Abstract

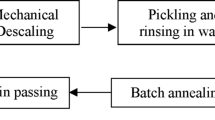

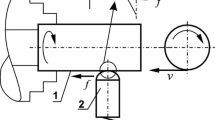

The market capitalization of the coated sheets is continuously increasing in the automotive exposed and non-exposed panels such as door inner panels, dashboard, and cowl. The production of defect-free coated steel sheets requires increasingly more stringent norms for defects are visible after painting to end customer. In the present study, we have analyzed one of the typical surface defects that appear as “Comma” shape and commonly located at the edges of galvannealed steel sheets. Using Optical microscope, Profilometer and Scanning electron microscope coupled with Energy dispersive X-ray spectroscopy we have characterized the defect. Correlation with plant process parameters has been investigated for its likely origin. Defects are observed to align at a certain angle with respect to the RD (rolling direction), and consisting of a head, a tail, and a connecting trench inside, with tail oriented toward the edge of the sheet. The formation of these defects was hypothesized to be associated with dead zone creation, splashing and consequential back-splashing of zinc droplets near edges of the sheet during air knife operation. Because a dead zone is created at the edges of sheet, these zinc droplets pass through the air knife without getting wiped off, consequentially get adhered at the strip surface. During skin pass rolling, these solidified zinc particles get rolled onto the sheet and form the observed defects on the final coated products. Usage of baffle plate in air knife assembly is recommended to reduce/annihilate formation of dead zones at the edges of the coated sheet.

Similar content being viewed by others

References

A. Azimi, F. Ashrafizadeh, M. Toroghinejad, F. Shahriari, Metallurgical characterisation of wrinkle bands and their influence on properties of galvanised steel sheet. Ironmak. Steelmak. 40, 630–634 (2013)

A. Chakraborty, M. Dutta, R. Pais, R.R. Kumar, Analysis of an uncommon coating defect on industrial galvannealed high strength interstitial free steel. Surf. Coat. Technol. 204, 3481–3489 (2010)

A. Chakraborty, A. Mondal, S. Agnihotri, R. Pais, M. Dutta, Investigation of a surface defect and its elimination in automotive grade galvannealed steels. Eng. Fail. Anal. 66, 455–467 (2016)

J.-R. Park, Noise, edge overcoating, and edge buildup phenomena associated with gas wiping in continuous hot dip galvanising and role of edge baffles. Ironmak. Steelmak. 28, 53–57 (2001)

H. Kakuno, M. Katsube, M. Ogawa. METEC & 2nd ESTAD. Retrieved from “NS blade”/Advanced air knife for hot dip continuous galvanizing line: www.metec-estad2015.com (2015)

D.W. Lee, J.G. Hwang, Y.D. Kwon, S.B. Kwon, G.Y. Kim, D.E. Lee, A study on the air knife flow with Coanda effect. J. Mech. Sci. Technol. 21, 2214–2220 (2007)

A. Mondal, A.K. Halder, S. Nayak, A. Kumar, A. Chakraborty, S. Shukla, S. Sahoo, R.S. Pais, M. Dutta, Root cause analysis of an uncommon surface defect on galvannealed steel sheet. Eng. Fail. Anal. 93, 64–75 (2018)

K. Pulidindi, A. Prakash. Coated steel market. Retrieved from Global Market Insights: https://www.gminsights.com/industry-analysis/coated-steel-market (2021)

P. Saravanan, S. Srikanth, Surface defects and their control in hot dip galvanized and galvannealed sheets. Int. J. Adv. Res. Chem. Sci. 5, 11–23 (2018)

A.R. Shankar, U.K. Mudali, B. Raj, Failure analysis of pin prick defects in galvannealed sheet—a case study. Eng. Fail. Anal. 16, 2485–2492 (2009)

S. Yuan, X. Zhou, Y. Huang, P. Yang, Influence of air knives on liquid zinc flow in galvanising bath. Ironmak. Steelmak. 43, 83–87 (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pranay Teja, K.S., Monia, S., Mukhopadhyay, G. et al. Investigation of Indentation Type Surface Defect on Interstitial Free Galvannealed Steel Sheet During Zinc Coating. J Fail. Anal. and Preven. 23, 2182–2190 (2023). https://doi.org/10.1007/s11668-023-01768-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01768-8