Abstract

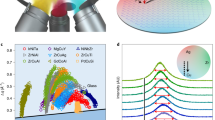

In this work, high throughput calculation (HTC) is used to identify composition regions with good glass forming ability (GFA) in the Al-Cu-Zr, Cu-Ni-Zr, Cu-Ti-Zr, Cu-Ni-Ti-Zr, Al-Cu-Ni-Ti-Zr, Mg-Ca-Cu, and Mg-Ca-Ni systems. The predicted composition regions agree well with those observed by experiments in the ternary systems, while less satisfactory agreement is found in the Cu-Ni-Ti-Zr quaternary and the Al-Cu-Ni-Ti-Zr quinary systems. The possible causes that lead to the deviation in the higher order systems are discussed. The major advantage of the HTC method used in this study is that it is simple and can be easily applied to multicomponent systems. The color maps of liquidus temperature and solidification range obtained by HTC provide a valuable guidance to the experimentalists, thus they can focus on the composition regions with high potential of forming bulk metallic glasses, avoid unnecessary trial-and-error test and save time and cost. This approach can also be combined with other criteria to filter compositions with better GFA.

Similar content being viewed by others

References

W. Klement, R.H. Willens, and P. Duwez, Non-crystalline Structure in Solidified Gold-Silicon Alloys. Nature 187(4740), 869–870 (1960)

D. Turnbull, Under What Conditions can a Glass be Formed?. Contemp. Phys. 10, 473–488 (1969)

A. Inoue, T. Zhang, and T. Masumoto, Glass-Forming Ability of Alloys. J. Non-cryst. Solids 156–158, 473–480 (1993)

Z.P. Lu and C.T. Liu, A New Glass-Forming Ability Criterion for Bulk Metallic Glasses. Acta Mater. 50(13), 3501–3512 (2002)

Q.J. Chen, J. Shen, H.B. Fan, J.F. Sun, Y.J. Huang, and D.G. Mccartney, Glass-Forming Ability of an Iorn-Based Alloy Enhanced by Co Addition and Evaluated by a New Criterion. Chin. Phys. Lett. 22(7), 1736–1738 (2005)

G.J. Fan, H. Choo, and P.K. Liaw, A New Criterion for the Glass-Forming Ability of Liquids. J. Non-cryst. Solids. 353(1), 102–107 (2007)

Z.Z. Yuan, S.L. Bao, Y. Lu, D.P. Zhang, and L. Yao, A New Criterion for Evaluating the Glass-Forming Ability of Bulk Glass Forming Alloys, J. Alloy. Compd. 459(1–2), 251–260 (2008)

X.L. Ji and Y. Pan, A Thermodynamic Approach to Assess Glass-Forming Ability of Bulk Metallic Glasses. Trans. Nonferrous Metals Soc. China 19(5), 1271–1279 (2009)

S. Guo and C.T. Liu, New Glass Forming Ability Criterion Derived from Cooling Consideration. Intermetallics 18(11), 2065–2068 (2010)

A. Inoue, Bulk Amorphous Alloys: Preparation and Fundamental Characteristics, (Trans Tech Publications LTD, 1998)

W.L. Johnson, Bulk Glass-Forming Metallic Alloys: Science and Technology, MRS Bull. 24(10), 42–56 (1999)

N. Saunders and A.P. Miodownik, Evaluation of Glass Forming Ability in Binary and Ternary Metallic Alloy Systems: An Application of Thermodynamic Phase Diagram Calculation. Mater. Sci. Technol. 4(9), 768–777 (1988)

C. Tang, H. Zhou, Thermodynamics and the glass forming ability of alloys, in Thermodynamics: Physical Chemistry of Aqueous Systemsed, ed. by J.C. Moreno-Piraján (InTech, 2011), pp. 49–72

W.A. Johnson and R.F. Mehl, Reaction Kinetics in Processes of Nucleation and Growth. Trans. AIME. 135, 416–458 (1939)

M. Avrami, Kinetics of Phase Change. II, Transformation-Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 8(2), 212–224 (1940)

L. Kaufman and H. Bernstein (ed.), Computer Calculation of Phase Diagrams, (Academic Press, New York, 1970)

Y.A. Chang, S.L. Chen, F. Zhang, X.Y. Yan, F.Y. Xie, R. Schmid-Fetzer, and W.A. Oates, Phase Diagram Calculation: Past, Present and Future. Prog. Mater. Sci. 49, 313–345 (2004)

F.C. Kracek, The System Sodium Oxide-Silica. J. Phys. Chem. 34(7), 1583–1598 (1929)

X.-Y. Yan, Y.A. Chang, Y. Yang, F.-Y. Xie, S.-L. Chen, F. Zhang, S. Daniel, and M.-H. He, A Thermodynamic Approach for Predicting the Tendency of Multicomponent Metallic Alloys for Glass Formation. Intermetallics 9(6), 535–538 (2001)

D. Ma, H. Cao, L. Ding, and Y.A. Chang, Bulkier Glass Formability Enhanced by Minor Alloying Additions. Appl. Phys. Lett. 87, 171914 (2005)

H. Cao, D. Ma, K.-C. Hsieh, L. Ding, W.G. Stratton, P.M. Voyles, Y. Pan, M. Cai, J.T. Dickinson, and Y.A. Chang, Computational Thermodynamics to Identify Zr-Ti-Ni-Cu-Al Alloys with High Glass-Forming Ability. Acta Mater. 54(11), 2975–2982 (2006)

D. Wang, H. Tan, and Y. Li, Multiple Maxima of GFA in Three Adjacent Eutectics in Zr-Cu-Al Alloy System: A Metallographic Way to Pinpoint the Best Glass Forming Alloys. Acta Mater. 53(10), 2969–2979 (2005)

B.W. Zhou, X.G. Zhang, W. Zhang, H. Kimura, A. Makino, and A. Inoue, High Glass Forming Ability and Good Mechanical Properties of Cu-Zr-Al Bulk Metallic Glasses. Mater. Res. Innov. 15(5), 310–313 (2011)

Q. Zhang, W. Zhang, G. Xie, and A. Inoue, Glass-Forming Ability and Mechanical Properties of the Ternary Cu-Zr-Al and Quaternary Cu-Zr-Al-Ag Bulk Metallic Glasses. Mater. Trans. 48(7), 1626–1630 (2007)

H. Yang, J.Q. Wang, and Y. Li, Glass Formation in the Ternary Zr-Zr2Cu-Zr2Ni System. J. Non-cryst. Solids 352(8), 832–836 (2006)

C.-J. Hu and P.-Y. Lee, Formation of Cu-Zr-Ni Amorphous Powders with Significant Supercooled Liquid Region by Mechanical Alloying Technique. Mater. Chem. Phys. 74(1), 13–18 (2002)

T. Zhang, A. Inoue, and T. Masumoto, Amorphous (Ti, Zr, Hf)-Ni-Cu Ternary Alloys with a Wide Supercooled Liquid Region. Mater. Sci. Eng., A 181–182, 1423–1426 (1994)

C.L. Dai, H. Guo, Y. Li, and J. Xu, A New Composition Zone of Bulk Metallic Glass Formation in the Cu-Zr-Ti Ternary System and Its Correlation with the Eutectic Reaction. J. Non-cryst. Solids 354, 3659–3665 (2008)

X.H. Lin and W.L. Johnson, Formation of Ti-Zr-Cu-Ni Bulk Metallic Glasses, J. Appl. Phys. Lett. 78(11), 6514–6519 (1995)

A. Inoue, W. Zhang, T. Zhang, and K. Kurosaka, High-Strength Cu-Based Bulk Glassy Alloys in Cu-Zr-Ti and Cu-Hf-Ti Ternary Systems. Acta Mater. 49(14), 2645–2652 (2001)

K.S.N.S. Idury, B.S. Murty, and J. Bhatt, Thermodynamic Modeling and Composition Design for the Formation of Zr-Ti-Cu-Ni-Al High Entropy Bulk Metallic Glasses. Intermetallics 65, 42–50 (2015)

O.N. Senkov, J.M. Scott, and D.B. Miracle, Composition Range and Glass Forming Ability of Ternary Ca-Mg-Cu Bulk Metallic Glasses. J. Alloy. Compd. 424, 394–399 (2006)

K.J. Laws, J.D. Cao, C. Reddy, K.F. Shamlaye, B. Gun, and M. Ferry, Ultra Magnesium-Rich, Low-Density Mg-Ni-Ca Bulk Metallic Glasses. Scr. Mater. 88, 37–40 (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

This invited article is part of a special issue of the Journal of Phase Equilibria and Diffusion in honor of Prof. Zhanpeng Jin’s 80th birthday. The special issue was organized by Prof. Ji-Cheng (JC) Zhao, The Ohio State University; Dr. Qing Chen, Thermo-Calc Software AB; and Prof. Yong Du, Central South University.

Rights and permissions

About this article

Cite this article

Zhang, F., Zhang, C., Lv, D. et al. Prediction of Glass Forming Ability Through High Throughput Calculation. J. Phase Equilib. Diffus. 39, 562–570 (2018). https://doi.org/10.1007/s11669-018-0643-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-018-0643-2