Abstract

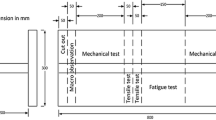

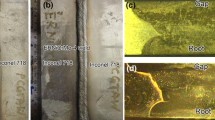

Hydroelectric power plants come into prominence worldwide day by day due to their low operating and maintenance costs, environment friendly structure and their use as renewable energy sources. In order to obtain maximum energy from such an important energy source, it is necessary to reduce downtime due to failures. One of the most important failures of hydroelectric power plants is the damage caused to the turbine wheel by cavitation. In this study, a sample with the same material as the turbine wheels of the hydroelectric power plants is provided. The effects of the hard fillet weld on the turbine wheel, which we have applied locally to this material, have been investigated both metallographically and physically. As a result of the research, it is observed that the main material and hard fillet weld are mostly compatible. The damages of the turbine wheel of the hydroelectric power plant have been repaired by applying the same method to the turbine wheel damaged by the cavitation. After 10,000 h of operation, the turbine wheel is inspected again. As a result, it has been determined that the hard fillet weld applied to the turbine wheel surface is resistant to the harmful effects of cavitation.

Similar content being viewed by others

References

F.M. White, Fluid Mechanics (2011)

A. Laouari, A. Ghenaiet, Simulations of Steady Cavitating Flow in a Small Francis Turbine. Int. J. Rotat. Mach. (2016). https://doi.org/10.1155/2016/4851454

U. Dorji, R. Ghomashchi, Hydro Turbine Failure Mechanisms. Eng. Fail. Anal. 44, 136–147 (2014). https://doi.org/10.1016/j.engfailanal.2014.04.013

M.K. Padhy, R.P. Saini, A Review on Silt Erosion in Hydro Turbines. Renew. Sustain. Energy 12, 1975–1986 (2007). https://doi.org/10.1016/j.rser.2007.01.025

X.W. Luo, B. Ji, Y. Tsujimoto, A Review of Cavitation in Hydraulic Machinery. J. Hydrodyn. 28, 335–358 (2016). https://doi.org/10.1016/s1001-6058(16)60638-8

H.S. Greval, H. Agrawal, H. Singh, Slurry Erosion Mechanism of Hydro turbine Steel: Effect of Operating Parameters. Tribol. Lett. 52, 1573–2711 (2013). https://doi.org/10.1007/s11249-013-0213-z

T. Cencic, M. Hocevar, B. Sirok, Study of Cavitation in Pump-Storage Hydro Power Plant Prototype, in 6th IAHR meeting of the Working Group “Cavitation and Dynamic Problems in Hydraulic Machinery and Systems”, Ljubljana, Slovenia, September (2015)

X. Escaler, E. Egusquiza, M. Farhat, F. Avellan, M. Coussirat, Detection of Cavitation in Hydraulic Turbines. Mech. Syst. Signal Process. 20, 983–1007 (2006). https://doi.org/10.1016/j.ymssp.2004.08.006

K. Celebioglu, B. Altintas, S. Aradag, Y. Tascioglu, Numerical Research of Cavitation on Francis Turbine Runners. Int. J. Hydrogen Energy 42(28), 17771–17781 (2017). https://doi.org/10.1016/j.ijhydene.2017.03.180

Q.N. Song, N. Xu, Y.F. Bao, Y.F. Jiang, W. Gu, Y.G. Zheng, Y.X. Qiao, Corrosion and Cavitation Erosion Behaviors of Two Marine Propeller Materials in Clean and Sulfide-Polluted 3.5% NaCl Solutions. Acta Metall. Sin. (English Letters) 30, 712–720 (2017). https://doi.org/10.1016/s40195-017-0602-7

V.E. Buchanan, P.H. Shipway, D.G. McCartney, Microstructure and Abrasive Wear Behavior of Shielded Metal Arc Welding Hardfacings Used in the Sugarcane Industry. Wear 263, 99–110 (2007). https://doi.org/10.1016/j.wear.2006.12.053

M.B. Santos, W.S. Labiapari, M.A.N. Ardila, W.M. da Silva, Jr., J.D.B. de Mello, Abrasion-Corrosion: New Insights from Force Measurements. Wear 332–333, 1206–1214 (2015). https://doi.org/10.1016/j.wear.2015.01.002

C. Liu, A. Leyland, Q. Bi, A. Matthews, Corrosion Resistance of Multi-layered Plasma-Assisted Physical Vapour Deposition TiN and CrN Coatings. Surf. Coat. Technol. 141, 164–173 (2001). https://doi.org/10.1016/S0257-8972(01)01267-1

S.H. Ahn, Y.S. Choi, J.G. Kim, J.G. Han, A Study on Corrosion Resistance Characteristics of PVD Cr-N Coated Steels by Electrochemical Method. Surf. Coat. Technol. 150, 319–326 (2002). https://doi.org/10.1016/S0257-8972(01)01529-8

A.N.J. Stevenson, I.M. Hutchings, Wear of Hardfacing White Cast Irons by Solid Particle Erosion. Wear 186–187, 150 (1995). https://doi.org/10.1016/0043-1648(95)07184-9

X. Wang, F. Han, S. Qu, Z. Zou, Microstructure of the Fe-Based Hardfacing Layers Reinforced by TiC-VC-Mo2C Particles. Surf. Coat. Technol. 202, 1502 (2008). https://doi.org/10.1016/surfcoat.2007.07.002

E.O. Correa, N.G. Alcantara, L.C. Valeriano, N.D. Barbedo, R.R. Chaves, The effect of Microstructure on Abrasive Wear of a Fe–Cr–C–Nb Hardfacing Alloy Deposited by the Open Arc Welding Process. Surf. Coat. Technol. 276, 479–484 (2015). https://doi.org/10.1016/j.surfcoat.2015.06.026

R. Gonzalez, M. Cadenas, R. Fernandez, J.L. Cortizo, E. Rodriguez, Wear Behaviour of Flame Sprayed NiCrBSi Coating Remelted by Flame or by Laser. Wear 262, 301–307 (2007). https://doi.org/10.1016/j.wear.2006.05.009

K. Gurumoorthy, M. Kamaraj, Rao K. Prasad, Rao A. Sambasiva, S. Venugopal, Microstructural Aspects of Plasma Transferred Arc Surfaced Ni-Based Hardfacing Alloy. Mater. Sci. Eng. A 456, 11–19 (2007). https://doi.org/10.1016/j.msea.2006.12.121

R.J. Chung, X. Tang, D.Y. Li, B. Hinckley, K. Dolman, Microstructure Refinement of Hypereutectic High Cr Cast Irons Using Hard Carbide-Forming Elements for Improved Wear Resistance. Wear 301, 69706 (2013). https://doi.org/10.1016/j.wear.2013.01.079

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kahraman, G., Taşgin, Y. Application of Local Hard Fillet Weld to Repair Damage Caused by Cavitation in Hydroelectric Power Plant. J Fail. Anal. and Preven. 20, 912–919 (2020). https://doi.org/10.1007/s11668-020-00892-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00892-z