Abstract

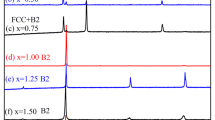

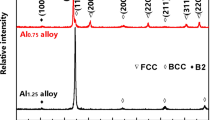

The phase constituent, phase stability, microstructure, and hardness of seven arc melted AlxCr2-xCoFeNi (x = 0.25~1.75) high-entropy alloys, in as-cast and 800 or 1000°C annealed states, were investigated using XRD, SEM, EDS and DSC. With the increase of Al content, the FCC phase disappeared in the as-cast AlxCr2-xCoFeNi alloys. As for the as-cast alloys with 25~30 at.%Al, the composition difference between the former and the later solidified B2 phase can be clearly identified. As for the AlxCr2-xCoFeNi (x = 0.25~1.0) alloys, the σ phase formed at above 576°C and decomposed at 912~1033°C. Fine FCC, BCC, B2 and σ phases existed in the 800°C annealed AlxCr2-xCoFeNi (x = 0.25~1.25) alloys. And the hardness became higher than that of the as-cast alloys. When the Al content was 25 at.%, the hardness of the alloy decreased significantly with the disappearance of the σ phase. After annealing at 1000°C, the σ phase only existed in the Al0.25Cr1.75CoFeNi and Al0.5Cr1.5CoFeNi alloys. With the increase of Al content, the alloy hardness also increased. Prolonging the annealing time, from 120 h to 480 h, can decrease the Al content in precipitated FCC or BCC phases and coarsen the phase grains, which will decrease of the alloy hardness. In all, the change of hardness after annealing depends on the contributions of formation of the harder σ phase or the softer FCC/BCC phases and the grain size of the precipitates. The results will help design the composition and treatment process of Al-Co-Cr-Fe-Ni high-entropy alloys.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsaua, and S.Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

C.C. Tung, J.W. Yeh, and T.T. Shun, On the elemental effect of AlCoCrCuFeNi high-entropy alloy system, Mater. Lett., 2007, 61(1), p 1–5

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys, Intermetallics, 2011, 19(5), p 698–706

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, and H.Z. Fu, Microstructure and compressive properties of AlCrFeCoNi high entropy alloy, Mater. Sci. Eng. A, 2008, 491(1), p 154–158

H.F. Sheng, M. Gong, and L.M. Peng, Microstructural characterization and mechanical properties of an Al0.5CoCrFeCuNi high-entropy alloy in as-cast and heat-treated/quenched conditions, Mater. Sci. Eng. A, 2013, 567, p 14–20

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, and J.W. Yeh, Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys, Intermetallics, 2012, 26, p 44–51

C.C. Yen, H.N. Lu, M.H. Tsai, B.W. Wu, Y.C. Lo, C.C. Wang, S.Y. Chang, and S.K. Yen, Corrosion mechanism of annealed equiatomic AlCoCrFeNi tri-phase high-entropy alloy in 0.5 M H2SO4 aerated aqueous solution, Corros. Sci., 2019, 157, p 462–471

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys, Acta Mater., 2011, 59(16), p 6308–6317

C. Li, J.C. Li, M. Zhao, and Q. Jiang, Effect of aluminum contents on microstructure and properties of AlxCoCrFeNi alloys, J. Alloys Compd., 2010, 504, p S515–S518

A. Munitz, S. Salhov, S. Hayun, and N. Frage, Heat treatment impacts the micro-structure and mechanical properties of AlCoCrFeNi high entropy alloy, J. Alloys Compd., 2016, 683, p 221–230

A. Sourav, S. Yebaji, and S. Thangaraju, Structure-property relationships in hot forged AlxCoCrFeNi high entropy alloys, Mater. Sci. Eng. A, 2020, 793, p 139877

M.M. Garlapati, M. Vaidya, A. Karati, S. Mishra, R. Bhattacharya, and B.S. Murty, Influence of Al content on thermal stability of nanocrystalline AlxCoCrFeNi high entropy alloys at low and intermediate temperatures, Adv. Powder Technol., 2020, 31(5), p 1985–1993

L. Huang, Y. Sun, A. Amar, C. Wu, X. Liu, G. Le, X. Wang, J. Wu, K. Li, C. Jiang, and J. Li, Microstructure evolution and mechanical properties of AlxCoCrFeNi high-entropy alloys by laser melting deposition, Vacuum, 2021, 183, p 109875

Y. Shi, J. Mo, F.-Y. Zhang, B. Yang, P.K. Liaw, and Y. Zhao, In-situ visualization of corrosion behavior of AlxCoCrFeNi high-entropy alloys during electrochemical polarization, J. Alloys Compd., 2020, 844, p 156014

Y.Y.-C. Yang, C. Liu, C.-Y. Lin, and Z. Xia, Core effect of local atomic configuration and design principles in AlxCoCrFeNi high-entropy alloys, Scripta Mater., 2020, 178, p 181–186

J. Joseph, N. Haghdadi, K. Shamlaye, P. Hodgson, M. Barnett, and D. Fabijanic, The sliding wear behaviour of CoCrFeMnNi and AlxCoCrFeNi high entropy alloys at elevated temperatures, Wear, 2019, 428–429, p 32–44

G.J. Zhang, Q.W. Tian, K.X. Yin, S.Q. Niu, M.H. Wu, W.W. Wang, Y.N. Wang, and J.C. Huang, Effect of Fe on microstructure and properties of AlCoCrFexNi (x = 1.5, 2.5) high entropy alloy coatings prepared by laser cladding, Intermetallics, 2020, 119, p 106722

M. Kang, K.R. Lim, J.W. Won, and Y.S. Na, Effect of Co content on the mechanical properties of A2 and B2 phases in AlCoxCrFeNi high-entropy alloys, J. Alloys Compd., 2018, 769, p 808–812

G. Qin, W. Xue, C. Fan, R. Chen, L. Wang, Y. Su, H. Ding, and J. Guo, Effect of Co content on phase formation and mechanical properties of (AlCoCrFeNi)100-xCox high-entropy alloys, Mater. Sci. Eng. A, 2018, 710, p 200–205

Z. Tang, O.N. Senkov, C.M. Parish, C. Zhang, F. Zhang, L.J. Santodonato, G. Wang, G. Zhao, F. Yang, and P.K. Liaw, Tensile ductility of an AlCoCrFeNi multi-phase high-entropy alloy through hot isostatic pressing (HIP) and homogenization, Mater. Sci. Eng. A, 2015, 647, p 229–240

G. Muthupandi, K.R. Lim, Y.-S. Na, J. Park, D. Lee, H. Kim, S. Park, and Y.S. Choi, Pile-up and sink-in nanoindentation behaviors in AlCoCrFeNi multi-phase high entropy alloy, Mater. Sci. Eng. A, 2017, 696, p 146–154

K.R. Lim, K.S. Lee, J.S. Lee, J.Y. Kim, H.J. Chang, and Y.S. Na, Dual-phase high-entropy alloys for high-temperature structural applications, J. Alloys Compd., 2017, 728, p 1235–1238

C. Zhang, F. Zhang, H. Diao, M.C. Gao, Z. Tang, J.D. Poplawsky, and P.K. Liaw, Understanding phase stability of Al-Co-Cr-Fe-Ni high entropy alloys, Mater. Des., 2016, 109, p 425–433

Y. Sun, C. Wu, H. Peng, Y. Liu, J. Wang, and X. Su, Phase constituent and microhardness of as-cast and long-time annealed AlxCo2-xCrFeNi multicomponent alloys, J. Phase Equilibria Diffus., 2019, 40(5), p 706–714

W. Xiong, C.J. Wu, C. Zhou, Y. Liu, and X.P. Su, Effect of annealing temperature on microstructure and hardness of the Al-Co-Cr-Fe-Ni high entropy alloys with eutectic structure and single phase, J. Changzhou Univ. Nat. Sci. Edit., 2021, 33(3), p 1–8

Z.G. Zhu, K.H. Ma, X. Yang, and C.H. Shek, Annealing effect on the phase stability and mechanical properties of (FeNiCrMn)(100–x)Cox high entropy alloys, J. Alloys Compd., 2017, 695, p 2945–2950

E. Strumza, and S. Hayun, Comprehensive study of phase transitions in equiatomic AlCoCrFeNi high-entropy alloy, J. Alloys Compd., 2021, 856, p 158220

Y. Zhao, Y. Yang, C.-H. Lee, and W. Xiong, Investigation on phase stability of AlxCo0.2Cr0.2Ni0.2Ti0.4-x high entropy alloys, J. Phase Equ. Diffus., 2018, 39(5), p 610–622

M. Tian, C. Wu, Y. Liu, H. Peng, J. Wang, and X. Su, Phase stability and microhardness of CoCrFeMnxNi2-x high entropy alloys, J. Alloys Compd., 2019, 811, p 152025

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, and E.P. George, Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures, Acta Mater., 2016, 112, p 40–52

L. Zhang, D. Zhou, and B. Li, Anomalous microstructure and excellent mechanical properties of Ni35Al21.67Cr21.67Fe21.67 high-entropy alloy with BCC and B2 structure, Mater. Lett., 2018, 216, p 252–255

S. Guo, C. Ng, and C.T. Liu, Sunflower-like Solidification Microstructure in a Near-eutectic High-entropy Alloy, Mater. Res. Lett., 2013, 1(4), p 228–232

Y.C. Liu, S.Y. Yen, S.H. Chu, S.K. Lin, and M.H. Tsai, Mechanical and thermodynamic data-driven design of Al-Co-Cr-Fe-Ni multi-principal element alloys, Mater. Today Commun., 2021, 26, p 102096

K. Osintsev, S. Konovalov, V. Gromov, I. Panchenko, and X. Chen, Phase composition prediction of Al-Co-Cr-Fe-Ni high entropy alloy system based on thermodynamic and electronic properties calculations[J], Mater. Today: Proc., 2021. https://doi.org/10.1016/j.matpr.2021.01.079

Acknowledgements

The authors gratefully acknowledge the financial support from National Natural Science Foundation of China (Nos. 51771035 and 51871030), and the Priority Academic Program Development of Jiangsu Higher Education Institutions. The authors would like to thank Xuehui An from CompuTherm LLC for thermodynamic calculation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiong, W., Wu, C., Liu, Y. et al. Phase Stability and Microhardness of the AlxCr2-xCoFeNi High-Entropy Alloys. J. Phase Equilib. Diffus. 42, 379–388 (2021). https://doi.org/10.1007/s11669-021-00890-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-021-00890-0