Abstract

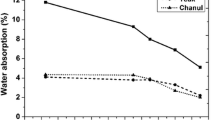

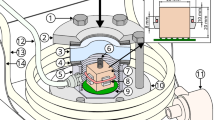

Wood heat treatment has increased significantly in recent years and is still growing as an industrial process to improve some wood properties. We studied the change of swellingand surface roughness of common alder (Alnus glutinosa (L.) Gaertn. ssp.glutinosa) and wych elm (Ulmus glabra Huds.) woods after heat treatment at two different temperatures and durations. The temperatures were 180 and 200 °C and the durations were 2 and 4 h. A stylus method was employed to evaluate the surface characteristics of the samples. Roughness measurements by the stylus method were made in the direction perpendicular to the fiber on the wood surface. Four main roughness parameters, mean arithmetic deviation of profile (R a), mean peak-to-valley height (R z), root mean square roughness (R q), and maximum roughness (R y) were used to evaluate the effect of heat treatment on the surface characteristics of the specimens. Swelling and surface roughness parameters (R a, R z, R y, and R q) differed significantly for two temperatures and two durations of heat treatment. Swelling and surface roughness values decreased with increasing treatment temperature and treatment times.

Similar content being viewed by others

References

Brito JO, Garcia JN, Bortoletto G Jr, Pessoa AMC, Silva PHM (2006) The density and shrinkage behavior of Eucalyptus grandis wood submitted to different temperatures of thermoretification. Cerne Lavras 12(2):182–188

Browicz K, Zielinski J (1982) Ulmus. In: Davis PH et al (eds) Flora of Turkey and the East Aegean Islands, vol VII. Edinburgh University Press, Edinburgh, p 646

Dirol D, Guyonnet R (1993) Durability by rectification process. In: International Research Group Wood Pre. Section 4-Processes, N° IRG/WP 93-40015

Esteves BM, Domingos IJ, Pereira HM (2008) Pine wood modification by heat treatment In air. BioResources 3(1):142–154

Hill CAS (2006) Wood modification: chemical, thermal and other processes. Wiley, Hoboken

Huang X, Kocaefe D, Kocaefe Y, Boluk Y, Pichette A (2012) Changes in wettability of heat-treated wood due to artificial weathering. Wood Sci Technol 46:1215–1237

ISO 3129 (1975) Wood-sampling methods and general requirements for physical and mechanical tests

ISO 4287 (1997) Geometrical product specifications (GPS)-surface texture: profile method-terms. definitions and surface texture parameters. Geneva

ISO 4859 (1982) Wood-determination of radial and tangential swelling

Kalipsiz A 1994. Statistic methods. Istanbul University Publication No. 3835. Faculty of Forestry Publication No. 427. Istanbul University. Istanbul. Turkey. ISBN 975-404-368-X

Mitutoyo Surface Roughness Tester 2002. Mitutoyo Surftest SJ-301. Product no. 99MBB035A1. Series No. 178, Mitutoyo Corporation, 20-1, Sakado 1-chome, Takatsu-ku, Kawasaki, Kanagawa, 213-0012, Japan

Sevim Korkut D, Guller B (2008) The effects of heat treatment on physical properties and surface roughness of red-bud maple (Acer trautvetteri Medw.) wood. Bioresour Technol 99:2846–2851

Stombo DA (1963) Surface texture measurement. For Prod J 13(6):299–304

Tjeerdsma B, Boonstra M, Militz H (1998b) Thermal modification of nondurable wood species, part 2. Improved wood properties of thermally treated wood, International Research Group on Wood Pre., Document no. IRG/WP 98-40124

Tjeerdsma B, Boonstra M, Pizzi A, Tekely P, Militz H (1998) Characterisation of thermaly modified wood: molecular reasons for wood performance improvement. Holz Roh-Werkst 56:149–153

URL 1. http://en.wikipedia.org/wiki/Alnus_glutinosa. Accessed 14 Feb 2013

URL 2. http://en.wikipedia.org/wiki/Ulmus_glabra. Accessed 14 Feb 2013

Yaltirik F, Efe A (2000) Dendrology handbook, Gymnospermae–Angiospermea, University of Istanbul Publication No. 4265, Faculty of Forestry Publication No. 465, ISBN975–404-594-1

Author information

Authors and Affiliations

Corresponding author

Additional information

The online version is available at http://www.springerlink.com

Corresponding editor: Yu Lei

Rights and permissions

About this article

Cite this article

Aytin, A., Korkut, S. Effect of thermal treatment on the swelling and surface roughness of common alder and wych elm wood. J. For. Res. 27, 225–229 (2016). https://doi.org/10.1007/s11676-015-0136-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11676-015-0136-7