Abstract

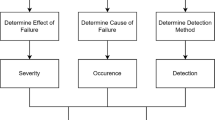

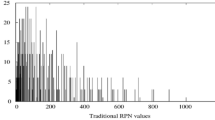

Applying the fuzzy logic method to FMEA and its correlation with performance investigations is rarely applied in analyzing refrigeration system risk. The aim of this study is investigate the refrigeration system performance and analyze the risk of failure mode in the performance of the refrigeration system using the fuzzy-FMEA method. In calculating performance, the COP parameter is needed. Prioritization of failure modes uses conventional FMEA (C-FMEA) and fuzzy-based FMEA (Fuzzy-FMEA), which produces conventional RPN (C-RPN) and fuzzy-RPN (F-RPN). Pareto diagrams are used to classify RPN categories which are the main causes. The result of the study is that the calculation of the refrigeration system performance shows a decreasing trend with increasing operating time. In the risk analysis, it was found that the F21 (evaporator) failure has the same rating, and the highest is C-RPN (252) and F-RPN (750). Five categories need to be mitigated. The application of fuzzy-FMEA determines the critical failure priority of the evaporator. The results of this study provide new insights into developing engine performance investigations by determining critical failure modes to get mitigation quickly by minimizing expert opinion expertise.

Similar content being viewed by others

References

L. Franceschelli, A. Berardinelli, S. Dabbou, L. Ragni, M. Tartagni, Sensing technology for fish freshness and safety: a review. Sensors. 21, 1–24 (2021)

A.C. Yilmaz, Performance evaluation of a refrigeration system using nanolubricant. Appl. Nanosci.Nanosci. 10, 1667–1678 (2020)

J. Balaraju, M. Govinda Raj, C.S. Murthy, Fuzzy-FMEA risk evaluation approach for LHD machine-A case study. J. Sustain. Min. 18, 257–268 (2019)

I. Alsyouf, The role of maintenance in improving companies’ productivity and profitability. Int. J. Prod. Econ. 105, 70–78 (2007)

Y. Wang, G. Cheng, H. Hu, W. Wu, Development of a risk-based maintenance strategy using FMEA for a continuous catalytic reforming plant. J. Loss Prev. Process Ind. 25, 958–965 (2012)

J.S. Tan, M.A. Kramer, A general framework for preventive maintenance optimization in chemical process operations. Comput. Chem. Engng. 21, 1451–1469 (1997)

F. Backlund, J. Hannu, Can we make maintenance decisions on risk analysis results? J. Qual. Maint. Eng.Maint. Eng. 8, 77–91 (2002)

S. Baldi, T. Le Quang, O. Holub, P. Endel, Real-time monitoring energy efficiency and performance degradation of condensing boilers. Energy Convers. Manag. 136, 329–339 (2017)

G. Bogdanovská, V. Molnár, G. Fedorko, Failure analysis of condensing units for refrigerators with refrigerant R134a, R404A. Int. J. Refrig.Refrig. 100, 208–219 (2019)

K. Chandra, V. Kain, P.S. Shetty, R. Kishan, Failure analysis of copper tube used in a refrigerating plant. Eng. Fail. Anal. 37, 1–11 (2014)

H. Arabian-Hoseynabadi, H. Oraee, P.J. Tavner, Failure modes and effects analysis (FMEA) for wind turbines. Int. J. Electr. Power Energy Syst. Electr. Power Energy Syst. 32, 817–824 (2010)

A. Jomde, V. Bhojwani, S. Kedia, N. Jangale, K. Kolas, P. Khedkar, S. Deshmukh, Failure modes effects and criticality analysis of the linear compressor. Mater. Today: Proc. 4(9), 10184–10188 (2017). https://doi.org/10.1016/j.matpr.2017.06.345

K.P. Lijesh, S.M. Muzakkir, H. Hirani, Failure mode and effect analysis of passive magnetic bearing. Eng. Fail. Anal. 62, 1–20 (2016)

E. Adar, M. Ince, B. Karatop, M.S. Bilgili, The risk analysis by failure mode and effect analysis (FMEA) and fuzzy-FMEA of supercritical water gasification system used in the sewage sludge treatment. J. Environ. Chem. Eng. 5, 1261–1268 (2017)

H. Li, H. Díaz, C. GuedesSoares, A failure analysis of floating offshore wind turbines using AHP-FMEA methodology. Ocean Eng. 234, 109261 (2021)

A. Mariajayaprakash, T. Senthilvelan, Failure detection and optimization of sugar mill boiler using FMEA and Taguchi method. Eng. Fail. Anal. 30, 17–26 (2013)

J.F.W. Peeters, R.J.I. Basten, T. Tinga, Improving failure analysis efficiency by combining FTA and FMEA in a recursive manner. Reliab. Eng. Syst. Saf.. Eng. Syst. Saf. 172, 36–44 (2018)

J.R. Ribas, J.C.R. Severo, L.F. Guimarães, K.P.C. Perpetuo, A fuzzy FMEA assessment of hydroelectric earth dam failure modes: a case study in Central Brazil. Energy Rep. 7, 4412–4424 (2021)

D.V. Petrović, M. Tanasijević, V. Milić, N. Lilić, S. Stojadinović, I. Svrkota, Risk assessment model of mining equipment failure based on fuzzy logic. Expert Syst. Appl. 41, 8157–8164 (2014)

K. Xu, L.C. Tang, M. Xie, S.L. Ho, M.L. Zhu, Fuzzy assessment of FMEA for engine systems. Reliab. Eng. Syst. Saf. Eng. Syst. Saf. 75, 17–29 (2002)

R. Yahmadi, K. Brik, F. Ben Ammar, Fuzzy risk priority number assessment for solar gel battery manufacturing defects. Eng. Fail. Anal. 124, 105327 (2021)

Z. Yang, J. Wang, Use of fuzzy risk assessment in FMEA of offshore engineering systems. Ocean Eng. 95, 195–204 (2015)

H. Gargama, S.K. Chaturvedi, Criticality assessment models for failure mode effects and criticality analysis using fuzzy logic. IEEE Trans. Reliab.Reliab. 60, 102–110 (2011)

G.A. Keskin, C. Özkan, An alternative evaluation of FMEA: fuzzy ART algorithm. Qual. Reliab. Eng. Int.Reliab. Eng. Int. 25, 647–661 (2009)

S.S. Baakeem, J. Orfi, A. Alabdulkarem, Optimization of a multistage vapor-compression refrigeration system for various refrigerants. Appl. Therm. Eng. 136, 84–96 (2018)

M. H. A. Baig, S. G. Prasanthi, (2013) Failure modes and effect analysis of a mechanical assembly by using Mil-Std 1629a Method. Int. J. Adv. Inform. Sci. Technol. (IJAIST) 13: 2.

R. Rakesh, B.C. Jos, G. Mathew, FMEA analysis for reducing breakdowns of a sub system in the life care product manufacturing industry. Int. J. Eng. Sci. Innov. Technol. (IJESIT). 2, 218–225 (2013)

R. Bubbico, S. Di Cave, B. Mazzarotta, Risk analysis for road and rail transport of hazardous materials: a simplified approach. J. Loss Prev. Process Ind. 17, 477–482 (2004)

R. Khasha, M.M. Sepehri, T. Khatibi, A fuzzy FMEA approach to prioritizing surgical cancellation factors. Int J Hosp Res. 2, 17–24 (2013)

J. Yang, H.Z. Huang, L.P. He, S.P. Zhu, D. Wen, Risk evaluation in failure mode and effects analysis of aircraft turbine rotor blades using Dempster-Shafer evidence theory under uncertainty. Eng. Fail. Anal. 18, 2084–2092 (2011)

C. Dağsuyu, E. Göçmen, M. Narlı, A. Kokangül, Classical and fuzzy FMEA risk analysis in a sterilization unit. Comput. Ind. Eng.. Ind. Eng. 101, 286–294 (2016)

K.M. Tay, C.P. Lim, Fuzzy FMEA with a guided rules reduction system for prioritization of failures. Int. J. Quality Reliab. Manage. 23, 1047–1066 (2006)

D.V. Petrović, M. Tanasijević, S. Stojadinović, J. Ivaz, P. Stojković, Fuzzy model for risk assessment of machinery failures. Symmetry. 12, 525 (2020)

R.K. Sharma, D. Kumar, P. Kumar, Systematic failure mode effect analysis (FMEA) using fuzzy linguistic modelling. Int. J. Quality Reliab. Manage. 22, 986–1004 (2005)

C.W. Nugroho, T. Pitana, B. Dinariyana, Risk analysis using job safety analysis-fuzzy integration for ship maintenance operation. IPTEK J. Technol. Sci. 31, 327 (2020)

J. Kaur, R. Sidhu, A. Awasthi, S.K. Srivastava, A Pareto investigation on critical barriers in green supply chain management. Int. J. Manage. Sci. Eng. Manage. 14, 113–123 (2019)

H.R. Feili, N. Akar, H. Lotfizadeh, M. Bairampour, S. Nasiri, Risk analysis of geothermal power plants using failure modes and effects analysis (FMEA) technique. Energy Convers. Manag. 72, 69–76 (2013)

Q. Wang, T. Li, Y. Jia, W. Zhang, Thermodynamic performance comparison of series and parallel two-stage evaporation vapor compression refrigeration cycle. Energy Rep. 7, 1616–1626 (2021)

K. Arumuganainar, M. Edwin, J.B. Raj, Investigation on the performance improvement of household refrigeration system using R-134a refrigerant blended with ceria nano additives. Appl. Nanosci.Nanosci. 12, 1753–1761 (2022)

M.R. Braun, P. Walton, S.B.M. Beck, Illustrating the relationship between the coefficient of performance and the coefficient of system performance by means of an R404 supermarket refrigeration system. Int. J. Refrig.Refrig. 70, 225–234 (2016)

S.M. Ch, N. Ch, D. Samal, S. Kumar, P. Garre, A. Review, Increase in performance of vapour compression refrigeration system using fan. Int. J. Eng. Appl. Sci. (IJEAS). 2, 12–14 (2015)

M.C. Constantino, F.T. Kanizawa, Evaluation of pressure drop effect on COP of single-stage vapor compression refrigeration cycles. Thermal Sci. Eng. Progress. 28, 101048 (2022)

J.B. Bowles, C. Enrique Peldez, Fuzzy logic prioritization of failures in a system failure mode. Effects Crit. Anal. 50, 203–213 (1995)

M.J. Kalathil, V.R. Renjith, N.R. Augustine, Failure mode effect and criticality analysis using dempster shafer theory and its comparison with fuzzy failure mode effect and criticality analysis: a case study applied to LNG storage facility. Process. Saf. Environ. Prot.Saf. Environ. Prot. 138, 337–348 (2020)

A.A.A.A. Al-Rashed, Effect of evaporator temperature on vapor compression refrigeration system. Alex. Eng. J. 50, 283–290 (2011)

S. Khatoon, M.N. Karimi, Thermodynamic analysis of two evaporator vapor compression refrigeration system with low GWP refrigerants in automobiles. Int. J. Air-Cond. Refr. 31, 2 (2023)

A.M. Kumar, S. Rajakarunakaran, P. Pitchipoo, R. Vimalesan, Fuzzy based risk prioritisation in an auto LPG dispensing station. Saf. Sci.. Sci. 101, 231–247 (2018)

A. Mascia, A.M. Cirafici, A. Bongiovanni, G. Colotti, G. Lacerra, M. Di Carlo, F.A. Digilio, G.L. Liguori, A. Lanati, A. Kisslinger, A failure mode and effect analysis (FMEA)-based approach for risk assessment of scientific processes in non-regulated research laboratories. Accred. Qual. Assur.. Qual. Assur. 25, 311–321 (2020)

V.R. Renjith, P.H. Kumar, D. Madhavan, Fuzzy FMECA (failure mode effect and criticality analysis) of LNG storage facility. J. Loss Prev. Process Ind. 56, 537–547 (2018)

J. Ivančan, D. Lisjak, New FMEA risks ranking approach utilizing four fuzzy logic systems. Machines. 9, 292 (2021)

Y. Yoon, H. Jeong, K.S. Lee, Adaptive defrost methods for improving defrosting efficiency of household refrigerator. Energy Convers. Manag. 157, 511–516 (2018)

S. K. Akula, H. Salehfar, S. Behzadirafi, in 2022 North American Power Symposium (NAPS) (2022), pp. 1–6.

Y.E. Priharanto, R.I. Yaqin, G. Marjianto, J.P. Siahaan, M.Z.L. Abrori, Risk assessment of the fishing vessel main engine by fuzzy-FMEA approach. J. Fail. Anal. Prev. 23, 822–836 (2023)

L. Cruz-Rivero, M.L. Méndez-Hernández, C.E. Mar-Orozco, A.A. Aguilar-Lasserre, A. Barbosa-Moreno, J. Sánchez-Escobar, Functional evaluation using fuzzy FMEA for a non-invasive measurer for methane and carbone dioxide. Symmetry. 14, 421 (2022)

K. Tanabe, Pareto’s 80/20 rule and the Gaussian distribution. Physica A A. 510, 635–640 (2018)

A. Tayal, N.S. Kalsi, M.K. Gupta, D.Y. Pimenov, M. Sarikaya, C.I. Pruncu, Effectiveness improvement in manufacturing industry; trilogy study and open innovation dynamics. J. Open Innov. Technol. Market, Complex. 7, 1–21 (2021)

Acknowledgment

All authors thank all fishing vessel crews in Batam who have given their time and energy in collecting the necessary data. The author also thanks the Politeknik Kelautan dan Perikanan Dumai for supporting and facilitating the creation of fuzzy logic.

Funding

It is certified that the author has not received funding from any institution to carry out this research work.

Author information

Authors and Affiliations

Contributions

All authors have equal participation and teamwork to complete this research paper. All authors read and approved the manuscript made to the end.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no potential conflict of interest regarding this article.

Ethical Approval

The author has been approved for ethical clearance with number 0030/KEPK/Adm2/II/2023 in connection with this research work.

Consent to Participate

Not applicable.

Consent to Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Siahaan, J.P., Yaqin, R.I., Priharanto, Y.E. et al. Risk-Based Maintenance Strategies on Fishing Vessel Refrigeration Systems Using Fuzzy-FMEA. J Fail. Anal. and Preven. 24, 855–876 (2024). https://doi.org/10.1007/s11668-024-01878-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01878-x