Abstract

Stem sealing plays an important role in valve operation, to avoid leakage from the valve stem area to the environment. Additionally, accuracy and tight sealing of stem seals are vital in fugitive emission applications where hazardous fluids such as gases or vapours may escape if a valve is not sealed properly. Soft thermoplastic and elastomer materials such as Teflon (PTFE), lip seal, V-pack, Viton as well as graphite or graphoil can be used for valve stem sealing. Appropriate stem sealing or packing depends on the process conditions where the valve will be used, including being able to withstand extreme temperatures, being resistant to aggressive fluid such as \({\text{H}}_{2}\)S containing fluid, displaying a low friction factor to the stem, providing very good sealing capability to prevent leakage from the valve stem area, and being adequately strong and economical. The sealing capability of compression packing is defined as the ability to expand laterally against the stem and stuffing box wall when stressed by tightening the gland. The stem sealing arrangement depends on the type of valves being used and the applications. The sealing capability and performance of a valve can be validated by testing the valve stem sealing through mechanical and temperature cycles based on different American Petroleum Institute standards or by finite element analysis. The torque required to operate a valve depends on parameters such as the packing or stem sealing material, number of stem sealing rings, load of gland flange, stem surface finish, temperature, and cycling. Reducing the number of packing rings can reduce the valve torque and the actuator sizing but removing rings can also increase the risk of leakage from the valve and reduce the effectiveness of the valve seals.

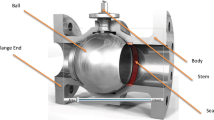

(Courtesy: Westad)

Similar content being viewed by others

References

B. Nesbitt, Handbook of Valves and Actuators: Valves Manual International, 1st edn. (Elsevier, Oxford, 2007)

P. Smit, R.W. Zappe, Valve Selection Handbook, 5th edn. (Elsevier, New York, 2004)

Trelleborg sealing solutions, Design Considerations for Subsea Valve Stem Seals. https://www.knowledgecenter.trelleborg.com/article/design-considerations-for-subsea-valve-stem-seals/ (2017). Accessed 2 Feb 2020

K. Sotoodeh, Piping and valve materials for offshore use, part 1. Stainl. Steel World Mag. 28(June), 40–44 (2016)

K. Sotoodeh, Piping and valve materials for offshore use, part 2. Stainl. Steel World Mag. 28(July/August), 35–40 (2016)

American Petroleum Institute (API), Specification for Pipeline and Piping Valves. API 6D, 24th edn. (API, Washington, DC, 2014)

International Organization for Organization (ISO), Pipeline Transportation Systems: Pipeline Valves. ISO 14313, 2nd edn. (ISO, Geneva, 2007)

K. Sotoodeh, Pipeline valves technology, material selection, welding, and stress analysis (A case study of a 30″ class 1500 pipeline ball valve). J. Pressure Vessel Technol. Paper No. PVT-18-1043. American Society of Mechanical Engineers (ASME). (2018). https://doi.org/10.1115/1.4040139

American Petroleum Institute (API), Type Testing of Rising Stem Valves Equipped with Flexible Graphite Packing for Fugitive Emissions. API 624, 1st edn. (API, Washington, DC, 2012)

International Organization for Organization (ISO), Industrial Valves—Measurement, Test, and Qualification Procedures for Fugitive Emissions. ISO 15848, 1st edn. (ISO, Geneva, 2006)

American Society of Mechanical Engineers (ASME), Process Piping. ASME B31.3 (ASME, New York, 2012)

NORSOK, Piping and Valves. NORSOK L-001, Revision 3 (NORSOK, Lysaker, 1999)

American Society of Mechanical Engineers (ASME), Valves—Flanged, Threaded, and Welding End. ASME B16.34 (ASME, New York, 2004)

NORSOK, Material Selection. NORSOK M-001, Revision 3 (NORSOK, Lysaker, 2002)

American Petroleum Institute (API), Butterfly Valves: Double Flanged, Lug- and Wafer-Type. API 609, 6th edn. (API, Washington, DC, 2004)

American Petroleum Institute (API), Type Testing of Process Valve Packing for Fugitive Emission. API 622, 2nd edn. (API, Washington, DC, 2011)

American Petroleum Institute (API), Type Testing of Rising Stem Valves Equipped with Packing for Fugitive Emission. API 624, 1st edn. (API, Washington, DC, 2014)

American Petroleum Institute (API) 6DSS, Specification for Subsea Pipeline Valves, 3rd edn. (API, Washington, DC, 2017)

American Petroleum Institute (API) 6A, Specification for Wellhead and Tree Equipment, 21st edn. (API, Washington, DC, 2018)

American Petroleum Institute (API) 17D, Design and Operation of Subsea Production Systems, Subsea Wellhead and Tree Equipment, 2nd edn. (API, Washington, DC, 2011)

K. Sotoodeh, A review on subsea process and valve technology. Springer J. Mar. Syst. Ocean Technol. (2019). https://doi.org/10.1007/s40868-019-00061-4

M. Diany, M. Mabrouki, J. Azouz, Finite element analysis of stuffing-box subjected to thermo-mechanical loads. J. Mech. Eng. Res. 1(01), 1–14 (2018)

A. Aksenov, K. Iliine, T. Luniewski, T. McArthy, F. Popielas, R. Ramkumar, Oil leakage through a valve stem seal, in ABAQUS Users’ Conference 2005 (2006)

NORSOK, Qualification of Non-metallic Sealing Materials and Manufacturers. NORSOK M-710, Revision 2 (NORSOK, Lysaker, 2001)

P.L. Skousen, Valve Handbook, 3rd edn. (McGraw-Hill Education, New York, 2011)

M.L. Nayyar, Piping Handbook, 7th edn. (McGraw-Hill Education, New York, 2000)

J. Drago, W. Evans, Gauging the force effects of stem packing on valve stem actuation. J. Proc. ASME/NC Pump Valve Symp. PVS2017-3518 (2017)

K. Sotoodeh, Actuator selection and sizing for valves. Springer J. Nat. Appl. Sci. (2019). https://doi.org/10.1007/s42452-019-1248-z

L.C. Zulaika, Torque increase due to heavy packing tightening in valves, in AMPO Valve World Conference 2016 (Dusseldorf, Germany, 2016)

Acknowledgements

I would like to express my gratitude to my partner, Ms. Tamara Zhunussova, for her great support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sotoodeh, K. A Review of Valve Stem Sealing to Prevent Leakage from the Valve and Its Effect on Valve Operation. J Fail. Anal. and Preven. 21, 9–16 (2021). https://doi.org/10.1007/s11668-020-01050-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-01050-1