Abstract

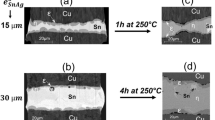

In this paper, a computational multi-phase field approach is utilized to study the formation of the Cu/Sn/Cu micro-joint in 3-Dimensional Integrated Circuits (3DICs). The method considers the evolution of the system during isothermal solidification at 250 °C for the case of two different interlayer thicknesses (5 and 10 µm). The Cu/Sn/Cu interconnection structure is important for the micro packaging in the 3DIC systems. The thermodynamics and kinetics of growth of η-Cu6Sn5 and ɛ-Cu3Sn interfacial intermetallics (IMCs) are investigated by coupling the multi-phase field method with CALPHAD approach. The interaction of the phases is addressed by assuming a metastable condition for the Cu/Sn reacting system. The simulations start with the nucleation and rapid growth of the η-Cu6Sn5 IMCs at the initial stage, the nucleation and growth of ɛ-Cu3Sn IMCs at the intermediate stage ending with the full consumption of Sn layer and the domination of ɛ-Cu3Sn IMCs at the later stages. In addition, comparing different diffusion rates through the grain boundary of η phases show that their morphology is the direct consequence of balance of kinetic forces. This work provides a valuable understanding of the dominant mechanisms for mass transport in the Cu/Sn/Cu low volume interconnections. The results show that the phase field modeling is successful in addressing the morphological evolution and growth of IMC layers in the 3DIC joint formation.

Similar content being viewed by others

References

M.L. Huang and F. Yang, Size Effect Model on Kinetics of Interfacial Reaction Between Sn-xAg-yCu Solders and Cu Substrate, Sci. Rep., 2014, 4, p 7117

H.-Y. Hsiao, C.-M. Liu, H. Lin, T.-C. Liu, C.-L. Lu, Y.-S. Huang, C. Chen, and K.N. Tu, Unidirectional Growth of Microbumps on (111)-Oriented and Nanotwinned Copper, Science, 2012, 336, p 1007-1010

K.N. Tu, Reliability Challenges in 3D IC Packaging Technology, Microelectron. Reliab., 2011, 51, p 517-523

M. Ohyama, M. Nimura, J. Mizuno, S. Shoji, T. Nonaka, Y. Shinba, and A. Shigetou, Evaluation of Hybrid Bonding Technology of Single-Micron Pitch with Planar Structure for 3D Interconnection. Microelectron. Reliab.

K.N. Tu and T. Tian, Metallurgical Challenges in Microelectronic 3D IC Packaging Technology for Future Consumer Electronic Products, Sci. China Technol. Sci., 2013, 56, p 1740-1748

W.D. MacDonald and T.W. Eagar, Transient Liquid Phase Bonding, Annu. Rev. Mater. Sci., 1992, 22, p 23-46

R. Gagliano and M.E. Fine, Growth of η Phase Scallops and Whiskers in Liquid Tin-Solid Copper Reaction Couples, JOM, 2001, 53, p 33-38

M.S. Park, M.K. Stephenson, C. Shannon, L.A. Cáceres Díaz, K.A. Hudspeth, S.L. Gibbons, J. Muñoz-Saldaña, and R. Arróyave, Experimental and Computational Study of the Morphological Evolution of Intermetallic Compound (Cu6Sn5) Layers at the Cu/Sn Interface Under Isothermal Soldering Conditions, Acta Mater., 2012, 60, p 5125-5134

J. Görlich, G. Schmitz, and K.N. Tu, On the Mechanism of the Binary Cu/Sn Solder Reaction, Appl. Phys. Lett., 2005, 86, p 053106

C. Zhang and G. Sun, Fabrication cost analysis for 2D, 2.5D, and 3D IC designs. In 3D Systems Integration Conference (3DIC), 2011 IEEE International; 2012; pp. 1-4.

G.O.C. Iii and C.D. Sorensen, Overview of Transient Liquid Phase and Partial Transient Liquid Phase Bonding, J. Mater. Sci., 2011, 46, p 5305-5323

J.R. Davis, Copper and Copper Alloys, ASM International, Materials Park, 2001

J.-H. Shim and C.-S. Oh, Thermodynamic Assessment of the Cu-Sn System, Z. Fuer Met. Res. Adv. Tech., 1996, 87, p 205-212

Q. Yin, F. Gao, Z. Gu, E.A. Stach, and G. Zhou, In Situ Visualization of Metallurgical Reactions in Nanoscale Cu/Sn Diffusion Couples, Nanoscale, 2015, 7, p 4984-4994

J.Y. Huh, K.K. Hong, Y.B. Kim, and K.T. Kim, Phase Field Simulations of Intermetallic Compound Growth During Soldering Reactions, J. Electron. Mater., 2004, 33, p 1161-1170

M.S. Park and R. Arroyave, Formation and Growth of Intermetallic Compound Cu6Sn5 at Early Stages in Lead-Free Soldering, J. Electron. Mater., 2010, 39, p 2574-2582

M. Ode, T. Koyama, H. Onodera, and T. Suzuki, Phase-field Modeling for Sn-Bi Soldering, J. Electron. Mater., 2003, 32, p 1534-1539

J.P. Simmons, Y. Wen, C. Shen, and Y.Z. Wang, Microstructural Development Involving Nucleation and Growth Phenomena Simulated with the Phase Field Method, Mater. Sci. Eng. A, 2004, 365, p 136-143

C.-C. Pan, C.-H. Yu, and K.-L. Lin, The Amorphous Origin and the Nucleation of Intermetallic Compounds Formed at the Interface During the Soldering of Sn–3.0Ag–0.5Cu on a Cu Substrate, Appl. Phys. Lett., 2008, 93, p 061912

H. Lin, C. Lu, C. Liu, C. Chen, D. Chen, J.-C. Kuo, and K.N. Tu, Microstructure Control of Unidirectional Growth of η-Cu6Sn5 in Microbumps on 〈111〉 Oriented and Nanotwinned Cu, Acta Mater., 2013, 61, p 4910-4919

J.C. Strikwerda, Finite Difference Schemes and Partial Differential Equations, SIAM, Philadelphia, 2004

M.S. Park and R. Arróyave, Concurrent Nucleation, Formation and Growth of Two Intermetallic Compounds (Cu6Sn5 and Cu3Sn) During the early Stages of Lead-Free Soldering, Acta Mater., 2012, 60, p 923-934

M.S. Park and R. Arróyave, Multiphase Field Simulations of Intermetallic Compound Growth During Lead-Free Soldering, J. Electron. Mater., 2009, 38, p 2525-2533

B.F. Dyson, T.R. Anthony, and D. Turnbull, Interstitial Diffusion of Copper in Tin, J. Appl. Phys., 1967, 38, p 3408

J.S. Kang, R.A. Gagliano, G. Ghosh, and M.E. Fine, Isothermal Solidification of Cu/Sn Diffusion Couples to Form Thin-Solder Joints, J. Electron. Mater., 2002, 31, p 1238-1243

Y.T. Chunjin Hang, Phase transformation and grain orientation of Cu–Sn intermetallic compounds during low temperature bonding process, J. Mater. Sci. Mater. Electron., 2013, 24, p 3905-3913

V.I. Dybkov, Growth Kinetics of Chemical Compound Layers, Cambridge Int Science Publishing, Cambridge, 1998

N. Zhao, Y. Zhong, M.L. Huang, H.T. Ma, and W. Dong, Growth Kinetics of Cu6Sn5 Intermetallic Compound at Liquid-Solid Interfaces in Cu/Sn/Cu Interconnects Under Temperature Gradient, Sci. Rep., 2015, 5, p 13491

D. Li, P. Franke, S. Fürtauer, D. Cupid, and H. Flandorfer, The Cu–Sn Phase Diagram Part II: New Thermodynamic Assessment, Intermetallics, 2013, 34, p 148-158

Acknowledgment

The authors would like to acknowledge the ADA cluster in the Texas A&M Supercomputing Facility, for providing computing resources useful in conducting the research reported in this paper. The authors acknowledge Dr. Thien Duong and Mrs. Kubra Karayagiz for useful discussions. This research was supported by the National Science Foundation under NSF Grant No. CMMI-1462255.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The free energy densities per unit molar volume of individual phases are:

where \(G_{\text{Cu}}^{\alpha }\) = −19073, \(G_{\text{Sn}}^{\alpha }\) = −27280, \(G_{\text{Cu}}^{L}\) = −11083, \(G_{\text{Sn}}^{\text{SER}}\) = 346160, \(G_{\text{Sn}}^{L}\) = −28963, L α0 = −11448, L α1 = −11694, L L0 = −10487, L L1 = −18198, L L2 = 10528.4.

Rights and permissions

About this article

Cite this article

Attari, V., Arroyave, R. Phase Field Modeling of Joint Formation During Isothermal Solidification in 3DIC Micro Packaging. J. Phase Equilib. Diffus. 37, 469–480 (2016). https://doi.org/10.1007/s11669-016-0475-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-016-0475-x