Abstract

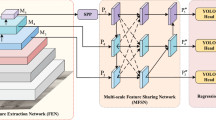

Belt conveyors are one type of the most important transportation devices for continuous transportation of bulk materials in bulk cargo piers, whose operating environments are complicated. The belt damages change in a wide scale range and multiple scales coexist. Thus, the reliability of damage detection methods is challenging. A Yolov5-based improved EMA-YOLO belt multi-scale damage detection method is put forward here. First, a high-efficiency multi-scale attention module EMA is introduced in view of there being complex background interferences in belt damage detection samples so that important areas shall be more concerned in our model. The multi-scale features can be extracted at different levels and the resistance ability of background interferences may be enhanced. Additionally, the feature fusion network is improved. The weight of learning is introduced by means of a simple and efficient weighted bidirectional feature pyramid network (BiFPN) to learn the weights of different input feature layers and modular repeated application is performed so that our model can simply and quickly fuse multi-scale features. Thus, the training performance of our model can be improved. Our measurements indicate that the accuracy of our detection method is up to 98.51%, and its detection speed is up to 82.26 FPS. Compared with the existing methods, our method can be more reliable and real time.

Similar content being viewed by others

References

S.G. Sakharwade, S. Nagpal, Analysis of transient belt stretch for horizontal and inclined belt conveyor system. Int. J. Math. Eng. Manag. Sci. 4, 1169–1179 (2019)

M. Cui, Research on longitudinal tear detection system of conveyor belt based on machine vision. (Qufu Normal University, Shandong, 2021)

M. Huang, E. Li, Y.H. Gu, Research on longitudinal tear monitoring method of steel cord core conveyor belt. J. China Univ. Mining Technol. 01, 52–55 (2002)

J. Che, Research on audio-visual fusion detection method of conveyor belt longitudinal tear based on machine learning. (Taiyuan University of Technology, Shanxi, 2021)

X.-L. Hao, H. Liang, A multi-class support vector machine real-time detection system for surface damage of conveyor belts based on visual saliency. Measurement. 146, 125–132 (2019)

J. Li, C. Miao, The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm. Optik. 127(19), 8002–8010 (2016)

G. Wang, L. Zhang, H. Sun, C. Zhu, Longitudinal tear detection of conveyor belt under uneven light based on Haar-AdaBoost and cascade algorithm. Measurement. 16, 1–10 (2021)

S. A. Hassan, S. H. Han, and S. Y. Shin, Real-time road cracks detection based on improved deep convolutional neural network, in 2020 IEEE Canadian Conference on Electrical and Computer Engineering (CCECE) (pp. 1-4). IEEE, pp. 1–4 (2020).

J. Guo, C. Liu, J. Cao, D. Jiang, Damage identification of wind turbine blades with deep convolutional neural networks. Renew. Energy. 174, 122–133 (2021)

J. Kim, J. Ko, H. Choi, H. Kim, Printed circuit board defect detection using deep learning via a skip-connected convolutional auto encoder. Sensors. 21(15), 1–13 (2021)

M. Liu, Q. Zhu, Y. Yin, Y. Fan, Z. Su, S. Zhang, Damage detection method of mining conveyor belt based on deep learning. IEEE Sens. J. 22(11), 10870–10879 (2022)

D. Cheng, J. Xu, Q. Kou et al., Lightweight network based on residual information for foreign body classification on coal conveyor belt. J. China Coal Soc. 47(03), 1361–1369 (2022)

M. Zhang, H. Shi, Y. Zhang, Y. Yu, M. Zhou, Deep learning-based damage detection of mining conveyor belt. Measurement. 175, 109130 (2021)

Y. Pu, D.B. Apel, A. Szmigiel et al., Image recognition of coal and coal gangue using a convolutional neural network and transfer learning. Energies. 12(9), 1735 (2019)

Q. Mao, S. Li, X. Hu et al., Coal mine belt conveyor foreign object recognition based on improved YOLOv7. Ind. Mine Automat. 48(12), 26–32 (2022)

S. Hao, X. Zhang, X. Ma et al., Coal mine conveyor belt foreign object detection based on CBAM-YOLOv5. Coal J. 47(11), 4147–4156 (2022)

Guo C X, Fan B, Zhang Q, et al. AugFPN: improving multi-scale feature learning for object detection, in Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR). New York: IEEE,12592–12601 (2020)

F.H. Zou, X. Wei, W.T. Ji et al., Arbitrary-oriented object detection via dense feature fusion and attention model for remote sensing super-resolution image. Neural Comput. Appl. 32(18), 14549–14562 (2020)

D. Qu, T. Qiao, Y. Pang et al., Research On ADCN method for damage detection of mining conveyor belt. IEEE Sens. J. 21(6), 8662–8669 (2021)

Y.J. Zhou, S.Y. Xu, Y.R. Huang, Conveyor belt damage detection method based on improved YOLOv4. Ind. Mine Automat. 47(11), 61–65 (2021)

Chen J, Mai H S, Luo L, et al. Effective feature fusion network in BIFPN for small object detection, in 2021 IEEE international conference on image processing (ICIP). IEEE, 699–703 (2021)

X. Ran, S. He, R. Li, Research on fatigued-driving detection method by integrating lightweight YOLOv5s and facial 3D Keypoints. Sensors. 23(19), 8267 (2023)

T.-Y. Lin, P. Doll´ar, R. Girshick, K. He, B. Hariharan, and S. Belongie, Feature pyramid networks for object detection, in Proceedings of the IEEE conference on computer vision and pattern recognition, pp. 2117–2125 (2017)

S. Liu, L. Qi, H. Qin, J. Shi, and J. Jia, “Path aggregation network for instance segmentation,” in Proceedings of the IEEE conference on computer vision and pattern recognition, pp. 8759–8768 (2018)

M. Tan, R. Pang, and Q.V. Le, “Efficientdet: Scalable and efficient object detection,” in Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp. 10781–10790 (2020)

W. Song, S.A. Suandi, Sign-YOLO: a novel lightweight detection model for Chinese traffic sign. IEEE Access. 11, 113941–113951 (2023)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, G., Wang, Y., Sun, H. et al. Study on Visual Detection Method of Multi-scale Damage to Conveyor Belt Under Complex Background. J Fail. Anal. and Preven. 24, 896–908 (2024). https://doi.org/10.1007/s11668-024-01869-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01869-y