Abstract

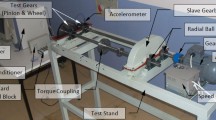

To improve the effectiveness of fault monitoring in mechanical systems, particularly rotary machinery, new technologies and methodologies have been developed in recent years. RMS, Kurtosis, and other global vibration indicators are widely used in the industrial sector and are also recommended by international standards. However, these parameters do not allow for a precise diagnosis of the equipment’s condition. In this paper, attempt is made to use guidelines of ISO 10816 for fault detection in gearboxes. A test rig is fabricated for a two-stage gearbox, which is connected to a disk break. A speed variation is provided by a one HP three phase induction motor. Speed range of 500, 1200 and 2100 rpm are selected for vibration monitoring. At a 40-h supervision periodicity, the load is increased from zero to 5 Kgf/cm2. The study considers a total of 5400 hours of gearbox performance. A total of 28 observations of velocity and 4 envelop acceleration is recorded. From the analysis, misalignment is observed on 26/06/18 and reach to gear failure on 20/08/18. After opening the gearbox, the gear near to input and output shaft is found damaged critically prolonged to gear teeth missing, i.e., broken teeth. Replacement of pair of gears and bearing is recommended.

Similar content being viewed by others

References

A. Jaiswal, K.S. Zakiuddin, V.V. Shukla, Fault diagnosis of gear by vibration analysis. Int. J. Latest Trends Eng. Technol. (IJLTET). 3(1), 26–32 (2013)

T Li, J Wen, T He, Z Liu, Wavelet analysis based on DSP gearbox vibration signal processing applications, International conference on electric information and control engineering, 2011

L Ziran, H Tao, J Guoxing, Analysis of wavelet envelope spectrum to vibration signal in the gearbox, International conference on electrical and control engineering, p. 3594 – 3596, 2010

W.J. Wang, P.D. McFadden, Application of wavelets to gearbox vibration signals for fault detection. J. Sound Vibration. 192(5), 816–828 (1996)

A. Aherwar, M.S. Khalid, Vibration analysis techniques for gearbox diagnostic: a review. Int. J. Adv. Eng. Technol. 3(2), 04–12 (2012)

G Jingwei, Z Peilin, L Baoyuan, X Zhengjun, An integrated fault diagnosis method of gearboxes using oil analysis and vibration analysis, The eighth international conference on electronic measurement and instruments, p. 3-371 to 3-374 (2007)

Y Feng, J Li, Y Qui, W Yang, D Infield, Study on order analysis for condition monitoring wind Turbine Gearbox, IET renewable power generation conference, Naples, Italy, p. 1–4, 2014

W Touti, M Salah, S B Salem, K Bacha, A Chaari, Spur gearbox mixed fault detection using vibration envelope and motor stator current signatures analysis, 17th international conference on Sciences and Techniques of Automatic control & computer engineering - STA'2016, Sousse, Tunisia, December 19-21, Pages 193–198, 2016

J. Kattelus, J. Miettinen, A. Lehtovaara, Detection of gear pitting failure progression with on-line particle monitoring. Tribol. Int. 118, 458–464 (2018)

D.F. Plöger, P. Zech, S. Rinderknecht, Vibration signature analysis of commodity planetary gearboxes. Mech. Syst. Signal Process. 119, 255–265 (2019)

T. Praveenkumar, B. Sabhrish, M. Saimurugan, K.I. Ramachandran, Pattern recognition based on-line vibration monitoring system for fault diagnosis of automobile gearbox. Measurement. 114, 233–242 (2018)

W Li, A Dadouche, J Liu, Frequency Analysis on Vibration Signatures for Gearbox Spalling Defect Detection. IEEE international conference on prognostics and health management (ICPHM), 2016

T.H. Loutas, D. Roulias, E. Pauly, V. Kostopoulos, The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Process. 25(4), 1339–1352 (2011)

S Li, D Jiang, M Zhao, Experimental investigation and analysis for gearbox fault. World Non-Grid-connected wind power and energy conference, 2010

H. Li, Y. Zhang, H. Zheng, Application of Hermitian wavelet to crack fault detection in gearbox. Mech. Syst. Signal Process. 25, 1353–1363 (2011)

S. Tong, Y. Huang, Y. Jiang, Y. Weng, Z. Tong, N. Tang, F. Cong, The identification of gearbox vibration using the meshing impacts-based demodulation technique. J. Sound Vibration. 461, 114879 (2019)

N. Barbieri, G.D.S.A.V. Barbieri, B.M. Martins, L.D.S.A.V. Barbieri, K.F. de Lima, Analysis of automotive gearbox faults using vibration signal. Mech. Syst. Signal Process. 129, 148–163 (2019)

Z.H.O.U. Min, W.A.N.G. Ke, W.A.N.G. Yang, L.U.O. Kaijia, F.U. Hongyong, S.I. Liang, Online condition diagnosis for a two-stage gearbox machinery of an aerospace utilization system using an ensemble multi-fault features indexing approach. Chin. J. Aeronaut. 32(5), 1100–1110 (2019)

X. Zhang, Q. Zhang, M. Chen, Y. Sun, X. Qin, H. Li, A two-stage feature selection and intelligent fault diagnosis method for rotating machinery using hybrid filter and wrapper method. Neurocomputing. 275, 2426–2439 (2018)

J. Wang, Yu. Shunming Li, Z.A. Xin, Gear fault intelligent diagnosis based on frequency domain feature extraction. J. Vib. Eng. Technol. 7, 159 (2019). https://doi.org/10.1007/s42417-019-00089-1

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gholap, A.B., Jaybhaye, M.D. Condition Monitoring of Two-Stage Spur Gearbox Using Vibration Signature Spectrum Analysis. J Fail. Anal. and Preven. 22, 1420–1430 (2022). https://doi.org/10.1007/s11668-022-01441-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01441-6