Abstract

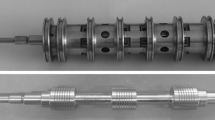

Cryogenic engine of satellite launch vehicle employs separation pyrovalves which are pyrotechnically actuated devices used for opening/closing of the flow of fluids. In the qualification test, pyrovalve withstood the functional test. However, during the post-fire acceptance test, one unit of the separation pyrovalve indicated leakage at 38 bar against specified 170 bar pressure. The leaked actuator diaphragm was investigated for identifying the reason for leakage. Leakage during post-fire acceptance test is attributed to the through-thickness hole formation on the AISI 321 stainless-steel diaphragm. Hole formation in diaphragm is caused by the impingement of molten zirconia from the combustion products of zirconium/potassium perchlorate (ZPP) charge to the diaphragm during firing operation. It was responsible for localized melting of stainless steel. After the formation of through-thickness hole on the diaphragm, the molten mixture got solidified and filled the through hole completely. During the post-fire acceptance test, the molten and solidified mixture got dislodged at 38 bar pneumatic pressure and resulted in leakage. Analysis is validated through thermal modelling and simulation, where observations are found to be matching. Estimation of combustion product required for the formation of through thickness hole of the observed dimension has also been estimated.

Similar content being viewed by others

References

J. Sachdev, A. Hosangadi, J. Chenoweth R.S. McDougle, Failure mode analysis of V-Shaped pyrotechnically actuated valves. 48th AIAA/ASME/SAE/ASEE Jt Propuls Conf Exhib (2012)

R. Saulsberry, J. Ramirez, H. Julien, M. Hart, W. Smith LB and NM, WSTF propulsion and pyrotechnics corrective action test program status—2000. in 35th Intersoc Energy Convers Eng Conf Exhib (2012)

G. Keller, N. Dybro, J. Raines, and J. Sikorski, Valve controlled automotive pyrotechnic systems. U.S. Patent 5,947,514, issued September 7, (1999)

J. Wang, L. Li, P. Wang, G. Hang, C. Zhou, Normally closed one-shot isolation valve for micropropulsion systems. Aerosp. Sci. Technol. 110, 106520 (2021)

S.K. Manwatkar, K. Jalaja, M.S. Dhanya, S.V.S. Narayana Murty, D. Sivakumar, B. Pant, M. Mohan, Metallurgical failure analysis of non-separation of isolation pyro valve used in space applications. Eng. Fail. Anal. 126, 105469 (2021)

D.-H. Hwang, D.-H. Han, J.-H. Han, H.-G. Sung, B.-T. Ryu, Separation behavior of pyrotechnically actuated device considering small-volume effect of combustion chamber. J. Spacecr. Rocket. 57(4), 823–834 (2020)

P.L. Varghese, Investigation of heat transfer in zirconium potassium perchlorate at low temperature: a study of the failure mechanism of the NASA standard initiator (No. NAS 1.26: 184774) (1989)

Material Properties at Low Temperatures. P. Duthil, Institut de Physique Nucléaire d’Orsay, IN2P3-CNRS/Université de Paris Sud, Orsay, France

P.F. Manicone, P.R. Iommetti, L. Raffaelli, An overview of zirconia ceramics: basic properties and clinical applications. J. Dentistry. 35(11), 819–826 (2007)

W.F. Smith, Structure and properties of engineering alloys (McGraw Hill, New York, 1981), p.296–299

Acknowledgment

The authors wish to place on record their deep sense of gratitude to Ignition Systems and Mechanism Group for referring the problem and providing the specimens for the analysis. The authors are grateful to Director, VSSC, for permitting to publish this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Manwatkar, S.K., Jalaja, K., Gupta, R.K. et al. Investigation of Leakage Observed in AISI 321 Stainless Steel Separation Pyro Valve During Post-Function Acceptance Test. J Fail. Anal. and Preven. 23, 1789–1802 (2023). https://doi.org/10.1007/s11668-023-01728-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01728-2