Abstract

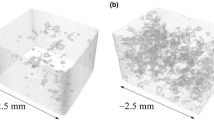

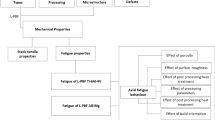

The functionality of load-bearing parts remains a central challenge for laser-powder bed fusion (L-PBF). However, the understanding and quantification of the process–quality–fatigue (P-Q-F) causal relationship are still lacking. The variable fatigue behavior is randomized by the PBF process variations and the subsequent quality uncertainty, e.g., random geometrical defects. In particular, the bulk literature is limited to gross fatigue fracture, while the fatigue initiation and development process is poorly understood due to the constraint of available online fatigue monitoring techniques. Addressing these challenges is critical to qualify L-PBF as a standard industrial process for fabricating load-bearing metal parts. From the scientific point of view, the effect of a wide range of porosity on fatigue performance is yet to be studied to understand the P-Q-F causal relationship even though low porosity more completely is desired in L-PBF parts. This work focuses on resonance-based fatigue testing of as-PBFed SS-316L material with random porosity. The results have shown that frequency and power are process signatures for fatigue initiation, development, and gross fracture. The porosity-induced fatigue life and fatigue limit scattering show normal distributions.

Similar content being viewed by others

References

M. Attaran, The rise of 3-D printing: the advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 60(5), 677–688 (2017). https://doi.org/10.1016/j.bushor.2017.05.011

S. Gruber, C. Grunert, M. Riede, E. López, A. Marquardt, F. Brueckner, C. Leyens, Comparison of dimensional accuracy and tolerances of powder bed based and nozzle based additive manufacturing processes. J. Laser Appl. 32(3), 032016 (2020). https://doi.org/10.2351/7.0000115

L. Cui, F. Jiang, R.L. Peng, R.T. Mousavian, Z. Yang, J. Moverare, Dependence of microstructures on fatigue performance of polycrystals: a comparative study of conventional and additively manufactured 316L stainless steel. Int. J. Plast. 149, 103172 (2022). https://doi.org/10.1016/j.ijplas.2021.103172

S.N. Dryepondt, B.A. Pint, D. Ryan, Comparison of electron beam and laser beam powder bed fusion additive manufacturing process for high temperature turbine component materials, Office of Scientific and Technical Information (OSTI) (2016). https://doi.org/10.2172/1248786

K.M. Bertsch, T. Voisin, J.B. Forien, E. Tiferet, Y.I. Ganor, M. Chonin, Y.M. Wang, M.J. Matthews, Critical differences between electron beam melted and selective laser melted Ti-6Al-4V. Mater. Des. 216, 110533 (2022). https://doi.org/10.1016/j.matdes.2022.110533

T. Mukherjee, T. DebRoy, Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Processes. 36, 442–449 (2018). https://doi.org/10.1016/j.jmapro.2018.10.028

J.V. Gordon, S.P. Narra, R.W. Cunningham, H. Liu, H. Chen, R.M. Suter, J.L. Beuth, A.D. Rollett, Defect structure process maps for laser powder bed fusion additive manufacturing. Addit. Manuf. 36, 101552 (2020). https://doi.org/10.1016/j.addma.2020.101552

J.C. Hastie, M.E. Kartal, L.N. Carter, M.M. Attallah, D.M. Mulvihill, Classifying shape of internal pores within AlSi10Mg alloy manufactured by laser powder bed fusion using 3D X-ray micro computed tomography: Influence of processing parameters and heat treatment. Mater. Charact. 163, 110225 (2020). https://doi.org/10.1016/j.matchar.2020.110225

E. Liverani, S. Toschi, L. Ceschini, A. Fortunato, Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 249, 255–263 (2017). https://doi.org/10.1016/j.jmatprotec.2017.05.042

M.L. Montero-Sistiaga, M. Godino-Martinez, K. Boschmans, J.-P. Kruth, J. Van Humbeeck, K. Vanmeensel, Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting). Addit. Manuf. 23, 402–410 (2018). https://doi.org/10.1016/j.addma.2018.08.028

A. Röttger, J. Boes, W. Theisen, M. Thiele, C. Esen, A. Edelmann, R. Hellmann, Microstructure and mechanical properties of 316L austenitic stainless steel processed by different SLM devices. Int. J. Adv. Manuf. Technol. 108(3), 769–783 (2020). https://doi.org/10.1007/s00170-020-05371-1

H. Irrinki, M. Dexter, B. Barmore, R. Enneti, S. Pasebani, S. Badwe, J. Stitzel, R. Malhotra, S.V. Atre, Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17–4 PH stainless steel. JOM. 68(3), 860–868 (2016). https://doi.org/10.1007/s11837-015-1770-4

C. Kamath, B. El-Dasher, G.F. Gallegos, W.E. King, A. Sisto, Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 74(1–4), 65–78 (2014). https://doi.org/10.1007/s00170-014-5954-9

A.B. Spierings, T.L. Starr, K. Wegener, Fatigue performance of additive manufactured metallic parts. Rapid Prototyping J. 19(2), 88–94 (2013). https://doi.org/10.1108/13552541311302932

A. Yadollahi, N. Shamsaei, Additive manufacturing of fatigue resistant materials: challenges and opportunities (in English). Int. J. Fatigue. 98, 14–31 (2017). https://doi.org/10.1016/j.ijfatigue.2017.01.001

A. Fatemi, R. Molaei, S. Sharifimehr, N. Phan, N. Shamsaei, Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int. J. Fatigue. 100, 347–366 (2017). https://doi.org/10.1016/j.ijfatigue.2017.03.044

M. Tang, P.C. Pistorius, Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue. 94, 192–201 (2017). https://doi.org/10.1016/j.ijfatigue.2016.06.002

V.-D. Le, E. Pessard, F. Morel, S. Prigent, Fatigue behaviour of additively manufactured Ti-6Al-4V alloy: the role of defects on scatter and statistical size effect. Int. J. Fatigue. 140, 105811 (2020). https://doi.org/10.1016/j.ijfatigue.2020.105811

Y. Liu, Y. Yang, D. Wang, A study on the residual stress during selective laser melting (SLM) of metallic powder. Int. J. Adv. Manuf. Technol. 87(1–4), 647–656 (2016). https://doi.org/10.1007/s00170-016-8466-y

Y. Murakami, T. Takagi, K. Wada, H. Matsunaga, Essential structure of S-N curve: Prediction of fatigue life and fatigue limit of defective materials and nature of scatter. Int. J. Fatigue. (2021). https://doi.org/10.1016/j.ijfatigue.2020.106138

R. Shrestha, J. Simsiriwong, N. Shamsaei, Fatigue behavior of additive manufactured 316L stainless steel under axial versus rotating-bending loading: Synergistic effects of stress gradient, surface roughness, and volumetric defects. Int. J. Fatigue. (2021). https://doi.org/10.1016/j.ijfatigue.2020.106063

E. Akgun, X. Zhang, T. Lowe, Y. Zhang, M. Doré, Fatigue of laser powder-bed fusion additive manufactured Ti-6Al-4V in presence of process-induced porosity defects. Eng. Fract. Mech. 259, 108140 (2022). https://doi.org/10.1016/j.engfracmech.2021.108140

C. Gautrelet, L. Khalij, M.R. Machado, Resonance track-and-dwell testing for crack length measurement on 304L stainless steel. Mech. Ind. 21(6), 617 (2020). https://doi.org/10.1051/meca/2020089

F. Wang, S. Krause, J. Hug, C. Rembe, A contactless laser doppler strain sensor for fatigue testing with resonance-testing machine (in English). Sensors (Basel, Switzerland). (2021). https://doi.org/10.3390/s21010319

M. Benedetti, V. Fontanari, M. Bandini, F. Zanini, S. Carmignato, Low- and high-cycle fatigue resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: mean stress and defect sensitivity. Int. J. Fatigue. 107, 96–109 (2018). https://doi.org/10.1016/j.ijfatigue.2017.10.021

V.U. Kumaran, A.S. Cebrian, C. Gschnitzer-Bärnthaler, M. Zogg, L. Weiss, K. Wegener, Utilization of CRFP in high-speed stamping presses and its gigacycle fatigue testing at resonance frequency. Int. J. Autom. Technol. 14(2), 15 (2020). https://doi.org/10.20965/ijat.2020.p0311

H.G. Lee, J.S. Park, Optimization of resonance-type fatigue testing for a full-scale wind turbine blade. Wind Energy. 19(2), 371–380 (2016). https://doi.org/10.1002/we.1837

S. Chowdhury, N. Yadaiah, C. Prakash, S. Ramakrishna, S. Dixit, L.R. Gupta, D. Buddhi, Laser powder bed fusion: a state-of-the-art review of the technology, materials, properties & defects, and numerical modelling. J. Mater. Res. Technol. 20, 2109–2172 (2022). https://doi.org/10.1016/j.jmrt.2022.07.121

H. Zhang, M. Xu, Z. Liu, C. Li, P. Kumar, Z. Liu, Y. Zhang, Microstructure, surface quality, residual stress, fatigue behavior and damage mechanisms of selective laser melted 304L stainless steel considering building direction. Addit. Manuf. 46, 102147 (2021). https://doi.org/10.1016/j.addma.2021.102147

Standard practice for conducting force controlled constant amplitude axial fatigue tests of metallic materials, ASTM-E466-21, ASTM International, 2021.

Q.G. Wang, P.E. Jones, Prediction of fatigue performance in aluminum shape castings containing defects. Metall. Mater. Trans. B. 38(4), 615–621 (2007). https://doi.org/10.1007/s11663-007-9051-4

Y. Murakami, H. Usuki, Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels. II: Fatigue limit evaluation based on statistics for extreme values of inclusion size. Int. J. Fatigue. 11(5), 299–307 (1989)

H. Masuo, Y. Tanaka, S. Morokoshi, H. Yagura, T. Uchida, Y. Yamamoto, Y. Murakami, Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue. 117, 163–179 (2018). https://doi.org/10.1016/j.ijfatigue.2018.07.020

Y. Yamashita, T. Murakami, R. Mihara, M. Okada, Y. Murakami, Defect analysis and fatigue design basis for Ni-based superalloy 718 manufactured by selective laser melting. Int. J. Fatigue. 117, 485–495 (2018). https://doi.org/10.1016/j.ijfatigue.2018.08.002

S. Romano, A. Brandão, J. Gumpinger, M. Gschweitl, S. Beretta, Qualification of AM parts: extreme value statistics applied to tomographic measurements. Mater. Des. 131, 32–48 (2017). https://doi.org/10.1016/j.matdes.2017.05.091

Y.N. Hu, S.C. Wu, Z.K. Wu, X.L. Zhong, S. Ahmed, S. Karabal, X.H. Xiao, H.O. Zhang, P.J. Withers, A new approach to correlate the defect population with the fatigue life of selective laser melted Ti-6Al-4V alloy. Int. J. Fatigue. 136, 105584 (2020). https://doi.org/10.1016/j.ijfatigue.2020.105584

A.A. Deev, P.A. Kuznetcov, S.N. Petrov, Anisotropy of mechanical properties and its correlation with the structure of the stainless steel 316L produced by the SLM method. Phys. Procedia. 83, 789–796 (2016). https://doi.org/10.1016/j.phpro.2016.08.081

Y. Hong, C. Zhou, Y. Zheng, L. Zhang, J. Zheng, The cellular boundary with high density of dislocations governed the strengthening mechanism in selective laser melted 316L stainless steel. Mater. Sci. Eng. A. 799, 140279 (2021). https://doi.org/10.1016/j.msea.2020.140279

O.O. Salman, C. Gammer, A.K. Chaubey, J. Eckert, S. Scudino, Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A. 748, 205–212 (2019). https://doi.org/10.1016/j.msea.2019.01.110

S.A. Grammatikos, E.Z. Kordatos, T.E. Matikas, A.S. Paipetis, Real-time debonding monitoring of composite repaired materials via electrical, acoustic, and thermographic methods. J. Mater. Eng. Perform. 23(1), 169–180 (2014). https://doi.org/10.1007/s11665-013-0672-2

M.M. Parvez, Y. Chen, S. Karnati, C. Coward, J.W. Newkirk, F. Liou, A displacement controlled fatigue test method for additively manufactured materials. Appl. Sci. 9(16), 3226 (2019). https://doi.org/10.3390/app9163226

T.C. Henry, F.R. Phillips, D.P. Cole, E. Garboczi, R.A. Haynes, T. Johnson, In situ fatigue monitoring investigation of additively manufactured maraging steel. Int. J. Adv. Manuf. Technol. 107(7–8), 3499–3510 (2020). https://doi.org/10.1007/s00170-020-05255-4

Y. Murakami, S. Beretta, Small defects and inhomogeneities in fatigue strength: experiments, models, and statistical implications. Extremes. 2(2), 123–147 (1999). https://doi.org/10.1023/a:1009976418553

P. Kousoulas, Y.B. Guo, On the probabilistic prediction for extreme geometrical defects induced by laser-based powder bed fusion. CIRP J. Manuf. Sci. Technol. 41, 124–134 (2023). https://doi.org/10.1016/j.cirpj.2022.11.024

Y. Murakami, Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions (Elsevier Science Ltd., New York, 2002), p.369

Y. AbouelNour, N. Gupta, In-situ monitoring of sub-surface and internal defects in additive manufacturing: a review. Mater. Des. 222, 111063 (2022). https://doi.org/10.1016/j.matdes.2022.111063

N. Sanaei, A. Fatemi, Analysis of the effect of internal defects on fatigue performance of additive manufactured metals. Mater. Sci. Eng. A. 785, 139385 (2020). https://doi.org/10.1016/j.msea.2020.139385

Č Donik, J. Kraner, I. Paulin, M. Godec, Influence of the energy density for selective laser melting on the microstructure and mechanical properties of stainless steel. Metals. 10(7), 919 (2020). https://doi.org/10.3390/met10070919

Acknowledgments

The authors would like to thank the financial support of the National Science Foundation grant CMMI-2152908.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kousoulas, P., Guo, Y.B. Process Signature for Porosity-Dominant Fatigue Scattering of Materials Processed by Laser Fusion. J Fail. Anal. and Preven. 23, 2075–2089 (2023). https://doi.org/10.1007/s11668-023-01741-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01741-5