Abstract

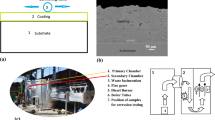

In the present work, Inconel-718 (IN718) coating was developed on a gray cast iron (C.I) substrate by utilizing a high-velocity oxy-fuel spray technique. The microstructural analysis was performed to know the topological characteristics of the deposited IN718 coating. Corrosion testing of bare and coated samples was carried out at an ambient temperature in a NaCl solution (3.5 wt.%) using potentiodynamic polarization technique. The kinetics of corrosion and surface characteristics of the as-sprayed and corroded coatings were studied by scanning electron microscopy/energy-dispersive spectroscopy techniques. The different phases in the feedstock powder and as-sprayed coating were determined through X-ray diffraction analysis. The reported average microhardness value of the developed IN718 coating was 563 ± 15 HV0.2. The increased hardness of the IN718 coating is credited to the existence of Mo and Ti elements in the IN718 coatings. Corrosion testing showed that the IN718 coating exhibited the maximum corrosion resistance compared to a C.I. substrate due to a stable passive layer in the IN718 specimen.

Graphic Abstract

Similar content being viewed by others

References

H. Vasudev, L. Thakur, A. Bansal, H. Singh, S. Zafar, High temperature oxidation and erosion behaviour of HVOF sprayed bi-layer alloy-718/NiCrAlY coating. Surf. Coat. Technol. 362, 366–380 (2019)

G. Prashar, H. Vasudev, Hot corrosion behavior of super alloys. Mater. Today Proc. 26, 1131–1135 (2020)

G. Prashar, H. Vasudev, L. Thakur, Performance of different coating materials against slurry erosion failures in hydrodynamic turbines: a review. Eng. Fail. Anal. (2020). https://doi.org/10.1016/j.engfailanal.2020.104622

J.L. Liu, G.Q. Shi, P.D. Ding, H.O. Ye, Z.X. Ou, Features of laser alloying of grey cast iron. Lasers Eng. 6(2), 81–101 (1997)

X. Cheng, S.B. Hu, W.L. Song, X.S. Xiong, Improvement in corrosion resistance of a nodular cast iron surface modified by plasma beam treatment. Appl. Surf. Sci. 286, 334–343 (2013)

Z. Lestan, M. Milfelner, J. Balic, M. Brezocnik, I. Karabegovic, Laser deposition of Metco 15E, Colmony 88 and VIM CRU 20 powders on cast iron and low carbon steel. Int. J. Adv. Manuf. Technol. 66(9–12), 2023–2028 (2013)

A.L. Maco, F.J. Belzunce, Laser surface hardening of gray cast irons. Rev. Metal. 34(2), 126–130 (1998)

V. Ozcelik, U. Oliveira, M. Boer, J.T.M. Hosson, Thick Co-based coating on cast iron by side laser cladding: analysis of processing conditions and coating properties. Surf. Coat. Technol. 201(12), 5875–5883 (2007)

F. Fernandes, A. Cavaleiro, A. Loureiro, Oxidation behavior of Ni-based coatings deposited by PTA on gray cast iron. Surf. Coat. Technol. 207, 196–203 (2012)

P. Fauchais, A. Vardelle, Thermal sprayed coatings used against corrosion and corrosive wear, in Advanced Plasma Spray Applications (InTech, 2012)

J. Yoganandh, S. Natarajan, S.P.K. Babu, Erosion behaviour of WC-Co-Cr thermal spray coated grey cast iron under mining environment. Trans. Indian Inst. Met. 66(4), 437–443 (2013)

S. Bouaricha, J.G. Legoux, B. R. Marple, Presented at ITSC 2005 Proc., Basel, Switzerland, May 2–4, 2005, pp. 981–985

M. Bjordal, E. Bardal, T. Rogne, T.G. Eggen, Erosion and corrosion properties of WC coatings and duplex stainless steel in sand containing synthetic sea water. Wear 186–187, 508–514 (1995)

M.M. Stack, T.M. Abd El-Badia, Some comments on mapping the combined effects of slurry concentration, impact velocity and electrochemical potential on the erosion-corrosion of WC/Co-Cr coatings. Wear 264, 826–837 (2008)

J. Vetter, G. Barbezat, J. Crummenauer, J. Avissar, Surface treatment selections for automotive applications. Surf. Coat. Technol. 200(5), 1962–1968 (2005)

H.M. Shalaby, S. Attari, W.T. Riad, V.K. Gouda, Erosion-corrosion behavior of some cast alloys in seawater. Corrosion 48, 206–217 (1992)

K. Sasaki, G.T. Burstein, Erosion-corrosion of stainless steel under impingement by a fluid jet. Corros. Sci. 49, 92–102 (2007)

C.H. Tang, F.T. Cheng, H.C. Man, Laser surface alloying of a marine propeller bronze using aluminium powder: part II: corrosion and erosion-corrosion synergism. Surf. Coat. Technol. 200, 2594–2601 (2006)

R.J.K. Wood, Y. Puget, K.R. Trethewey, K. Stokes, The performance of marine coatings and pipe materials under fluid-borne sand erosion. Wear 219, 46–59 (1998)

H. Yu, Y.G. Zheng, Z.M. Yao, The cavitation erosion and erosion-corrosion behavior of carbon steel in simulating solutions of three rivers of china. Mater. Corros. 57, 705–714 (2006)

I.G. Wright, B.A. Pint, Bond coating issues in thermal barrier coatings for industrial gasturbines. Proc. Inst. Mech. Eng. Part A J. Power Energy 219(A2), 101–107 (2005)

J. Prybylowski, R. Ballinger, Influence of microstructure on the environmentally assisted cracking of Inconel 718. NACE 43, 111–117 (1987)

O. Ozgun, R. Yilmaz, H.O. Gulsoy, F. Findik, The effect of aging treatment on the fracture toughness and impact strength of injection moulded Ni-625 superalloy parts. Mater. Charact. 108, 8–15 (2015)

O. Ozgun, H.O. Gulsoy, R. Yilmaz, F. Findik, Injection molding of Nickel based 625 superalloy: sintering, heat treatment, microstructure and mechanical properties. J. Alloys Compd. 546, 192–207 (2013)

O. Ozgun, H.O. Gulsoy, F. Findik, R. Yilmaz, Microstructure and mechanical properties of Injection Moulded Nimonic-90 superalloy parts. Powder Metall. 55, 405–414 (2012)

L. Nastac, D.M. Stefanescu, Macrotransport-solidification kinetics modeling of equiaxed dendritic growth: part II. Computation problems and validation on Inconel-718 superalloy castings. Metall. Mater. Trans. A 27, 4075–4083 (1996)

J. Koutsky, High velocity oxy-fuel spraying. J. Mater. Process. Technol. 157, 557–560 (2004)

L.N. Moskowitz, Thermal spray: advances in coatings technology, in Proceedings of the 13th International Thermal Spray Conference, 1992, p. 611

M. Dorfman, J. DeFalco, J. Karthikeyan, Thermal spray: surface engineering via applied research, in Proceedings of the International Thermal Spray Conference, 1st, Montreal, QC, Canada, May 8–11, 2000, p 471

T.C. Totemeier, R.N. Wright, W.D. Swank, Mechanical and physical properties of high-velocity oxy-fuel-sprayed iron aluminide coatings. Metall. Mater. Trans. 34A, 2223–2231 (2003)

T.C. Totemeier, R.N. Wright, W.D. Swank, Microstructure and stresses in HVOF sprayed iron aluminide coatings. J. Therm. Spray Technol. 11, 400–408 (2002)

P. Siitonen, S.L. Chen, K. Niemi, P. Vuoristo, Electrochemical method for evaluating the corrosion resistance and porosity of thermal sprayed coatings, in Thermal Spray: International Advances in Coatings Technology, Proceedings of the International Thermal Spray Conference, 13th, 1992, p 853–858

P. Siitonen, T. Konos, P.O. Kettunen, Corrosion properties of stainless steel coatings made by different methods of thermal spraying, in Thermal Spray Industrial Applications, Proceedings of the National Thermal Spray Conference, 7th, 1994, p 105–110

B. Normand, H. Liao, O. Landemarre, C. Coddet, J. Pagetti, Thermal spray: meeting the challenges of the 21st century, in Proceedings of the International Thermal Spray Conference, 15th, Nice, May 25–29,1998, p 69

B. Normand, W. Herbin, O. Landemarre, C. Coddet, J. Pagetti, Electrochemical methods to the evaluation of thermal spray coatings corrosion resistance. Mater. Sci. Forum 289–292, 607 (1998)

D. Harvey, O. Lunder, R. Henriksen, Thermal spray: surface engineering via applied research, in Proceedings of the International Thermal Spray Conference, 1st, Montreal, QC, Canada, May 8–11, 2000, p 991

M.D.F. Harvey, A.J. Sturgeon, F.J. Blunt, S.B. Dunkerton, Thermal spraying: current status future trends, in Proceedings of the International Thermal Spraying Conference, 14th, 1995, p 531

D. Zhang, S.J. Harris, D.G. McCartney, Microstructure formation and corrosion behaviour in HVOF-sprayed Inconel 625 coatings. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 344(1–2), 45–46 (2003)

D. Chidambaram, C.R. Clayton, M.R. Dorfman, Evaluation of the electrochemical behavior of HVOF-sprayed alloy coatings—II. Surf. Coat. Technol. 192, 278–283 (2005)

J. Porcayo-Calderon, O. Sotelo-Mazon, V.M. Salinas-Bravo, C.D. Arrieta-Gonzalez, J.J. Ramos-Hernandez, C. Cuevas-Arteaga, Electrochemical performance of Ni20Cr coatings applied by combustion powder spray in ZnCl2-KCl molten salts. Int. J. Electrochem. Sci. 7, 1134–1148 (2012)

M.E. Aalamialeagha, S.J. Harri, M. Emamighomi, Influence of the HVOF spraying process on the microstructure and corrosion behaviour of Ni-20%Cr coatings. J. Mater. Sci. 38, 4587–4596 (2003)

C.S. Ramesh, D.S. Devaraj, R. Keshavamurthy, B.R. Sridhar, Slurry erosive wear behaviour of thermally sprayed Inconel 718 coatings by APS process. Wear 271, 1365–1371 (2011)

T. Sidhu, R. Agrawal, S. Prakash, Hot corrosion of some superalloys and role of high-velocity oxy-fuel spray coatings—a review. Surf. Coat. Technol. 198, 441–446 (2005)

ASTM E2109-0, Standard test methods for determining area percentage porosity in thermal sprayed coatings (ASTM International, West Conshohocken, 2014)

D. Chidambaram, C.R. Clayton, M.R. Dorfman, Evaluation of the electrochemical behavior of HVOF-sprayed alloy coatings. Surf. Coat. Technol. 176, 307–317 (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vasudev, H., Prashar, G., Thakur, L. et al. Electrochemical Corrosion Behavior and Microstructural Characterization of HVOF Sprayed Inconel-718 Coating on Gray Cast Iron. J Fail. Anal. and Preven. 21, 250–260 (2021). https://doi.org/10.1007/s11668-020-01057-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-01057-8