Abstract

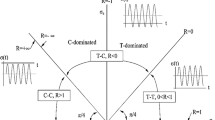

It is crucial to propose an accurate fatigue life prediction method to ensure the structural integrity and operational reliability of engineering components in real-world service conditions. This paper considers how the uncertainty of fatigue failure in composite materials under variable amplitude loading conditions affects material fatigue life. It proposes an improved method to predict the residual fatigue life of a composite material by converting the number of loading cycles under different loading sequences. Firstly, the method suggests that the number of loading cycles for the same composite material, under variable amplitude loading conditions and at different stress levels, conforms to the assumptions of the Weibull cumulative distribution and the principle of probabilistic consistency. Using this assumption, a transformation model is established for the number of cyclic loading cycles in composite materials under variable amplitude loading conditions. Specifically, the model can convert the number of loading cycles under various loading sequences into an equivalent number of cycles under a uniform loading condition. Next, the residual fatigue life of the specimen at the final stress level was determined by analyzing fatigue test data under variable amplitude loading conditions. Finally, the proposed method is validated and compared using fatigue test data from the literature, which includes composites tested under two and three variable amplitude loading conditions. Validation results indicate that the proposed method for predicting residual fatigue life offers more accurate predictions, with all predicted life factors falling within ± 1.2 life factors. Additionally, compared to other existing models for predicting residual life, the proposed method effectively captures the impact of randomness and uncertainty in the fatigue failure process of composite materials using probabilistic statistical theory. This offers a more valuable reference for predicting fatigue life under variable amplitude load.

Similar content being viewed by others

References

J. Gao, C. Wang, Z. Xu et al., Gaussian process regression based remaining fatigue life prediction for metallic materials under two-step loading. Int. J. Fatigue. 158, 106730 (2022)

J. Gao, Y. Yuan, Probabilistic model of fatigue damage accumulation of materials based on the principle of failure probability equivalence. Structures. 28, 659–667 (2020)

J. Liu, X. Liu, An improved method for fatigue life prediction of metal materials based on thermodynamic entropy. Int. J. Fatigue. 170, 107546 (2023)

N.D. Batsoulas, Cumulative fatigue damage: CDM-based engineering rule and life prediction aspect. Steel Res. Int. 87, 1670–1677 (2016)

L. Gan, X. Zhao, H. Wu et al., Estimation of remaining fatigue life under two-step loading based on kernel-extreme learning machine. Int. J. Fatigue. 148, 106190 (2021)

Z. Peng, H.-Z. Huang, J. Zhou et al., A new cumulative fatigue damage rule based on dynamic residual SN curve and material memory concept. Metals. 8, 456 (2018)

S. Yang, L. Yang, Y. Wang, Determining the fatigue parameters in total strain life equation of a material based on monotonic tensile mechanical properties. Eng. Fract. Mech. 226, 106866 (2020)

H. Wang, H. Liao, X. Ma, Remaining useful life prediction considering joint dependency of degradation rate and variation on time-varying operating conditions. IEEE Trans. Reliab. 70, 761–774 (2020)

S. Feng, X. Han, Z. Li et al., Ensemble learning for remaining fatigue life prediction of structures with stochastic parameters: a data-driven approach. Appl. Math. Model. 101, 420–431 (2022)

S.P. Zhu, Y.Z. Hao, J.A. de Oliveira Correia et al., Nonlinear fatigue damage accumulation and life prediction of metals: a comparative study. Fatigue Fract. Eng. Mater. Struct. 42, 1271–1282 (2019)

F. Silva, The importance of compressive stresses on fatigue crack propagation rate. Int. J. Fatigue. 27, 1441–1452 (2005)

R.M. Nejad, Z. Liu, W. Ma et al., Reliability analysis of fatigue crack growth for rail steel under variable amplitude service loading conditions and wear. Int. J. Fatigue. 152, 106450 (2021)

Q.-Y. Deng, S.-P. Zhu, J.-C. He et al., Multiaxial fatigue under variable amplitude loadings: review and solutions. Int. J. Struct. Integr. 13(3), 349–393 (2022)

F. Mozafari, P. Thamburaja, A. Srinivasa et al., Fatigue life prediction under variable amplitude loading using a microplasticity-based constitutive model. Int. J. Fatigue. 134, 105477 (2020)

F.-J. Zuo, H.-Z. Huang, S.-P. Zhu et al., Fatigue life prediction under variable amplitude loading using a non-linear damage accumulation model. Int. J. Damage Mech. 24, 767–784 (2015)

X. Yu, T. Yu, K. Song et al., RETRACTED: reliability analysis of mechanical components based on a nonlinear fatigue damage accumulation model. Int. J. Damage Mech. 28, 1135–1149 (2019)

X. Xu, Y. Li, W. Huang et al., Fatigue design of steel bridge deck asphalt pavement based on nonlinear damage accumulation theory. Appl. Sci. 11, 5668 (2021)

T. Huang, R.-C. Ding, Y.-F. Li et al., A modified model for nonlinear fatigue damage accumulation of turbine disc considering the load interaction effect. Metals. 9, 919 (2019)

M.A. Miner, Cumulative damage in fatigue. J. Appl. Mech. 12(3), A159–A164 (1945)

Z. Peng, H.-Z. Huang, H.-K. Wang et al., A new approach to the investigation of load interaction effects and its application in residual fatigue life prediction. Int. J. Damage Mech. 25, 672–690 (2016)

V. Strizhius, Estimation of the residual fatigue life of laminated composites under a multistage cyclic loading. Mech. Compos. Mater. 52, 611–622 (2016)

R. Yuan, H. Li, H.-Z. Huang et al., A nonlinear fatigue damage accumulation model considering strength degradation and its applications to fatigue reliability analysis. Int. J. Damage Mech. 24, 646–662 (2015)

M. Prabhakar, A. Prasad, M. Paswan, Influence of loading sequence and residual stresses affecting the fatigue life of axle housing and crack path analysis using local approaches. Eng. Fail. Anal. 116, 104753 (2020)

Q. Sun, H.-N. Dui, X.-L. Fan, A statistically consistent fatigue damage model based on Miner’s rule. Int. J. Fatigue. 69, 16–21 (2014)

A. Aïd, A. Amrouche, B.B. Bouiadjra et al., Fatigue life prediction under variable loading based on a new damage model. Mater. Des. 32, 183–191 (2011)

H. Usabiaga, M. Muniz-Calvente, M. Ramalle et al., Improving with probabilistic and scale features the Basquin linear and bi-linear fatigue models. Eng. Fail. Anal. 116, 104728 (2020)

S. Marco, W. Starkey, A concept of fatigue damage. Trans. Am. Soc. Mech. Eng. 76, 627–632 (1954)

K. Gao, G. Liu, Novel nonlinear time-varying fatigue reliability analysis based on the probability density evolution method. Int. J. Fatigue. 149, 106257 (2021)

Y. Chen, P. Xu, C. Liu et al., Multiaxial fatigue behavior and life prediction of 7075–T651 aluminum alloy under two-step loading. Eng. Fract. Mech. 230, 107007 (2020)

V. Dattoma, S. Giancane, R. Nobile et al., Fatigue life prediction under variable loading based on a new non-linear continuum damage mechanics model. Int. J. Fatigue. 28, 89–95 (2006)

S.-P. Zhu, D. Liao, Q. Liu et al., Nonlinear fatigue damage accumulation: Isodamage curve-based model and life prediction aspects. Int. J. Fatigue. 128, 105185 (2019)

Z. Feng, Q. Ma, Z. An et al., New fatigue life prediction model for composite materials considering load interaction effects. Int. J. Appl. Mech. 15(9), 2350076 (2023)

S. Benkabouche, H. Guechichi, A. Amrouche et al., A modified nonlinear fatigue damage accumulation model under multiaxial variable amplitude loading. Int. J. Mech. Sci. 100, 180–194 (2015)

S. Shiri, M. Yazdani, M. Pourgol-Mohammad, A fatigue damage accumulation model based on stiffness degradation of composite materials. Mater. Des. 88, 1290–1295 (2015)

J. Gao, P. Zhu, Y. Yuan et al., Strength and stiffness degradation modeling and fatigue life prediction of composite materials based on a unified fatigue damage model. Eng. Fail. Anal. 137, 106290 (2022)

H. Liu, Z. Zhang, H. Jia et al., A novel method to predict the stiffness evolution of in-service wind turbine blades based on deep learning models. Compos. Struct. 252, 112702 (2020)

J. Jang, M.M. Khonsari, On the prediction of fatigue life subjected to variable loading sequence. Fatigue Fract. Eng. Mater. Struct. 44, 2962–2974 (2021)

A. Califano, L. Grassia, A. D’Amore, Fatigue of composite materials subjected to variable loadings. J. Mater. Eng. Perform. 28, 6538–6543 (2019)

A. D’Amore, L. Grassia, A method to predict the fatigue life and the residual strength of composite materials subjected to variable amplitude (VA) loadings. Compos. Struct. 228, 111338 (2019)

A. D’Amore, L. Grassia, Principal features of fatigue and residual strength of composite materials subjected to constant amplitude (CA) loading. Materials. 12, 2586 (2019)

C. Li, S. Wu, J. Zhang et al., Determination of the fatigue PSN curves: a critical review and improved backward statistical inference method. Int. J. Fatigue. 139, 105789 (2020)

J. Gao, Y. Yuan, Small sample test approach for obtaining P–S–N curves based on a unified mathematical model. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 234, 4751–4760 (2020)

Q. Ma, Z. An, X. Bai et al., New probabilistic SN curves modeling method with small-sample test data of composite materials. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 235, 5665–5674 (2021)

W. Tianshuai, H. Xiaofan, W. Jinyu et al., Detail fatigue rating method based on bimodal Weibull distribution for DED Ti–6.5 Al–2Zr–1Mo–1V titanium alloy. Chin. J. Aeronaut. 35, 281–291 (2022)

Z.A. Cameron, T.L. Krantz, Statistical distribution of gear surface fatigue lives at high reliability. Int. J. Fatigue. 167, 107350 (2023)

M.S. Tareq, B. Jony, S. Zainuddin et al., Fatigue analysis and fracture toughness of graphene reinforced carbon fibre polymer composites. Fatigue Fract. Eng. Mater. Struct. 44, 461–474 (2021)

L. Ke, F. Zhu, Z. Chen et al., Fatigue failure mechanisms and probabilistic SN curves for CFRP–steel adhesively bonded joints. Int. J. Fatigue. 168, 107470 (2023)

L. Xie, J. Liu, N. Wu et al., Backwards statistical inference method for P–S–N curve fitting with small-sample experiment data. Int. J. Fatigue. 63, 62–67 (2014)

J.F. Barbosa, R. Carlos Silverio Freire Júnior, J.A. Correia et al., Analysis of the fatigue life estimators of the materials using small samples. J. Strain Anal. Eng. Des. 53, 699–710 (2018)

H.-C. Cheng, F.-S. Hwu, Fatigue reliability analysis of composites based on residual strength. Adv. Compos. Mater. 15, 385–402 (2006)

J. Gao, Y. Yuan, R. Xu, A framework for fatigue life prediction of materials under the multi-level cyclic loading. Eng. Fail. Anal. 127, 105496 (2021)

F. Wu, W. Yao, A fatigue damage model of composite materials. Int. J. Fatigue. 32, 134–138 (2010)

Acknowledgments

This work was supported by the National Natural Science Foundation of China [51665029], Industrial Support Plan for Colleges and Universities in Gansu Province of China [2020C-12], 2022 Higher Education Innovation Fund Project in Gansu Province of China [2022A-018], Gansu Province Science and Technology Program Funding [22JR5RA238], National Natural Science Foundation of China [52365017].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, Q., Feng, Z., Ma, H. et al. Research on Residual Life Prediction Method of Composites Based on Equivalent Number of Cycles Conversion. J Fail. Anal. and Preven. 24, 708–720 (2024). https://doi.org/10.1007/s11668-024-01875-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01875-0