Abstract

The process of diffusion mixing at the aluminum-silicon interface in the case of two, four, seven, and ten atomic aluminum monolayers on the silicon (111) surface has been studied. The investigations were performed by the molecular dynamics simulations method using Large-scale Atomic/Molecular Massively Parallel Simulator package. Concentration and density profiles at the phase interface were analyzed to investigate the kinetics of mixing. The formation of a transient diffusion layer at the boundary of the liquid and crystalline phases is established. The melting of the phase interface was explained in the framework of the theory of contact melting. It is shown that diffusion mixing, which precedes contact melting, occurs at the level of atomic blocks (clusters), i.e. we can talk about the island nature of contact melting at the initial stage. The diffusion process was analyzed based on the theory of free volume in liquids.

Similar content being viewed by others

References

C.T. Earnest, J.H. Bejanin, T.G. McConkey, E.A. Peters, A. Korinek, H. Yuan, and M. Mariantoni, Substrate Surface Engineering for High-Quality Silicon/Aluminum Superconducting Resonators, Supercond. Sci. Technol., 2018, 31, p 125013. https://doi.org/10.1088/1361-6668/aae548

A. Megrant, C. Neill, R. Barends et al., Planar Superconducting Resonators with Internal Quality Factors Above One Million, Appl. Phys. Lett., 2012, 100, 113510. https://doi.org/10.1063/1.3693409

C.J.K. Richardson, N.P. Siwak, J. Hackley, Z.K. Keane, J.E. Robinson, B. Arey, I. Arslan, and B.S. Palmer, Fabrication Artifacts and Parallel Loss Channels in Metamorphic Epitaxial Aluminum Superconducting Resonators, Supercond. Sci. Technol., 2016, 29, p 064003. https://doi.org/10.1088/0953-2048/29/6/064003

D. Niepce et al., Geometric Scaling of Two-Level-System Loss in Superconducting Resonators, Supercond. Sci. Technol., 2020, 33, p 025013. https://doi.org/10.1088/1361-6668/ab6179

B. Sopori, V. Mehta, P. Rupnowski, H. Moutinho, A. Shaikh, C. Khadilkar, M. Bennett, and D. Carlson, Studies on Backside Al-Contact Formation in Si Solar Cells: Fundamental Mechanisms, MRS Online Proceedings Library (OPL), 1123: Symposium P – Photovoltaic Materials and Manufacturing Issues 2008 p. 07. https://doi.org/10.1557/PROC-1123-1123-P07-11

V.A. Popovich, M. Janssen, I.M. Richardson, T. van Amstel, and I.J. Bennett, Microstructure and Mechanical Properties of Aluminum Back Contact Layers, Solar Energy Mater. Solar Cells, 2011, 95(1), p 93. https://doi.org/10.1016/j.solmat.2010.04.037

E. Urrejola, K. Peter, H. Plagwitz, and G. Schubert, Silicon Diffusion in Aluminum for Rear Passivated Solar Cells, Appl. Phys. Lett., 2011, 98, 153508. https://doi.org/10.1063/1.3579541

D. Alonso-Álvareza, A. Augusto, P. Pearce, L. Ferre Llin, A. Mellor, S. Bowden, D.J. Paul, and N. Ekins-Daukes, Thermal Emissivity of Silicon Heterojunction Solar Cells, Solar Energy Mater. Solar Cells, 2019, 201, p 110051. https://doi.org/10.1016/j.solmat.2019.110051

C. Park, S. Chung, N. Balaji, S. Ahn, S. Lee, J. Par, and J. Yi, Analysis of Contact Reaction Phenomenon Between Aluminum-Silver and p+ Diffused Layer for n-Type c-Si, Solar Cell Appl. Energies, 2020, 13, p 4537. https://doi.org/10.3390/en13174537

X. Huang, X. Dong, and L. Liua, Peijie Li Liquid Structure of Al-Si Alloy: A Molecular Dynamics Simulation, J. Non-Cryst. Solids, 2019, 503–504, p 182. https://doi.org/10.1016/j.jnoncrysol.2018.09.047

J. Qin, S. Pan, Y. Qi, and Gu. Tingkun, The Structure and Thermodynamic Properties of Liquid Al–Si Alloys by ab Initio Molecular Dynamics Simulation, J. Non-Cryst. Solids, 2016, 433, p 31. https://doi.org/10.1016/j.jnoncrysol.2015.11.032

S. Wang, C.Z. Wang, F.C. Chuang, J.R. Morris, and K.M. Ho, Ab initio Molecular Dynamics Simulation of Liquid Al88Si12 alloys, J. Chem. Phys., 2005, 122, p 034508. https://doi.org/10.1063/1.1833355

M. Ji, and X.G. Gong, Ab Initio Molecular Dynamics Simulation on Temperature-Dependent Properties of Al–Si Liquid Alloy, J. Phys. Condens. Matter, 2004, 16, p 2507. https://doi.org/10.1088/0953-8984/16/15/004

V.R. Manga, and D.R. Poirier, Ab Initio Molecular Dynamics Simulation of Self-Diffusion in Al–Si Binary Melts, Model. Simul. Mater. Sci. Eng., 2018, 26, p 065006. https://doi.org/10.1088/1361-651X/aacdbc

Z. Zhang, and H.M. Urbassek, Dislocations Penetrating an Al/Si Interface, AIP Adv., 2017, 7, p 125119. https://doi.org/10.1063/1.5008886

P. Saidi, and J.J. Hoyt, Atomistic Simulation of the Step Mobility at the Al–Si(111) Crystal–Melt Interface Using Molecular Dynamics, Comput. Mater. Sci., 2016, 111, p 137. https://doi.org/10.1016/j.commatsci.2015.09.040

S. Liu, X. Zhou, W. Weikang, X. Zhu, Y. Duan, H. Li, and X. Wang, Molecular Dynamics Study on the Nucleation of Al–Si Melts on Sheet Substrates at the Nanoscale, Nanoscale, 2016, 8, p 4520. https://doi.org/10.1039/C5NR06097D

B. Jelinek, S. Groh, M.F. Horstemeyer, J. Houze, S.G. Kim, G.J. Wagner, A. Moitra, and M.I. Baskes, Modified Embedded Atom Method Potential for Al, Si, Mg, Cu, and Fe Alloys, Phys. Rev. B, 2012, 85(24), p 245102. https://doi.org/10.1103/PhysRevB.85.245102

D.C. Rapaport The Art of Molecular Dynamics Simulation, (Cambridge University Press, Cambridge, 1995), https://doi.org/10.1017/CBO9780511816581

V. Plechystyy, I. Shtablavyi, S. Winczewski, K. Rybacki, S. Mudry, and J. Rybicki, Structure of the Interlayer Between Au Thin Film and Si-Substrate: Molecular Dynamics simulations, Mater. Res. Express, 2020, 7, 026553. https://doi.org/10.1088/2053-1591/ab5e76

V. Plechystyy, I. Shtablavyi, S. Winczewski, K. Rybacki, B. Tsizh, S. Mudry, and J. Rybicki, Effect of Heat Treatment on the Diffusion Intermixing and Structure of the Cu Thin Film on Si (111) Substrate: A Molecular Dynamics Simulation Study, Mol. Simul., 2021, 47(17), p 1381. https://doi.org/10.1080/08927022.2021.1974433

T.B. Massalski, Binary alloy phase diagram. ASM, Metals Park, OH, 1990.

G. Celotti, D. Nobili, and P. Ostoja, Lattice Parameter Study of Silicon Uniformly Doped with Boron and Phosphorus, J. Mater. Sci., 1974, 9, p 821. https://doi.org/10.1007/BF00761802

S.H. Kellington, D. Loveridge, and J.M. Titman, The Lattice Parameters of Some Alloys of Lithium, J. Phys. D Appl. Phys., 1969, 2, p 1162. https://doi.org/10.1088/0022-3727/2/8/415

Y. Waseda, The Structure of Non Crystalline Materials. McGraw-Hill, New York, 1980.

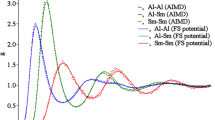

I. Shtablavyi, S. Mudry, V. Mykhaylyuk, and J. Rybicki, The Structre of Al–Cu and Al–Si Eutectic Melts, J. Non-Cryst. Solids, 2008, 354, p 4469. https://doi.org/10.1016/j.jnoncrysol.2008.06.071

S. Mudry, A. Korolyshyn, and I. Shtablavyi, The Structure Changes in Al0,88Si0,12 Eutectic Melt upon Addition of Ni, J. Phys. Conf. Series, 2008, 98, p 012016. https://doi.org/10.1088/1742-6596/98/1/012016

A.A. Akhkubekov, Analysis of the Process of Onset and Growth of a Liquid Phase in Contact of Dissimilar Crystals, J. Eng. Phys. Thermophys., 2000, 73(4), p 863. https://doi.org/10.1007/s10891-000-0105-6

M.H. Cohen, and D. Turnbull, Molecular Transport in Liquids and Glasses, J. Chem. Phys., 1959, 31(5), p 1164. https://doi.org/10.1063/1.1730566

R. Simha, and G. Carri, Free Volume, Hole Theory and Thermal Properties, J. Polym. Sci. Part B Polym. Physics, 1994, 32, p 2645. https://doi.org/10.1002/polb.1994.090321610

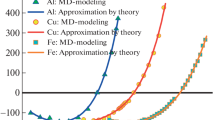

G. Kaptay, A New Theoretical Equation for Temperature Dependent Self-Diffusion Coefficients of Pure Liquid Metals, Int. J. Mat. Res., 2008, 99, p 14. https://doi.org/10.3139/146.101600

W. Chen, L. Zhang, Du. Yong, and B. Huang, Viscosity and Diffusivity in Melts: from Unary to Multicomponent Systems, Phil. Mag., 2014, 94(14), p 1552. https://doi.org/10.1080/14786435.2014.890755

E.T. Turkdogan, Activation Enthalpy of Self-Diffusion in Pure Metals Interpreted as a Measure of their Interatomic Force Constant, Can. Metall. Q., 2002, 41(4), p 441. https://doi.org/10.1179/cmq.2002.41.4.441

E.T. Turkdogan, Rationale on the Parameters of Diffusion in Solid and Liquid Metals, Molten Halides and Slags, Can. Metall. Q., 2003, 42(1), p 71. https://doi.org/10.1179/cmq.2003.42.1.71

G. Voronoi, Nouvelles applications des paramètres continus à la théorie des formes quadratiques Premier mémoire. Sur quelques propriétés des formes quadratiques positives parfaits, Journal für die Reine und Angewandte Mathematik, 1908, 133, p 97. https://doi.org/10.1515/crll.1908.133.97

N.N. Medvedev, V.P. Voloshin, V.A. Luchnikov, and M.L. Gavrilova, An Algorithm for Three-Dimensional Voronoi S-Network, J. Comput. Chem., 2006, 27, p 1676. https://doi.org/10.1002/jcc.20484

Acknowledgments

The authors gratefully acknowledge the TASK Academic Computer Centre (Gdansk, Poland) for providing the computer time and facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Plechystyy, V., Shtablavyi, I., Tsizh, B. et al. Atomic Composition and Structure Evolution of the Solid-Liquid Boundary in Al-Si System During Interfacial Diffusion and Contact Melting. J. Phase Equilib. Diffus. 43, 256–265 (2022). https://doi.org/10.1007/s11669-022-00955-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-022-00955-8