Abstract

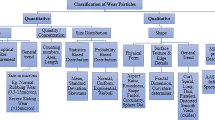

Wear is progressive deterioration of machine components by the loss of weight and shape results in generation of wear debris. For the analysis of these wear debris, ferrography method is widely used. This method was successfully used to examine the condition monitoring of martial aircraft engines, gearboxes, bearings, heavy earth moving machineries, turbines etc. Ferrographic condition monitoring as a preventive maintenance done by collecting oil sample. Ferrogram’s images taken under a microscope for monitoring wear particle contamination of these oil samples. Both qualitative and quantitative analysis of the wear particles was done from these image analyses. Novelty of this research work is use of hot ferrography for getting detailed information about machine health condition. A detailed Excel sheet containing information about the size distribution of wear particles in terms of count, area, perimeter, aspect ratio, and mean diameter was created using data from the Olympus microscope software and a ferrogram. From this data, wear mode, its source, mechanism can be easily detected.

Similar content being viewed by others

References

D. Baglee, E. Jantunen, Can equipment failure modes support the use of a condition based maintenance strategy. Procedia CIRP. 22, 87–91 (2014)

L. Ping, H.E. Powrie, R.J.K. Wood, T.J. Harvey, N.R. Harris, Early wear detection and its significance for condition monitoring. Tribol. Int. 159, 106946 (2021)

S.N. Kamble, B. Rajiv, Critical analysis of machine condition monitoring by using risk priority number and analytical hierarchy process. J Failure Anal Prevent. 22(2), 623–632 (2022)

S.N. Kamble, B. Rajiv, Significance of risk priority number in machine condition monitoring. Mater Today: Proc. 50, 1930–1935 (2022)

S. Raadnui, Condition monitoring of worm gear wear and wear particle analysis of industrial worm gear set. Wear. 476, 203687 (2021)

S. Kumar, D. Goyal, R.K. Dang, S.S. Dhami, B.S. Pabla, Condition based maintenance of bearings and gears for fault detection–A review. Mater Today: Proc. 5(2), 6128–6137 (2018)

O.G. Ehibor, B.N.G. Aliemeke, Optimization of process parameters of surface roughness and material removal rate on orthogonal turning of AISI 1045 carbon steel using Taguchi technique, Industrial Engineering Letters, pp 16–25. (2021)

T.R. Hemanth Kumar, R.P. Swamy, T.K. Chandrashekar, An experimental investigation on wear test parameters of metal matrix composites using taguchi technique. Indian J. Eng. Mater. Sci. 20, 329–333 (2013)

N.L. Parthasarathi, U. Borah, S.K. Albert, Effect of temperature on sliding wear of AISI 316 L (N) stainless steel–analysis of measured wear and surface roughness of wear tracks. Mater. Des. 51, 676–682 (2013)

J. Peter, Blau, elevated—temperature tribology of metallic materials. Tribol. Int. 43, 1203–1208 (2010)

N. Al-Araji, H. Sarhan, Effect of temperature on sliding wear mechanism under lubricated conditions. Int. J. Eng. 5, 176–184 (2011)

Arindam Roy Goswami, Santanu Sardar, Santanu Kumar Karmakar, Temperature rise and wear of sliding contact of alloy steels, International conference in mechanical engineering. AIP Conf. Proc. 1754, 1–6 (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kamble, S.N., Rajiv, B. Size Distribution of Wear Particles by Area and Perimeter Using Hot Ferrography. J Fail. Anal. and Preven. 24, 538–546 (2024). https://doi.org/10.1007/s11668-024-01855-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01855-4