Abstract

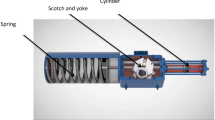

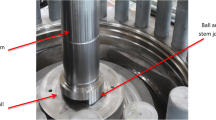

Valve failure is a big risk and a costly phenomenon in the offshore sector of the oil and gas industry. It results in severe negative consequences such as loss of asset; loss of production due to plant shutdown; health, safety and environmental (HSE) issues such as hydrocarbon (oil and gas) spillage; environmental pollution; and sometimes loss of human life. Different types of valve failures have occurred in the Norwegian offshore industry for various reasons such as poor material selection, corrosion, mechanical failure of valve components due to high stresses and loads, lack of coating and lack of inspection. The aim of this paper is to review and critique some of the wrong material selection approaches for industrial valves in the offshore sector of the oil and gas industry that lead to the corrosion and failure of valves, and to provide an appropriate material selection solution to mitigate these failures. Seven cases of material failures due to corrosion, including a valve gear box in coated cast iron, bolting made of low alloy steel with hot dip galvanized coating, a stem key made of a low alloy steel, stem material in 17-4 PH, spring material in Inconel X750, duplex, super duplex and hard nickel alloys in subsea as well as graphite packing in seawater, are reviewed, and preventive measures are proposed to avoid corrosion risk. In general, the use of carbon and low alloy steel for valves in the offshore environment should be limited and the use of corrosion-resistant alloys (CRAs) is proposed.

Similar content being viewed by others

References

Nesbitt Brian, Handbook of valves and actuators: valves manual international, 1st edn. (Elsevier, Oxford, 2007)

P. Smit, R.W. Zappe, Valve selection handbook, 5th edn. (Elsevier, New York, 2004)

K. Sotoodeh, Optimized valve stem design in oil and gas industry to minimize major failures. J. Fail. Anal. Prev. (2020). https://doi.org/10.1007/s11668-020-00891-0

K. Sotoodeh, Valve failures, analysis and solutions. Valve World 23(11), 48–52 (2018)

EDP Solutions, Offshore. [online] available at: http://www.exploration-production-services.de/en/o-offshore.html. Accessed: July 23, 2020 (2020)

B.A. Miller, Material selection for failure prevention. ASM International. Vol. 11 (2002). https://doi.org/10.31399/asm.hb.v11.9781627081801

G. Nustad, Tackling corrosive challenges in the oil and gas industry. Valve World 20(11), 56–60 (2015)

K. Sotoodeh, Requirement and calculation of corrosion allowance for piping and valves in oil and gas industry. J. Bio Tribo Corros. (2020). https://doi.org/10.1007/s40735-019-0319-4

R. Singh, Pipeline integrity management and risk evaluation. 2nd revision. Gulf Professional Publishing. Elsevier (2017)

K. Sotoodeh, Material selection for subsea valves. Stainless Steel World Magaz. 32, 47–50 (2020)

APV SPX (2008). Corrosion handbook. USA. NY

R.H. Perry, D.W. Green, Perry’s chemical engineers’ handbook, 9th edn. (McGraw Hill, New York, 2019)

Norsok. Materials selection. Norsok M-001, Rev.04. Lysaker. Norway (2004)

Norsok, Piping and valves. Norsok L-001, Rev.03. Lysaker. Norway (1999)

K. Sotoodeh, Standardization for coatings. Valve. World 23(3), 60–63 (2018)

Y. Bai, Q. Bai, Subsea engineering handbook, 1st edn. (Elsevier, Atlanta, 2012)

J. Marsh, G. Gibson, M. Walsh, Hydrogen embrittlement of corrosion resistant alloys under cathodic protection conditions. NACE international (2004)

M. Schofield, Plant engineer’s reference book, 2nd edn. (Elsevier, Amsterdam, 2003)

K. Sotoodeh, A review on process and valve technology. J. Marine Syst. Ocean Technol. 14, 210–219 (2019). https://doi.org/10.1007/s40868-019-00061-4

K. Sotoodeh, Analysis and improvement of material selection for process piping system in offshore industry. Am. J. Mech. Eng. 6(1), 17–26 (2018). https://doi.org/10.12691/ajme-6-1-3

K. Sotoodeh, Pipeline valves technology, material selection, welding, and stress analysis (a case study of a 30 in class 1500 pipeline ball valve). J. Pressure Vessel Technol. ASME. 140(4): 044001. PVT-18-1043 (2018). https://doi.org/10.1115/1.4040139

C. De Waard, U. Lotz, D.E. Milliams, Predictive model for CO2 corrosion engineering in wet natural gas pipelines. Corrosion 47(12), 976–985 (1991)

Iranian Petroleum Standard (IPS), Engineering standard for corrosion consideration in material selection. IPS-E-TP-740, Tehran, Iran (2008)

Norsok, CO2 corrosion rate calculation model. Norsok M-506, Rev.02. Lysaker. Norway (2005)

International Organization for Standardization (ISO), ISO 15156. Petroleum and natural gas industries-Metallic for use in H2S containing environments in oil and gas production. 3rd Edn. Genova, Switzerland (2015)

National association of corrosion engineers (NACE), NACE-MR0175. Standard material requirements-sulphide stress cracking resilient metallic materials for oilfield equipment. Huston-Texas-USA (2002)

Bujalski M., Actuators and controls, gearboxes 101. Valve Magazine. [online] available at: https://www.valvemagazine.com/magazine/sections/actuators-controls/9133-gearboxes-101.html (2018)

K. Sotoodeh, Actuator selection and sizing for valves. Nature Appl. Sci. 1, 1207 (2019). https://doi.org/10.1007/s42452-019-1248-z

P. Pedeferri, Galvanic corrosion (Engineering Materials. Springer, Cham, Corros. Sci. Eng., 2018). https://doi.org/10.1007/978-3-319-97625-9_10

American Petroleum Institute (API), Specification for pipeline valves. API 6D, 24th edn. (API, Washington, DC, 2014)

M.F. Aycan, Investigation on mechanical properties of AISI 4140 and AISI 4340 steels on various martensitic volume fractions. Conference paper. International scientific and vocational studies congress (2018)

W. Ming, Z. Zhihao, W. Xu, W. Chenchong, P. Liang, Corrosion behaviour of 17-4 PH stainless steel in simulated marine environment. Mater. Corros. (2018). https://doi.org/10.1002/maco.201810454

M.C. Fatah, A. Mills, A. Darwin, C. Selman, An overview of seabed storage methods for pipelines and other oil and gas equipment. Corros. Sci. Technol. 16(2), 76–84 (2017)

A. Bahrami, P. Woollin, Hydrogen induced stress cracking of duplex stainless-steel subsea components. TWI Ltd. Conference paper, Offshore Mechanics and Arctic Engineering (OMAE) conference, Shanghai, China (2010)

M. Solnordal, S. Wasberg, G. Heiberg, E. Odd, Hydrogen Induced Stress Cracking (HISC) and DNV-RP-F112 (Det Norske Veritas, Hovik, 2009)

Workshop agreement NORSOK M-WA-01, HISC guideline for duplex stainless steel. Revision 01. Lysaker, Norway: NORSOK (2005)

Det Norske Veritas (DNV) RP-F-112, Design of duplex stainless-steel subsea equipment exposed to cathodic protection. Hovik, Norway: Det Norske Veritas (2008)

K. Sotoodeh, Why are butterfly valves a good alternative to ball valves for utility services in the offshore industry? Am. J. Ind. Eng. 5(1), 36–40 (2018). https://doi.org/10.12691/ajie-5-1-6

American Petroleum Institute 609, Butterfly valves: Double flanged lug and wafer (6th ed.). Washington, DC: API (2004)

K. Sotoodeh, Butterfly valves application in the Norwegian offshore industry. Valve World 22(02), 63–64 (2017)

K. Sotoodeh, Packing solutions for butterfly valves in sea water services. Valve World magazine. 20(9), 48–53 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sotoodeh, K. A Review and Analysis of Industrial Valve Material Failures Due to Corrosion and Proposals for Prevention Measures Based on Industrial Experiences in the Offshore Sector of the Oil and Gas Industry. J Fail. Anal. and Preven. 21, 261–267 (2021). https://doi.org/10.1007/s11668-020-01064-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-01064-9