Abstract

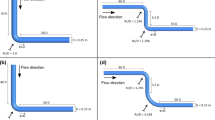

In this paper, the erosion performance of a new normally open arrow-type check valve spool was studied by the CFD method. The liquid phase is regarded as a continuous phase, and the particles are solved by a discrete phase model. Based on the verified numerical model, the effect law of five key factors, such as sealing surface Angle α/2, β/2, and particle mass flow rate, on the erosion of the valve spool sealing surface (VSSS) was studied. The maximum erosion rate of the VSSS is used as the evaluation index. The results show that the lower end of the sealing surface is the area with the most serious erosion damage to the VSSS, and the damage degree increases with the increase of α/2. In addition, the maximum erosion rate of the VSSS increases with the increase in particle mass flow and particle diameter and decreases with the increase in fluid viscosity. In terms of structure, reducing the sealing surface angle α/2 can reduce the erosion damage to the VSSS.

Similar content being viewed by others

References

X.D. Zhang, Y.S. Chen, W.W. Yang, Erosion of an arrow-type check valve duo to liquid-solid flow based on computational fluid dynamics. J. Fail. Anal. Prev. 19(02), 570–580 (2019)

L. Chen. Design and Performance Study of a New Type of Internal Blowout Preventer. (Southwest Petroleum University, 2019). pp. 1–2. (in Chinese)

K. Wang, X.D. Zhang, Y.F. Li et al., Research on fuzzy reliability approach in view of arrow-type check valves. Mach. Des. Res. 31(06), 127–130 (2015). ((in Chinese))

L. Luo, P. Hu, C. He, Research and application of new arrow check valve. Drilling Prod Technol. 38(06), 64–65 (2015). ((in Chinese))

C.J. Gao, J.H. Zheng, Y.H. Jing et al., Development and application of full-diameter inside blowout preventer. Drill. Prod. Technol. 34(06), 65–67 (2011). ((in Chinese))

H. Chen, C.J. Wang, Z. Wu et al., Working mechanism and failure analysis of check valves of BOP (blowout preventer) system in drilling string for safe drilling. Nat. Gas. Ind. 30(06), 69–72 (2010). ((in Chinese))

B. Liu, Z. Jiangang, Q. Jianhua, Numerical study of solid particle erosion in butterfly valve. Mater. Sci. Eng. 220(1), 12018 (2017). ((in Chinese))

L. Nokleberg, T. Sontvedt, Erosion in choke valves—oil and gas industry applications. Wear. 186(02), 401–412 (1995)

L. Nokleberg, T. Sontvedt, Erosion of oil & gas industry choke valves using computational fluid dynamics and experiment. Int. J. Heat Fluid Flow. 19(06), 636–643 (1998)

B. Li, Q. Zhang, Erosion characteristics analysis for bypass valve of positive displacement motor based on CFD. Coal Eng. 49(07), 132–135 (2017). ((in Chinese))

Y.Q. Xu, Z.C. Guan, Y.W. Liu et al., Structural optimization of downhole float valve via computational fluid dynamics. Eng. Fail. Anal. 44, 85–94 (2014)

J. Tang, W. Jin, H.R. Yan, Structural design and experimental study of a new arrow clappet valve. Drill. Prod. Technol. 37(01), 81–83 (2014). ((in Chinese))

J.J. Jing, X. Tang, W.B. Chen et al., Study on erosion characteristics of elbow erosion of maniflod for relief pressure of high-yield natural gas well. Surf. Technol. 50(12), 329–339 (2021). ((in Chinese))

S.E. Kim, D. Choudhury, B. Patel, Computations of complex turbulent flows using the commercial code fluent. Model. Complex Turbul. Flows. 2, 259–276 (1999)

T.H. Shih, W.W. Liou, A. Shabbir et al., A new K-epsilon Eddy viscosity model for high reynolds number turbulent flows: model development and validation. Comput. Fluids. 3(24), 227–238 (1995)

H.Y. Liu, N. Wei, Study on erosion damage of solid particles to oil and gas well tubing. China Min. Mag. 27(2), 157–162 (2018). ((in Chinese))

Y.L. Zhang, B.S. McLaury, S.A. Shirazi, Improvements of particle near-wall velocity and erosion predictions using a commercial CFD code. J. Fluids Eng. 131(3), 31303 (2009)

J.Z. Guo, Y.H. Geng, Wearing characteristics study and structural optimization of butterfly valve under solid-liquid two-phase flow. Machinery. 57(3), 42–46 (2019). ((in Chinese))

G. Grant, W. Tabakoff, Erosion prediction in turbomachinery resulting from environmental solid particles. J. Aircr. 12(5), 471–478 (1975)

Y.B. Yin, J.H. Fu, Y.L. Jin, Numerical simulation of erosion wear of pre-stage of jet pipe servo valve. J. Zhejiang Univ. (Eng. Sci.). 49(12), 2252–2260 (2015). ((in Chinese))

D. Aquaro, E. Fontani, Erosion of ductile and brittle materials. Meccanica. 36, 651–661 (2001)

Acknowledgments

The research is supported by National Key Research and Development Program of China (2018YFC0310201)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, G., Wu, W., Xu, J. et al. Research on the Erosion Performance of a New Normally Open Arrow-Type Check Valve Spool. J Fail. Anal. and Preven. 22, 1725–1732 (2022). https://doi.org/10.1007/s11668-022-01467-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01467-w