Abstract

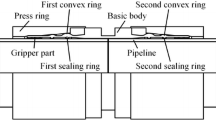

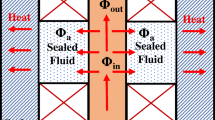

A new type of sealing device is designed for the temporary venting and nitrogen injection of the natural gas long-distance pipeline station under the current emergency condition. The finite element analysis and laboratory test of the device are carried out, and the results of the two are compared and analyzed; furthermore, to meet the higher bearing pressure requirements, the device was structurally improved and again subjected to finite element analysis. The above results show that the pressure-bearing capacity of the designed sealing device can reach 5 MPa, which meets the field work requirements; after the improvement, the von Mises stress of the O-ring is evenly distributed, and the value is only 36% of that before the improvement, while the contact stress is 181% of that before the improvement, and the sealing performance of the O-ring is enhanced.

Similar content being viewed by others

References

D.Z. Zeng, Q.Y. He, J.Y. Hu, Corrosion mechanism of hydrogenated nitrile butadiene rubber O-ring under simulated wellbore conditions. Corros. Sci. 107, 145–154 (2016)

K. Anjia, J. Matthias, P. Payam, Analysis of O-ring seal failure under static conditions and determination of end-of-lifetime criterion. Polymer. 11(8), 1251 (2019)

B.L. Liang, X. Yang, Z.L. Wang, Influence of randomness in rubber parameters on the reliability of rubber O-ring seal. Materials. 12(9), 1566 (2019)

P. Zadrapa, J. Malac, P. Konecny, Filler and mobility of rubber matrix molecules. Polym. Bull. 67(5), 927–936 (2011)

S. Spiridon, S. Benjimin, W. Chrustopher, Method for the evaluation of elastomeric seals by compression stress relaxation. Polym. Test. 32(8), 1299–1305 (2013)

Y. Eduardo, M.P. Nicola, R. Julien, Characterising the friction coefficient between rubber O-rings and a rigid surface under extreme pressures. Polym. Test. 104, 107378 (2021)

C.L. Zhou, J.Y. Zheng, C.H. Gu, Sealing performance analysis of rubber O-ring in high-pressure gaseous hydrogen based on finite element method. Int. J. Hydrog. Energy. 42(16), 11996–12004 (2017)

H.N. Jeong, S.H. Jai, C.S. Dong, A study on the behaviors and stresses of O-ring under uniform squeeze rates and internal pressure by transparent type photoelastic experiment. J. Mech. Sci. Technol. 25(9), 2427–2438 (2011)

K. Lingerkar, M.M. Khonsari, On the effects of sliding velocity and operating pressure differential in rotary O-ring seals. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 224(7), 679–657 (2010)

L. Baopeng, S. Bo, Y. Meichen, Time-variant reliability analysis for rubber O-ring seal considering both material degradation and random load. Materials. 10(10), 1211 (2017)

D. Wu, S.P. Wang, X.J. Wang, A novel stress distribution analytical model of O-ring seals under different properties of materials. J. Mech. Sci. Technol. 31(1), 289–296 (2017)

J. Hawong, J. Nam, S. Han, O. Kwon, S. Park, A study on the analysis of O-ring under uniform squeeze rate and internal pressure by photoelastic experimental hybrid method. J. Mech. Sci. Technol. 23(8), 2330–2340 (2009)

J. Nam, J. Hawong, S. Han, S. Park, Contact stress of O-ring under uniform squeeze rate by photoelastic experimental hybrid method. J. Mech. Sci. Technol. 22(12), 2337–2349 (2008)

S.H. Chen, G.Z. Jiang, G.F. Li, L.X. Xie, W.Q. Qian, Nonlinear analysis of rotary sealing performance of rubber O-ring. Mech. Eng. Mater. Sci. Civil Eng. II. 470, 371–375 (2014)

H.S. Lim, J.S. Hawong, D.C. Shin, A.O. Bernard, K.H. Lee, A study on the behaviors of the D-ring with a curvature radius using the photoelastic experimental hybrid method. J. Mech. Sci. Technol. 29(8), 3395–3404 (2015)

Y. Chen, G.P. Xiao, W.J. Zhong, Investigation of mechanical numerical simulation and expansion experiment of expandable liner hanger in oil and gas completion. Shock Vib. 2020, 1–13 (2020)

E. Liu, L. Lv, Q. Ma, Steady-state optimization operation of the west–east gas pipeline. Adv. Mech. Eng. 11(1), 1–14 (2019)

S.P. Lee, K.W. Kang, Deformation analysis of rubber seal assembly considering uncertainties in mechanical properties. J. Mech. Sci. Technol. 33(7), 3345–3353 (2019)

Z. Jie, X. Jingxuan, Investigation of static and dynamic seal performances of a rubber O-ring. J. Tribol. 140(4), 042202 (2018)

J. Zhang, C.J. Han, Z. Liang, Physics of failure analysis of power section assembly for positive displacement motor. J. Loss Prev. Process Ind. 44, 414–423 (2016)

Z. Xiaodong, Y. Lin, Z. Yi, Finite element analysis of tooth-shape combined seal ring based on fluid pressure penetration. Lubr. Eng. 44(12), 12–17 (2019)

H. Chuanjun, H. Yang, Z. Jie, Mechanical properties analysis and structure improvement of tooth and sliding ring combined seals. Lubr. Eng. 43(11), 86–92 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Huang, X., Tan, J. et al. Sealing Performance Analysis of Natural Gas Pipeline Venting and Nitrogen Injection Device Based on Numerical Simulation and Experiment. J Fail. Anal. and Preven. 23, 1171–1184 (2023). https://doi.org/10.1007/s11668-023-01654-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01654-3