Abstract

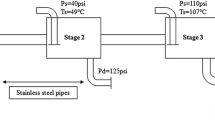

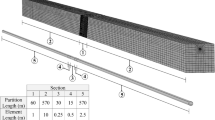

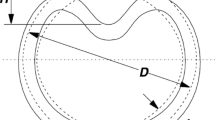

Premature failure of two upward-inclined underground pipes carrying sewage caused sinkhole formation in a busy urban road. Metallurgical failure analysis revealed that the pipes were made of ductile cast iron. External and internal coatings were appropriate to protect the pipes from external soil and internal sewage slurry corrosion. Partial filling of sewage slurry during the pumping recess allowed turbulent flow in the empty section during pumping, and the impact of turbulence eroded the internal coating, i.e., mortar lining, introduced erosion–corrosion and progressively reduced the pipe wall thickness in the upper half of the pipes resulting to weakening. Intermittent turbulence led to some localized corrosion fatigue-induced fracture in the weakened pipe wall. Erosion–corrosion with the assistance of corrosion fatigue led to the premature failure of the ductile cast iron pipes.

Similar content being viewed by others

Data availability

The authors do not have permission to share data.

References

B. Rajani, Y. Kleiner, Protecting ductile-iron water mains: what protection method works best for what soil condition? J. Am. Water Works Assoc. 95, 110–125 (2003). https://doi.org/10.1002/J.1551-8833.2003.TB10497.X

W.D. Callister, D.G. Rethwisch, Materials science and engineering: an introduction, 10th edn. (John Wiley & Sons, Singapore, 2018)

Y. Wang, Y. Zhang, R. Song, L. Huang, Y. Pei, Effect of the austenitizing temperature on microstructure evolution and impact toughness of a novel bainite ductile iron. Met. Mater. Int. 27, 4014–4022 (2021). https://doi.org/10.1007/s12540-020-00893-5

A. Water Works Service Company, Deteriorating buried infrastructure management challenges and strategies, 2002.

H.M.S. Belmonte, M. Mulheron, P.A. Smith, A. Ham, K. Wescombe, J. Whiter, Weibull-based methodology for condition assessment of cast iron water mains and its application. Fatigue Fract. Eng. Mater. Struct. 31, 370–385 (2008). https://doi.org/10.1111/J.1460-2695.2008.01233.X

M. Wasim, S. Shoaib, N.M. Mubarak, A.M.A. Inamuddin, Factors influencing corrosion of metal pipes in soils. Environ. Chem. Lett. 16, 861–879 (2018). https://doi.org/10.1007/S10311-018-0731-X

A. Fahimi, T.S. Evans, J. Farrow, D.A. Jesson, M.J. Mulheron, P.A. Smith, On the residual strength of aging cast iron trunk mains: physically-based models for asset failure. Mater. Sci. Eng. A. 663, 204–212 (2016). https://doi.org/10.1016/J.MSEA.2016.03.029

M. Liu, C. Du, X. Luo, C. Liu, Z. Wu, X. Li, Failure analysis in buried ductile iron pipelines: a study of leakage in drinking water distribution systems. Eng. Fail. Anal. 151, 107361 (2023). https://doi.org/10.1016/J.ENGFAILANAL.2023.107361

S.F. Hassan, Hydrogen induced premature failure of massive cast medium carbon steel anchor fluke. Mater. Des. 31, 956 (2010). https://doi.org/10.1016/j.matdes.2009.06.045

S.F. Hassan, Cement particle induced failure of cold potable water copper plumbing. Eng. Fail. Anal. (2010). https://doi.org/10.1016/j.engfailanal.2010.09.018

S.F. Hassan, M.R. Alam, Failure analysis of gearbox and clutch shaft from a marine engine. J. Fail. Anal. Prev. 10, 393 (2010). https://doi.org/10.1007/s11668-010-9373-4

G.H. Nam, J.K. Lee, K.J. Kim, Failure analysis of pitted copper pipes used in underground water and preventive measures. Met. Mater. Int. 24, 496–506 (2018). https://doi.org/10.1007/s12540-018-0038-2

D. Joseph R., ed., Metal handbook desk edition, 2nd ed., ASM International, Materials Park, Ohio, 1998.

ASTM A536-84 Standard specification for ductile iron castings, 1999. doi https://doi.org/10.1520/A0536-84R19E01.2

B.C. Stewart, H.R. Doude, S. Mujahid, M.B. Abney, E.T. Fox, J.E. Edmunson, J.J. Mehan, C.R. Henry, P.B. Hall, H. El Kadiri, H. Rhee, Comparison study of ductile iron produced with Martian regolith harvested iron from ionic liquids and Bosch byproduct carbon for in-situ resource utilization versus commercially available 65–45-12 ductile iron. Adv. Sp. Res. 71, 2175–2185 (2023). https://doi.org/10.1016/j.asr.2022.10.060

M.H. Nazari, J. Yu, X. Shi, Effect of ferrous alloy type, beetroot juice, Deicer type and concentration on early-stage corrosion behavior of buried pipes. J. Mater. Civ. Eng. 32, 1–11 (2020). https://doi.org/10.1061/(asce)mt.1943-5533.0003379

BS EN 598-07 Ductile Iron Pipes, Fittings, accessories and their joints for sewerage application- Requiments and Test Methods, 2007.

ASTM A746-18 Standard specification for ductile iron gravity sewer pipe, 2015. https://doi.org/10.1520/A0746-18.2.

R. Marchal, Protection of buried ductile iron pipelines with a zinc-based coating-Healing power of coating damages, in: 4th Intl. International Conference Proceedings (Internal and External Protection of Pipes. Noordwijkerhout, Netherlands, 1981.

I.S. Meland, Durability of mortar lining in ductile iron pipes, in Durab Build. Mater. ed. by M.A. Lacasse, D.J. Vanier (Components, Institute for Research in Constructio, Ottawa ON, Canada, 1999), p.170–179

B. Anna Wassilkowska, K. Kuc, M. Zielina, A study of the composition of cement mortar lining in water and sewage pipelines. Tech. Trans. Civ. Eng. 4, 131–136 (2015). https://doi.org/10.4467/2353737XCT.15.404.5035

W. Dąbrowski, F. Li, Mortar lining as a protective layer for ductile iron pipes. Int. J. Civ. Eng. 19, 369–380 (2021). https://doi.org/10.1007/S40999-020-00585-6/FIGURES/10

E. Gebreyouhannes, K. Maekawa, Nonlinear gel migration in cracked concrete and broken symmetry of corrosion profiles. J. Adv. Concr. Technol. 14, 271–286 (2016). https://doi.org/10.3151/jact.14.271

T.A. Jur, J.I. Middleton, A.A. Yurko, R.L. Windham, J.R. Grey, Case studies in graphitic corrosion of cast iron pipe. J. Fail. Anal. Prev. 21, 376–386 (2021). https://doi.org/10.1007/S11668-020-01097-0/FIGURES/21

M. BajtLeban, T. Kosec, Characterization of corrosion products formed on mild steel in deoxygenated water by Raman spectroscopy and energy dispersive x-ray spectrometry. Eng. Fail. Anal. 79, 940–950 (2017). https://doi.org/10.1016/J.ENGFAILANAL.2017.03.022

F. Iacoviello, V. Di Cocco, Influence of the graphite elements morphology on the fatigue crack propagation mechanisms in a ferritic ductile cast iron. Eng. Fract. Mech. 167, 248–258 (2016). https://doi.org/10.1016/j.engfracmech.2016.03.041

S. Xiang, P. Hedström, B. Zhu, J. Linder, J. Odqvist, Influence of graphite morphology on the corrosion-fatigue properties of the ferritic Si-Mo-Al cast iron SiMo1000. Int. J. Fatigue. 140, 105781 (2020). https://doi.org/10.1016/J.IJFATIGUE.2020.105781

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hassan, S.F. Metallurgical Investigation of Buried Ductile Cast Iron Sewerage System Pipeline Premature Failure. J Fail. Anal. and Preven. 23, 2542–2553 (2023). https://doi.org/10.1007/s11668-023-01797-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01797-3