Abstract

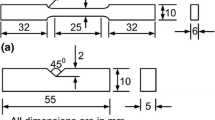

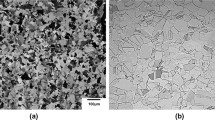

The space of irradiation surveillance capsules of nuclear power plants is limited. How to obtain the multiplicative toughness data of service materials based on these monitoring specimens is an important challenge in nuclear engineering. The reconstitution specimens could be reused to gain newer data or putted back into radiation monitoring tubes to gain highly irradiated material performance data for extended life operation of nuclear power plants. In this study, the Charpy V-notched impact test was carried out on the intact and reconstituted specimens of 30Mn2V steel by electron beam welding recombination technology, the multiplicative impact test data were obtained, and the relationship between impact energy of fracture with temperature was studied. The impact energy is converted into 1 T-CT equivalent fracture toughness, and then the reference temperature and master curve equation of 30Mn2V steel are calculated by the multi-temperature method. The consistency and dispersion of fracture toughness between reconstituted specimens and intact specimens are compared and studied. In this paper, the impact toughness data of materials are multiplied by specimens reconstitution technology, and the fracture toughness distribution in the ductile–brittle transition zone of the ferritic steel is predicted and evaluated.

Similar content being viewed by others

References

H. Xikou, L. Zhengdong, Z. Deli et al., Steel for nuclear pressure vessels in China and its manufacturing technology progress. Prog. Mater. China. 39(463), 509–518 (2020)

C. Wang, Z. Tong, W. Zhong et al., A method for directly measuring fracture toughness and determining reference temperature for RPV steels by Charpy impact test. Eng. Fract. Mech. 243, 107526 (2021)

M. Kolluri, P. ten Pierick, T. Bakker et al., Influence of N–Mn contents on the embrittlement of PWR RPV model steels irradiated to high fluences relevant for LTO beyond 60 years. J. Nucl. Mater. 55, 153036 (2021)

Z. Henghui, Z. Weihua, N. Guangsheng et al., The model predicts the effect of size effect on the fracture toughness of - steel. At. Energy Sci. Technol. 56(01), 186–192 (2022)

J. Wang, W. Qiang, C. Li et al., Study of the magnetization work of RPV steel in dependence on neutron irradiation. J. Magn. Magn. Mater. 537, 168239 (2021)

D.J.G. RaoMoJianbo et al., Research progress on toughness evaluation and ductile brittle transition mechanism of reactor pressure vessel steel. Mech. Eng. Mater. 45(07), 7–11 (2021)

M. Yu, Z. Luo, Y.J. Chao, Correlations between Charpy V-notch impact energy and fracture toughness of nuclear reactor pressure vessel (RPV) steels. Eng. Fract. Mech. 147, 187–202 (2015). https://doi.org/10.1016/j.engfracmech.2015.08.008

S. Cicero, M. Lambrecht, H. Swan et al., Fracture mechanics testing of irradiated RPV steels by means of sub-sized specimens: FRACTESUS project. Proc. Struct. Integr. 28, 61–66 (2020)

W. Qiangmao, W. Rongshan, S. Guogang et al., Analysis and research on life extension of PWR in the United States and key problems of life extension in China. Press. Vessel. 27(6), 46–51 (2010)

K. Wallin, P. Karjalainen-Roikonen, S. Pallaspuro, Low-temperature fracture toughness estimates for very high strength steels. Int. J. Offshore Polar Eng. 26(4), 33–338 (2016)

T. Meshii, Data-driven approach to construct a fracture toughness master curve for ferritic steels based on tensile properties. Fatigue Fract. Eng. Mater. Struct. 45(2), 617–619 (2022)

GB/T 229-2020 Metallic materials: Charpy pendulum impact test method (2020)

Q. Wan, R. Wang, G. Shu, Analysis method of Charpy V-notch impact data before and after electron beam welding reconstitution. Nucl. Eng. Des. 241(1), 459–463 (2011)

R. Chaouadi, R. Gerard, Development of a method for extracting fracture toughness from instrumented Charpy impact tests in the ductile and transition regimes. Theor. Appl. Fract. Mech. 115(1), 1–3 (2021)

ASTM E1921-2010: Standard test method for determination of reference temperature, to, for ferritic steels in the transition range. (2010).

Acknowledgments

This work has been supported by Fund projects: Zhejiang Basic Public Welfare Research Program (LGG20E010005, LY21E010001) and Youth Fund Project of Nuclear Industry College (QNJJ-2022-03). The authors would like to thank Professor Guo-gang Shu, China, United Heavy Gas Turbine Technology Co., Ltd, Professor Hui Ding, Southeast University, Professor Rong-shan Wang, Suzhou Nuclear Power Research Institute Co.,Ltd, and Professor Hui Lin, Professor Duan Wang, Nuclear Industry College, for their useful suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, Qm., Chen, Ls., Pang, Jj. et al. Study on Data Multiplication of Impact Toughness by Specimen Reconstitution Technique and Master Curve. J Fail. Anal. and Preven. 22, 1229–1235 (2022). https://doi.org/10.1007/s11668-022-01410-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01410-z