 80(1), 41–50 (2001)

A. Sanaeifar et al., Development and application of a new low cost electronic nose for the ripeness monitoring of banana using computational techniques (PCA, LDA, SIMCA and SVM). Czech J. Food Sci. 32(6), 538–548 (2014)

Nordiyana, S. et al.: Development of electronic nose for fruits ripeness determination. (2005)

J.A. Ragazzo-Sanchez et al., Off-flavors detection in alcoholic beverages by electronic nose coupled to GC. Sens. Actuators B 140(1), 29–34 (2009)

A. Zakaria et al., Improved maturity and ripeness classifications of magnifera indica cv. harumanis mangoes through sensor fusion of an electronic nose and acoustic sensor. Sensors 12(5), 6023–6048 (2012)

Z. Haddi et al., E-Nose and e-Tongue combination for improved recognition of fruit juice samples. Food Chem. 150, 246–253 (2014)

C. Di Natale, Corrado, et al., Outer product analysis of electronic nose and visible spectra: application to the measurement of peach fruit characteristics. Anal. Chim. Acta 459(1), 107–117 (2002)

M. Zude et al., Non-destructive tests on the prediction of apple fruit flesh firmness and soluble solids content on tree and in shelf life. J. Food Eng. 77(2), 254–260 (2006)

Seal, D.: ARM architecture reference manual. Ed. Dave Jaggar. Prentice Hall, (1996)

G. Kortüm, Reflectance Spectroscopy: Principles, Methods, Applications (Springer, New York, 2012)

Texas Instruments “Monolithic Photodiode and Single-Supply Transimpedance Amplifier”, OPT 101 datasheet, January, 1994 (2015)

I.S. Bahtiar, P. Andjar, I. Dewa Gede Hari Wisana, Phototherapy radiometer with AS7262 sensor. J Electron. Electromed. Eng. Med. Informat. 1(1), 39–45 (2019)

Moore, H. MATLAB for Engineers. Pearson, 2017.

A. Mizrach, Nondestructive ultrasonic monitoring of tomato quality during shelf-life storage. Postharvest Biol. Technol. 46(3), 271–274 (2007)

E.W. Yemm, A.J. Willis, The estimation of carbohydrates in plant extracts by anthrone. Biochem J 57(3), 508 (1954)

R. Ronen, M. Galun, Pigment extraction from lichens with dimethyl sulfoxide (DMSO) and estimation of chlorophyll degradation. Environ. Exp. Bot. 24(3), 239–245 (1984)

H. Zhang et al., Evaluation of peach quality indices using an electronic nose by MLR, QPST and BP network. Sens. Actuators B 134(1), 332–338 (2008)

H. Zhang, J. Wang, S. Ye, Predictions of acidity, soluble solids and firmness of pear using electronic nose technique. J. Food Eng. 86(3), 370–378 (2008)

H. Zhang et al., Application of electronic nose and statistical analysis to predict quality indices of peach. Food Bioprocess Technol. 5(1), 65–72 (2012)

B.G. Kermani, S.S. Susan, H.T. Nagle, Performance of the Levenberg–Marquardt neural network training method in electronic nose applications. Sens. Actuators B 110(1), 13–22 (2005)

S. De Vito et al., CO, NO2 and NOx urban pollution monitoring with on-field calibrated electronic nose by automatic bayesian regularization. Sens. Actuators B 143(1), 182–191 (2009)

J. Brezmes et al., Evaluation of an electronic nose to assess fruit ripeness.". IEEE Sens. J. 5(1), 97–108 (2005)

S. De Vito et al., On field calibration of an electronic nose for benzene estimation in an urban pollution monitoring scenario. Sens. Actuators B 129(2), 750–757 (2008)

R.V. Chothe, S.P. Ugale, E-Nose for gas detection at vehicle exhaust using supervised learning algorithm. Volume 1, 145–149 (2012)

D. Valero, S. María, Growth and ripening stage at harvest modulates postharvest quality and bioactive compounds with antioxidant activity. Stewart Postharvest Rev. 3(5), 40 (2013)

D.J. Iglesias et al., Physiology of citrus fruiting. Braz. J. Plant Physiol. 19(4), 333–362 (2007)

S. Hardy, G. Sanderson, Citrus maturity testing. Primefact 980, 1–6 (2010)

M. Riaz et al., Quality assessment in different stages of maturity of fruits, mandarins kinnow and feutrell’s early collected from the fruit market of Quetta city at in relation to their benefits for human health. Am. Euras. J. Toxicol. Sci. 7(3), 203–208 (2015)

J.X. Shi et al., Regulatory aspects of ethanol fermentation in immature and mature citrus fruit. J. Am. Soc. Hortic. Sci. 132(1), 126–133 (2007)

V. Steinmetz, F. Sevila, V. Bellon-Maurel, A methodology for sensor fusion design: application to fruit quality assessment. J. Agric. Eng. Res. 74(1), 21–31 (1999)

T. Ignat, V. Alchanatis, Z. Schmilovitch, Maturity prediction of intact bell peppers by sensor fusion. Comput. Electron. Agric. 104, 9–17 (2014)

J.I. Aranda-Sanchez, A. Baltazar, G. González-Aguilar, Implementation of a Bayesian classifier using repeated measurements for discrimination of tomato fruit ripening stages. Biosys. Eng. 102(3), 274–284 (2009)

A. Baltazar, J.I. Aranda, G. González-Aguilar, Bayesian classification of ripening stages of tomato fruit using acoustic impact and colorimeter sensor data. Comput. Electron. Agric. 60(2), 113–121 (2008)

X. Zou, J. Zhao, Apple quality assessment by fusion three sensors." SENSORS, 2005 IEEE. IEEE, (2005)

F. Narváez, J. Yandún et al., LiDAR and thermal images fusion for ground-based 3D characterisation of fruit trees. Biosyst. Eng. 151, 479–494 (2016)

R. Ahmad, Y. Brian, Machine learning based citrus orchard health analysis with autonomous drone technology.

P. Li, S.-H. Lee, H.-Y. Hsu, Review on fruit harvesting method for potential use of automatic fruit harvesting systems. Procedia Eng. 23, 351–366 (2011)

D. Font et al., A proposal for automatic fruit harvesting by combining a low cost stereovision camera and a robotic arm. Sensors 14(7), 11557–11579 (2014)

P. Roy et al., Vision-based preharvest yield mapping for apple orchards. Comput. Electron. Agric. 164, 104897 (2019)

C. Barrows, D.M. Bulanon, Development of a low-cost multispectral camera for aerial crop monitoring. J. Unman. Vehicle Syst. 5(4), 192–200 (2017)

N. Aleixos et al., Multispectral inspection of citrus in real-time using machine vision and digital signal processors. Comput. Electron. Agric. 33(2), 121–137 (2002)

J. Blasco, N. Aleixos, E. Moltó, Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 81(3), 535–543 (2007)

F. López-García et al., Automatic detection of skin defects in citrus fruits using a multivariate image analysis approach. Comput. Electron. Agric. 71(2), 189–197 (2010)

J. Blasco et al., Recognition and classification of external skin damage in citrus fruits using multispectral data and morphological features. Biosyst. Eng. 103(2), 137–145 (2009)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srivastava, S., Sadistap, S. Data fusion for fruit quality authentication: combining non-destructive sensing techniques to predict quality parameters of citrus cultivars. Food Measure 16, 344–365 (2022). https://doi.org/10.1007/s11694-021-01165-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-021-01165-5