Abstract

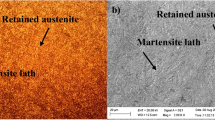

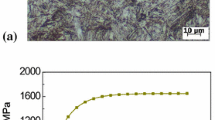

This paper presents a metallurgical failure analysis on failed material AISI 1020 bush used in industrial roller chains. This failure analysis study is carried out using the methodologies of metallographic analysis, scanning electron microscopy (SEM) analysis, chemical composition analysis and hardness analysis. In the inner diameter of the failed bush, numerous cracks originated and grew toward the outer diameter. The geometry of crack and surface fractures suggest failure is due to fatigue of impact. A quasicleavage significant feature occurred at the fracture surface very close to the crack initiation point. Simulation and experimental performance results of failed material (AISI 1020) and the proposed material (SAE 8620) are compared. The proposed material SAE 8620 has 233% higher crushing strength, 300% higher fatigue life cycles and 16.67% higher wear resistance compared to failed material AISI 1020. The conclusion presented is that alloy elements (chromium, nickel and molybdenum) in proposed SAE 8620 material significantly increase the performance of bush. Additionally, a roller chain with the proposed material SAE 8620 bush can be used for heavy shock load applications like mining drill rigs, balers, rotavators, construction loaders and combine harvesters.

Similar content being viewed by others

References

J.C. Conwell, G.E. Johnson, Experimental investigation of link tension and roller-sprocket impact in roller chain drives. Mech. Mach. Theory 3, 533–544 (1996)

American Chain Association, Standard Handbook of Chains: Chains for Power Transmission and Material Handling (2006)

R. Saito, N-Aki Noda, Y. Sano, J. Song, T. Minami, Y. Birou, A. Miyagi, Y. Huang, Fatigue strength analysis and fatigue damage evaluation of roller chain. Metals. 8(10), 1–15 (2018)

K. Krishnakuma, A. ArockiaSelvakumar, A review of failure analysis found in industrial roller chains. Int. J. ChemTech Res. 8(12), 598–603 (2015)

G. Pantazopoulos, A. Vazdirvanidis, A. Toulfatzis, A. Rikos, Fatigue failure of steel links operating as chain components in a heavy-duty drawbench. Eng. Fail. Anal. 16(7), 2440–2449 (2009)

A.L. Marcelo, R.C. Tokimatsu, I. Ferreira, Hydrogen embrittlement in an AISI 1045 steel component of the sugarcane industry. Eng. Fail. Anal. 16, 468–474 (2009)

C.R.F. Azevedo, D. Magarotto, Tschiptschin, A.P, Embrittlement of case hardened steel chain link, Engineering Failure Analysis, Vol 16 (No. 7), 2009, p 2311–2317

S.G. Sapate, V.K. Didolkar, Metallurgical investigation of failure of coal mill drag chain pin. Mater. Des. 30, 2623–2629 (2009)

G.A. Slabbert, J.J. Mcewan, R. Paton, Failure analysis of carrier chain pins. Eng. Fail. Anal. 5(2), 121–128 (2009)

M.D. Jagtap, D.B. Gaikwad, P.M. Pawar, Study of roller conveyor chain strip under tensile loading. Int. J. Mod. Eng. Res. 4(5), 61–66 (2014)

V. Wankhade, S. Sharma, A study on drag conveyor chain: How to prevent corrective maintenance in drag conveyors due to tensile loading. Indian J. Res. 4(4), 4–6 (2015)

D.M.M. Cardona, J. Wongsa-Ngam, H. Jimenez, T.G. Langdon, Effects on hardness and microstructure of AISI 1020 low-carbon steel processed by high-pressure torsion. J. Mater. Res. Technol. 6, 355–360 (2017)

A.P. Krelling, C.E. Costa, J.C.G. Milan, E.A.S. Almeidab, Micro-abrasive wear mechanisms of borided AISI 1020 steel. Tribol. Int. 111, 355–360 (2017)

Ilyas Turkmen, Emre Yalamaca, Mourad Keddam, Investigation of tribological behaviour and diffusion model of Fe2B layer formed by pack-boriding on SAE 1020 steel. Surf. Coat. Technol. 377, 1–12 (2019)

M. Musa, A.G. Mohammed, A. Muhammad, Wear properties of boron added high strength low alloy (HSLA) SAE 8620 steel. J. Metals Mater. Min. 28, 22–29 (2018)

M. Izciler, M. Tabur, Abrasive wear behavior of different case depth gas carburized AISI 8620 gear steel. Wear 260, 90–98 (2006)

M. Koyama, E. Akiyama, T. Sawaguchi, K. Ogawa IV, Y.I.Chumlyakov Kireeva, K. Tsuzaki, Hydrogen-assisted quasi-cleavage fracture in a single crystalline type 316 austenitic stainless steel. Corros. Sci. 75, 345–353 (2013)

Y. Zheng, W. Zeng, D. Li, H. Ma, P. Zhang, X. Ma, Quasi cleavage fracture of the bimodal size lamellar O phase microstructure of a Ti2AlNb based alloy. J. Alloys Compd. 799, 267–278 (2019)

KapilKhandelwal RaviKiran, A coupled microvoid elongation and dilation based ductile fracture model for structural steels. Eng. Fract. Mech. 145, 15–42 (2015)

J.Z. Lu, J.W. Zhong, K.Y. Luo, L. Zhang, F.Z. Dai, K.M. Chen, Q.W. Wang, J.S. Zhong, Y.K. Zhang, Micro-structural strengthening mechanism of multiple laser shock processing impacts on AISI 8620 steel. Mater. Sci. Eng. A 528, 6128–6133 (2011)

K. Krishnakumar, A. Arockia Selvakumar, Metallurgical investigation of failure analysis in industrial machine components. Mater. Today Proc. Article in press (2019)

U. Kanerva, T. Suhonen, J. Lagerbom, E. Levänen, Evaluation of crushing strength of spray-dried MgAl2O4 granule beds. Ceram. Int. 41, 8494–8500 (2015)

F. Geng, A.S.J. Suiker, An interface damage model for high-cycle fatigue. Eng. Fract. Mech. 221, 106644 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Krishnasamy, K., Arockia Doss, A.S. Metallurgical Failure Analysis and Improved Core Hardness to Enhance Crushing Strength, Wear Resistance and Fatigue Strength of Chain Bush. J Fail. Anal. and Preven. 20, 967–975 (2020). https://doi.org/10.1007/s11668-020-00896-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00896-9