Abstract

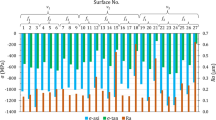

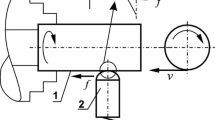

To investigate the effect of the slide diamond burnishing process on the mechanical properties of GCR15 steel, an experimental study was carried out. For this purpose, burnished and unburnished specimens have been prepared and compared in fatigue performance, surface roughness, microhardness, and SEM analysis. The burnishing process was carried out at a speed of 560 rpm, a burnishing force of 10 Kgf, a feed rate of 0.074 mm/rev and several passes of 3. Rotary bending fatigue tests were performed on the burnished and unburnished specimens, S–N curves were plotted from a maximum load representing 66% of tensile strength. The findings indicate that the fatigue strength was increased by up to 36% because of slide diamond burnishing compared to the non-burnished case. At lower stress levels, the improvement in fatigue strength is clearly observed. The fatigue curves reveal a slight reduction in the fatigue strength results compared to those reported in the literature, which can be attributed to the specimen's small shoulder fillet value.

Similar content being viewed by others

Abbreviations

- A% :

-

Ultimate elongation (%)

- f :

-

Burnishing feed rate (mm.rev−1)

- n:

-

Burnishing velocity (rev.min−1)

- Hv :

-

Surface Vickers hardness

- R:

-

Fatigue ratio σmin/σmax

- i :

-

Number of burnishing tool passes

- σ N :

-

Fatigue strength

- P y :

-

Burnishing force (Kgf)

- N:

-

Number of cycles

- r :

-

Burnishing ball radius (mm)

- σ D :

-

Endurance limit (MPa)

- Ra :

-

Arithmetic mean roughness (μm)

- σ a :

-

Stress amplitude (MPa)

- Ra B :

-

Burnishing arithmetic mean deviation

- SDB:

-

Slide diamond burnishing

- HVB :

-

Burnishing surface Vickers hardness

- BB:

-

Ball-burnishing

- AISI:

-

American Iron and Steel Institute

- M:

-

Unburnished specimens

- Rp 0,2 :

-

Yield strength (MPa)

- SDBS :

-

Slide diamond burnished specimens

- Rm :

-

Tensile strength (MPa)

- SEM:

-

Scanning electron microscopy

References

J. Maximov, G. Duncheva, A. Anchev, V. Dunchev, J. Capek, A cost-effective optimization approach for improving the fatigue strength of diamond-burnished steel components. J. Braz. Soc. Mech. Sci. Eng. 43(1), 1–13 (2021). https://doi.org/10.1007/s40430-020-02723-6

H. Hamadache, A. Amirat, K. Chaoui, Effect of diamond ball burnishing on surface characteristics and fatigue strength of XC55 steel. Int. Rev. Mech. Eng. 2(1), 40–48 (2008). https://doi.org/10.15866/irece.v6i6.8201

L.L. De Lacalle, A. Lamikiz, J. Muñoa, J. Sánchez, Quality improvement of ball-end milled sculptured surfaces by ball burnishing. Int J Mach Tool Manu. 45(15), 1659–1668 (2005). https://doi.org/10.1016/j.ijmachtools.2005.03.007

A.S. Robles, J.Á.D. De la Peña, A.D.J.B. García, E.A. Gómez, H.P. Mora, N.S. Robles, The ball burnishing process: state of the art of a developing technology. DYNA. 92(1), 28–33 (2017). https://doi.org/10.6036/7916

H. Hamadache, W. Taamallah, Z. Zahia, Characterization layers hardened burnished steel AISI/SAE 3115. Int. J. Mech. Appl. 4, 13–19 (2014). https://doi.org/10.5923/j.mechanics.20140401.03

Y. Takada, H. Sasahara, Effect of tip shape of frictional stir burnishing tool on processed layer’s hardness, residual stress and surface roughness. Coatings. 8(1), 32 (2018). https://doi.org/10.3390/coatings8010032

J.T. Maximov, G.V. Duncheva, A.P. Anchev, M.D. Ichkova, Slide burnishing—review and prospects. Int. J. Adv. Manuf. Technol. 104(1), 785–801 (2019). https://doi.org/10.1007/s00170-019-03881-1

J. Kalisz, K. Żak, S. Wojciechowski, M.K. Gupta, G.M. Krolczyk, Technological and tribological aspects of milling-burnishing process of complex surfaces. Tribol. Int. 155, 106770 (2021). https://doi.org/10.1016/j.triboint.2020.106770

S. Świrad, D. Wydrzynski, P. Nieslony, G.M. Królczyk, Influence of hydrostatic burnishing strategy on the surface topography of martensitic steel. Measure. 138, 590–601 (2019). https://doi.org/10.1016/j.triboint.2020.106770

D. Toboła, J. Morgiel, Ł Maj, TEM analysis of surface layer of Ti–6Al–4V ELI alloy after slide burnishing and low-temperature gas nitriding. Appl. Surf. Sci. 515, 145942 (2020). https://doi.org/10.1016/j.apsusc.2020.145942

A. Rodríguez, L.N. López de Lacalle, A. Celaya, A. Lamikiz, J. Albizuri, Surface improvement of shafts by the deep ball-burnishing technique. Surf. Coat. Technol. 206(11), 2817–2824 (2012). https://doi.org/10.1016/j.surfcoat.2011.11.045

V. Chomienne, F. Valiorgue, J. Rech, C. Verdu, Influence of ball burnishing on residual stress profile of a 15–5PH stainless steel. CIRP J. Manuf. Sci. Technol. 13, 90–96 (2016). https://doi.org/10.1016/j.cirpj.2015.12.003

R. Jerez-Mesa, G. Fargas, J.J. Roa, J. Llumà, J.A. Travieso-Rodriguez, Superficial effects of ball burnishing on trip steel AISI 301ln sheets. Metals. 11(1), 82 (2021). https://doi.org/10.3390/met11010082

A.A. García-Granada, G. Gomez-Gras, R. Jerez-Mesa, J.A. Travieso-Rodriguez, G. Reyes, Ball-burnishing effect on deep residual stress on AISI 1038 and AA2017-T4. Mater. Manuf. Processes. 32(11), 1279–1289 (2017). https://doi.org/10.1080/10426914.2017.1317351

R. Sadeler, M. Akbulut, S. Atasoy, Influence of mechanical (ball burnishing) surface treatment on fatigue behaviour of AISI 1045 steel. Kovove Materialy. 51(1), 31–35 (2013). https://doi.org/10.4149/km_2013_1_31

R. Avilés, J. Albizuri, A. Rodríguez, L.L. De Lacalle, Influence of low-plasticity ball burnishing on the high-cycle fatigue strength of medium carbon AISI 1045 steel. Int. J. Fatigue. 55, 230–244 (2013). https://doi.org/10.1016/j.ijfatigue.2013.06.024

J.A. Travieso-Rodríguez, R. Jerez-Mesa, G. Gómez-Gras, J. Llumà-Fuentes, O. Casadesús-Farràs, M. Madueño-Guerrero, Hardening effect and fatigue behavior enhancement through ball burnishing on AISI 1038. J. Market. Res. 8(6), 5639–5646 (2019). https://doi.org/10.1016/j.jmrt.2019.09.032

N. Jouini, P. Revel, G. Thoquenne, Investigation of surface integrity induced by various finishing processes of AISI 52100 bearing rings. Materials. 15(10), 3710 (2022). https://doi.org/10.3390/ma15103710

A. Panda, A.K. Sahoo, R. Kumar, R.K. Das, A review on machinability aspects for AISI 52100 bearing steel. Mater. Today Proc. 23, 617–621 (2020). https://doi.org/10.1016/j.matpr.2019.05.422

C.D. Aquino, L.G. Rodrigues, J.M. Branco, W.J.S. Gomes, Statistical correlation investigation of a single-doweled timber-to-timber joint. Eng. Struct. 269, 114810 (2022). https://doi.org/10.1016/j.engstruct.2022.114810

L. Luca, S. Neagu-Ventzel, I. Marinescu, Effects of working parameters on surface finish in ball-burnishing of hardened steels. Precis. Eng. 29(2), 253–256 (2005). https://doi.org/10.1016/j.precisioneng.2004.02.002

N. Loh, S. Tam, Effects of ball burnishing parameters on surface finish—a literature survey and discussion. Precis. Eng. 10(4), 215–220 (1988). https://doi.org/10.1016/0141-6359(88)90056-6

P. Puerto, R. Fernández, J. Madariaga, J. Arana, I. Gallego, Evolution of surface roughness in grinding and its relationship with the dressing parameters and the radial wear. Procedia Eng. 63, 174–182 (2013). https://doi.org/10.1016/j.proeng.2013.08.181

R. Fernández, A. Iriarte, P. Puerto, I. Gallego, P. Arrazola, Analysis of the behavior of grinding wheels in surface grinding. AIP Conf. Proc. Am. Inst. Phys. 1, 374–382 (2012). https://doi.org/10.1063/1.4707586

E. Yagyaev, Stabilization of processing quality parameters at cylindrical external grinding by control of the rotational frequency of the grinding wheel. Mater. Today Proc. 38, 1882–1885 (2021). https://doi.org/10.1016/j.matpr.2020.08.569

F. Jasso Lucio The Effects of Roller Burnishing Parameters Upon Surface Properties of AISI 52100 Bearing Steel (60HRC). A Finite Element Analysis-Edición Única.

M. Bourebia, L. Laouar, H. Hamadache, S. Dominiak, Improvement of surface finish by ball burnishing: approach by fractal dimension. Surf. Eng. 33(4), 255–262 (2017). https://doi.org/10.1080/02670844.2016.1232778

R. McClung, A literature survey on the stability and significance of residual stresses during fatigue. Fatigue Fract. Eng. Mater. Struct. 30(3), 173–205 (2007). https://doi.org/10.1111/j.1460-2695.2007.01102.x

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taamallah, O., Hamadache, H., Mokas, N. et al. Investigation of the Effects of Slide Diamond Burnishing Process on the Mechanical Performance of GCr15 Steel. J Fail. Anal. and Preven. 23, 1101–1113 (2023). https://doi.org/10.1007/s11668-023-01652-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01652-5