Abstract

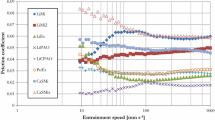

Two types of lithium greases were fabricated by using PAO and polyol ester as two base oils. The friction tests for the lithium soap-based greases were performed under different operating conditions by mini-traction machine, and the data were compared and analysed. The results show that when the lithium-based soap thickens different types of base oils with the same viscosity, the greater the elastohydrodynamic friction coefficient of the base oil, the greater the elastohydrodynamic friction coefficient of the grease. In a low-speed bearing or contact pair, both base oil and thickener go through the contact zone to contribute to the friction of the grease. When the same lithium-based thickener thickens the different base oils, the greater the interactions between the base oil molecules, the greater the interactions between the base oil molecules and the thickener molecules, the wider the soap fibres, and the greater the friction coefficient of the grease. The friction coefficient of oil PAO–lithium-based soap grease is higher than that of its base oil PAO. The friction coefficient of oil polyol ester–lithium-based soap grease is less than that of its base oil polyol ester when the viscosities of the two base oils are 68 mm2/s.

Similar content being viewed by others

References

Q.S. Sun, Lubricating Grease Properties and Its Applications (Hydrocarbon Processing Press, Beijing, 1989)

Y.B. Zhu, Technical Knowledge of Lubricating Grease, 3rd edn. (China Petrochemical Press, Beijing, 2015)

P.M. Lugt, A review on grease lubrication in rolling bearings. Tribol. Trans. 52(4), 470–480 (2009)

X.Q. Fan, W. Li et al., Probing the effect of thickener on tribological properties of lubricating greases. Tribol. Int. 118, 128–139 (2018)

Y.Q. Xia, Z.Z. Wen, X. Feng, Tribological properties of a lithium–calcium grease. Chem. Technol. Fuels Oils 51(1), 10–16 (2015)

J. Wang, X.C. Guo, Y. He et al., Tribological characteristics of graphene as grease additive under different contact forms. Tribol. Int. 127, 457–469 (2018)

R.K. Dixena, E. Sayanna, R.P. Badoni, A study on tribological behaviors of ZDDP in polymer thickened lubricating greases. Lubr. Sci. 28(3), 177–186 (2016)

N. Xu, W.M. Li, M. Zhang, X.B. Wang, Reinforcing effect of Lewis acid–base interaction on the high-temperature colloidal stability and tribological performance of lubricating grease. J. Ind. Eng. Chem. 46, 157–164 (2017)

P.P. Bai, S.W. Li et al., Tribological properties of liquid–metal galinstan as novel additive in lithium grease. Tribol. Int. 128, 181–189 (2018)

Q. He, A.L. Li et al., Tribological properties of nanometer cerium oxide as additives in lithium greases. Tribol. Int. 36(2), 209–214 (2018)

P.R. Wu, Y.C. Kong, Z.S. Ma et al., Preparation and tribological properties of novel zinc borate/MoS2 nanocomposites in grease. J. Alloys Compd. 740, 823–829 (2018)

Y.S. Wang, P. Li, J.W. Cao, J.W. Cheng, G. Li, A kind of ball-on-disc elastohydrodynamic friction test machine with hydraulic loading system: China, ZL201510063464.1, 09 June 2017

Y.S. Wang, S.C. Li, D. Guo, Study on rheological characteristics of a grease used in high speed bearing. China Pet. Process. Petrochem. Technol. 19(1), 55–62 (2017)

P.M. Cann, Grease degradation in a bearing simulation device. Tribol. Int. 39(12), 1698–1706 (2006)

D.E.P. Gonçalves, A.V. Campos, J.H.O. Seabra, An experimental study on starved grease lubricated contacts. Lubricants 82(6), 1–18 (2018)

Funding

The work is supported by the projects funded by the National Natural Science Foundation of China (51475143) and the National Natural Science Foundation of Tianjin, China (16JCYBJC18900).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Wu, B. Friction Characteristics and Mechanisms of Two Lithium Greases in Elastohydrodynamic Lubrication. J Fail. Anal. and Preven. 20, 1266–1273 (2020). https://doi.org/10.1007/s11668-020-00932-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00932-8