Abstract

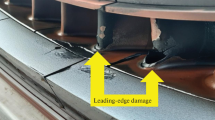

Second-stage gas turbine nozzles are an important part of the gas turbine due to their performance in hot temperature conditions. In this investigation, service-induced failure analysis and microstructural variations of different sides of a second-stage nozzle in a 100 MW gas turbine made of FSX-414 cobalt-based alloy were comprehensively studied to determine the conditions and mechanisms of the failure process. The primary carbides M3C2 and M7C3 types were converted to secondary carbides M23C6 type by phase transformation process and formed a continuous layer in the grain boundaries owing to high-temperature operation conditions. A network of cracks was created in the grain boundaries, leading to a fracture in the vane of the nozzle. The continuity and density of the produced carbides decreased ductility and toughness of the nozzle. The results demonstrated that hot oxidation and sulfidation occurred in the leading-edge zone. The aggregation and asymmetry of the combustion line and, consequently, the increasing temperature were the reasons for the damage. Some macrocracks were observed by visual inspection on the surface of the nozzle owing to exposure to high temperatures and placement in the path of the hot gas with high pressure. Based on the results, the continuous and coarse brittle M23C6 carbides on the grain boundaries were the major cause of the failure due to the crack growth caused by stress corrosion. These carbides provided appropriate paths for the growth of the crack through grain boundaries, leading to failure after the operational out-of-service condition of a second-stage gas turbine nozzle. Operational in over-hot conditions and an inappropriate filtration system were the main reasons for the operational-induced thermal fatigue failure process of the second-stage gas turbine nozzles. Based on the results, oxidation and microstructural variations were the main causes of the failure process of the second-stage gas turbine nozzles.

Similar content being viewed by others

Data and code availability

Not applicable.

References

T. Giampaolo, Gas Turbine Handbook: Principles and Practice, 5th edn. (Fairmont Press, Lilburn, Georgia, 2013)

Z. Mazur, A. Luna-Ramirez, J.A. Juarez-Islas, A. Campos-Amezcua, Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 12, 474–486 (2005)

N. Eliaz, G. Shemesh, R.M. Latanision, Hot corrosion in gas turbine components. Eng. Fail. Anal. 9, 31–43 (2002)

M.R. Shirpay, H. Kazempour-Liacy, Failure analysis of a repaired gas turbine nozzle. J. Fail. Anal. Preven. 13, 243–248 (2013)

Z. Mazur, A. Hernandez-Rossette, R. Garcia-Illescas, A. Luna-Ramirez, Failure analysis of a gas turbine nozzle. Eng. Fail. Anal. 15, 913–921 (2008)

Y.V. Nawancy, L.M. Al-Hadhrami, Degradation of turbine blades and vanes by overheating in a power station. Eng. Fail. Anal. 16, 273–280 (2009)

R. Citarella, G. Cricri, M. Lepore, M. Perrella, Thermo-mechanical crack propagation in aircraft engine vane by coupled FEM–DBEM approach. Adv. Eng. Softw. 67, 57–69 (2014)

X. Wu, Z. Zhang, L. Jiang, P. Patnaik, Material selection issues for a nozzle guide vane against service-induced failure. J. Eng. Gas Turb. Pow. 139, 052101–052106 (2017)

N. Birks, G.H. Meier, F.S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd edn. (Cambridge University Press, U.K., 2006)

S.D. Cramer, B.S. Covino, Corrosion: Environments and Industries, ASM Handbook, 13C ASM International. (Materials Park, Ohio, 2006)

T.J. Carter, Common failure in gas turbine blades. Eng. Fail. Anal. 12, 237–247 (2005)

L.K. Bhagi, V. Rastogi, Fractographic investigations of the failure of L-1 low pressure turbine blade. Case Stud. Eng. Fail. Anal. 1, 72–78 (2013)

J.A. Daleo, K.A. Ellison, D.H. Boone, Metallurgical considerations for life assessment and the safe refurbishment and requalification of gas turbine blades. J. Eng. Gas. Turb. Pow. 124, 571–579 (2002)

Kh. Rahmani, A. Torabian, Influence of welding on low cycle fatigue properties of Co-based superalloy FSX-414. Trans. Nonferrous Metals Soc. China. 26, 1326–1335 (2016)

O. Çoban, Ö.C. Arslan, T. Karahan, Failure analysis of jet turbine engine high pressure nozzle material made of cobalt based super alloy. Int. J. Eng. Nat. Sci. 1(1), 13–20 (2018)

M.F. Gazulla, M.J. Ventura, C. Andreu, J. Gilabert, M. Orduna, M. Rodrigo, Characterization of cobalt oxides transformation with temperature at different atmospheres. Int. J. Chem. Sci. 17, 1–9 (2019)

G.M. Kale, S.S. Pandit, K.T. Jacob, Thermodynamics of cobalt (II, III) oxide (Co3O4) evidence of phase transition. Trans. Japan Metals. 29, 125–132 (1988)

S. Fathi, Sh. Zangeneh, M. Pahlavani, A comprehensive analysis of premature failure in a cobalt-based superalloy X-45 gas turbine vane. J. Fail. Anal. Preven. 19, 1337–1347 (2019)

F.M. Yang, X.F. Sun, H.R. Guan, Z.Q. Hu, On the low cycle fatigue deformation of K40S cobalt-base superalloy at elevated temperature. Mater. Lett. 57, 2823–2828 (2003)

Sh. Zangeneh, H. Farhangi, Influence of service-induced microstructural changes on the failure of a cobalt-based superalloy first stage nozzle. Mater. Des. 31, 3504–3511 (2010)

A. Luna Ramirez, J.P. Calderon, Z. Mazur, V.M. Salinas-Bravo, L. Martinez-Gomez, Microstructural changes during high temperature service of a cobalt-based superalloy first stage nozzle. Adv. Mater. Sci. Eng. 1, 1–7 (2016)

E. Poursaeidi, M. Aieneravaie, M.R. Mohammadi, Failure analysis of a second stage blade in a gas turbine engine. Eng. Fail. Anal. 15, 1111–1129 (2008)

B. Salehnasab, E. Poursaeidi, S.A. Mortazavi, G.H. Farokhian, Hot corrosion failure in the first stage nozzle of a gas turbine engine. Eng. Fail. Anal. 60, 316–325 (2016)

A.A. Malekbarmi, S. Zangeneh, A. Roshani, Assessment of premature failure in a first stage gas turbine nozzle. Eng. Fail. Anal. 18, 1262–1271 (2011)

E. Kosieniak, K. Biesiada, J. Kaczorowski, M. Innocenti, Corrosion failures in gas turbine hot components. J. Fail. Anal. Preven. 12, 330–337 (2012)

M.P. Boyce, The Gas Turbine Handbook, 2nd edn. (Gulf Professional Publishing, Houston, Texas, 2002)

W. Gui, H. Zhang, M. Yang, T. Jin, X. Sun, Q. Zheng, The investigation of carbides evolution in a cobalt-base superalloy at elevated temperature. J. Alloys Compd. 695, 127–1278 (2017)

F.M. Yang, X.F. Sun, H.R. Guan, Z.Q. Hu, The effect of reheat treatment on microstructure and stress rupture property of a directionally solidified nickel based superalloy after long-term thermal exposure. Mater. Sci. Eng. A. 694, 48–56 (2017)

S. Li, B. Wang, D. Shi, X. Yang, H. Qi, A physically based model for correlating the microstructural degradation and residual creep lifetime of a polycrystalline Ni based superalloy. J. Alloys Compd. 783, 565–573 (2019)

S.S. Hwang, Y.S. Lim, S.W. Kim, D.J. Kim, H.P. Kim, Role of grain boundary carbides in cracking behavior of Ni base alloys. Nucl. Eng. Technol. 45, 73–80 (2013)

Y. Liu, Y. Wu, J. Yu, J. Ju, Z. Zhang, M. Kang, J. Wang, B. Sun, Y. Ning, Temperature-dependent deformation mechanisms and microstructural degradation of a polycrystalline nickel-based superalloy. J. Alloys Compd. 775, 181–192 (2019)

G.Y. Lai, High temperature corrosion and materials applications. (Materials Park, Ohio, 2007)

R. Santorelli, E. Sivieri, R.C. Reggiani, High temperature corrosion of several commercial Fe-Cr-Ni alloys under a molten sodium sulphate deposit in oxidizing gaseous environments. Mater. Sci. Eng. 120, 283–291 (1989)

M.R. Khajavi, M.H. Shariat, Failure of first stage gas turbine blades. Eng. Fail. Anal. 11, 589–597 (2004)

T.S. Chowdhury, F.T. Mohsin, M.M. Tonni, M.N. Mita, M.M. Ehsan, A critical review on gas turbine cooling performance and failure analysis of turbine blades. Int. J. Thermofluids. 18, 100329 (2023)

S.K.S. Al Adawi, G.R. Rameshkumar, Vibration diagnosis approach for industrial gas turbine and failure analysis. Br. J. Appl. Sci. Technol. 14(2), 1–9 (2016)

B.A. Mohamad, A. Abdelhussien, Failure analysis of gas turbine blade using finite element analysis. Int. J. Mech. Eng. Technol. 7(3), 299–305 (2016)

S. Rani, A.K. Agrawal, V. Rastogi, Failure analysis of a first stage IN738 gas turbine blade tip cracking in a thermal power plant, Case Stud. Eng. Fail. Anal. 8, 1–10 (2017)

P. Puspitasari, A. Andoko, P. Kurniawan, Failure analysis of a gas turbine blade: a review. IOP Conf. Ser. Mater. Sci. Eng. 1034(1), 012156 (2021)

S. Kumari, D.V.V. Satyanarayana, M. Srinivas, Failure analysis of gas turbine rotor blades. Eng. Fail. Anal. 45, 234–244 (2014)

H. Kazempour-Liasi, A. Shafiei, Z. Lalegani, Failure analysis of first and second stage gas turbine blades. J. Fail. Anal. Prev. 19(6), 1673–1682 (2019)

Z. Huda, Metallurgical failure analysis for a blade failed in a gas-turbine engine of a power plant. Mater. Des. 30(8), 3121–3125 (2009)

S. Qu, C.M. Fu, C. Dong, J.F. Tian, Z.F. Zhang, Failure analysis of the 1st stage blades in gas turbine engine. Eng. Fail. Anal. 32, 292–303 (2013)

S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. Gijbels, Failure analysis of a third stage gas turbine blade. Eng. Fail. Anal. 18(1), 386–393 (2011)

J.C. Chang, Y.H. Yun, C. Choi, J.C. Kim, Failure analysis of gas turbine buckets. Eng. Fail. Anal. 10(5), 559–567 (2003)

A.M. Mirhosseini, S.A. Nazari, A.M. Pour, S.E. Haghighi, M. Zareh, Failure analysis of first stage nozzle in a heavy-duty gas turbine. Eng. Fail. Anal. 109, 104303 (2020)

G.H. Farrahi, M. Tirehdast, E.M. Abad, S. Parsa, M. Motakefpoor, Failure analysis of a gas turbine compressor. Eng. Fail. Anal. 18(1), 474–484 (2011)

N. Vardar, A. Ekerim, Failure analysis of gas turbine blades in a thermal power plant. Eng. Fail. Anal. 14(4), 743–749 (2007)

R. Wang, B. Zhang, D. Hu, K. Jiang, H. Liu, J. Mao, F. Jing, X. Hao, Thermomechanical fatigue experiment and failure analysis on a nickel-based superalloy turbine blade. Eng. Fail. Anal. 102(37), 35–45 (2019)

Z. Mazur, A. Luna-Ramirez, J.A. Juárez-Islas, A. Campos-Amezcua, Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 12(3), 474–486 (2005)

B. Swain, P. Mallick, S. Patel, R. Roshan, S.S. Mohapatra, S. Bhuyan, M. Priyadarshini, B. Behera, S. Samal, A. Behera, Failure analysis and materials development of gas turbine blades. Mater. Today Proc. 33(8), 5143–5146 (2020)

R.K. Mishra, P. Kumar, K. Rajesh, C.R. Das, G. Sharma, D.K. Srivastava, Life enhancement of nozzle guide vane of an aero gas turbine engine through pack aluminization. Int. J. Turbo Jet Engines. 38(1), 51–58 (2021)

R.K. Mishra, J. Thomas, K. Srinivasan, V. Nandi, R. Bhat, Failure analysis of nozzle guide vane of a low pressure turbine in an aero gas turbine engine. J. Fail. Anal. Prev. 14, 578–587 (2014)

M. Jafari Eskandari, M. Karimi, M. Araghchi, A. Hadipour, Laser cleaning process of high-pressure turbine blade: characterization and removal of surface contaminants. Surf. Coat. Technol. 470, 129885 (2023)

Acknowledgments

In addition, the authors gratefully acknowledge the financial support of the SEM, XRD, OM, laser, and metallographic laboratories of National Center for R&D of Materials Science and Engineering.

Author information

Authors and Affiliations

Contributions

Ali Hadipour was involved in conceptualization, methodology, visualization, investigation, data curation, reviewing and editing. Mohammad Jafari Eskandari contributed to conceptualization, methodology, data curation, writing—original draft preparation, visualization, investigation, writing—reviewing and editing, reviewing and editing. Mohammad Ghasem Gholami contributed to reviewing and editing. Mohsen Mehdizadeh contributed to reviewing and editing.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hadipour, A., Jafari Eskandari, M., Gholami, M.G. et al. Failure Analysis of the Various Sides of a Second-Stage Gas Turbine Nozzle Made of FSX-414 Cobalt-Based Alloy. J Fail. Anal. and Preven. 24, 838–854 (2024). https://doi.org/10.1007/s11668-024-01877-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01877-y