Abstract

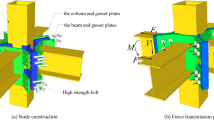

In the present work, the activity of analyzing the breaking of the steerer tube of a bicycle is presented. After a description of the steering assembly of the bicycle, the problem is presented. The problem consists in the fact that the fork which consists of a head a steerer tube and 2 stems that make up the fork has a clear break at the junction between the head of the fork and the tube. The section has a typical case of fatigue failure. In fact, about three quarters of the section are hammered, while the remaining part is ripped. Then the observation under the electron microscope is presented for better understanding what was the real state of the surface of the fracture section of the tube, and then it presents the observation activity to the scanning electron microscope in order to identify the composition of the metallic material in order to check whether there is a discontinuity in the composition of the material. Finally, a structural-type finite element analysis is carried out to verify which was the stress state at the level of the breaking section. It results that given the open conformation of the tube, the geometrical discontinuity due to the opening creates a peak of tension that goes to about 1000 MPa which is sufficient to trigger a crack for fatigue failure. An estimation fatigue life of the joint was carried out and was demonstrated that the life duration had a reduction from unlimited to about 2500 cycles due to the presence of the notch. This way it was shown that the conformation of the tube was the cause of triggering the fatigue break.

Similar content being viewed by others

References

C.N. Madivalar, T. Shay, S. Kolekar, Fatigue failure analysis of bike crank arm using solidworks simulation. J. Mech. Eng. Res. Dev. 41(3), 9–13 (2018). https://doi.org/10.26480/jmerd.03.2018.09.13

K. Triyono, S. Kaleg, N. Adyono, The failure analysis of bike brake lever: observation on crack propagation and stress analysis. AIP Conf. Proc. 2097, 030070 (2019). https://doi.org/10.1063/1.5098245

H. Shelton, J.O. Sullivan, K. Gall, Analysis of the fatigue failure of a mountain bike front shock. Eng. Fail. Anal. 11(3), 375–386 (2004). https://doi.org/10.1016/j.engfailanal.2003.06.002

Y. Lu, H. Chen, X.Fatigue He, Fatigue failure probabilistic estimation of electric bike shock absorber. Zhendong Ceshi Yu Zhenduan/J. Vib. Meas. Diagn. 25(4), 296–298 (2005)

M. G. Antonelli, W. D’Ambrogio, F. Durante, Development of a pneumatic soft actuator as a hand finger for a collaborative robot, in Proceedings of the 2018 2nd International Conference on Mechatronics Systems and Control Engineering, ICMSCE 2018, February 21–23, 2018, Amsterdam, Netherlands (ACM, New York, NY, 2018), pp. 67–71

M.G. Antonelli, P. Beomonte Zobel, F. Durante et al., Numerical modelling and experimental validation of a McKibben pneumatic muscle actuator. J. Intell. Mater. Syst. Struct. 28(19), 2737–2748 (2017)

F. Durante, M.G. Antonelli, P. Beomonte Zobel et al., Development of a straight fibers pneumatic muscle. Int. J. Autom. Technol. 12(3), 413–423 (2018)

M.G. Antonelli, P. Beomonte Zobel, W. D’Ambrogio et al., An analytical formula for designing McKibben pneumatic muscles. Int. J. Mech. Eng. Technol. 9(12), 320–337 (2018)

E. D’Amato, F. Durante, W. D’Ambrogio, Distributed structural modification using local interface model, in Proceedings of the 2002 International Conference on Noise and Vibration Engineering, ISMA (2002), pp. 1731–1739

E. D’Amato, F. Durante, G. Fedele, Numerical and experimental analyses of the structural behaviour of braided composite materials. Key Eng. Mater. 144, 293–300 (1998)

T. Raparelli, P.B. Zobel, F. Durante, A proposed methodology for the development of microgrippers: an application to a silicon device actuated by shape memory alloy wires. Int. J. Mech. Eng. Technol. 9(2), 235–249 (2018)

N. Koceska, S. Koceski, P.B. Zobel, F. Durante, Control architecture for a lower limbs rehabilitation robot system, in 2008 IEEE International Conference on Robotics and Biomimetics, ROBIO 2008, Art. No. 4913131 (2009), pp. 971–976. https://doi.org/10.1109/robio.2009.4913131

E. Panero, G.G. Muscolo, L. Gastaldi, S. Pastorelli, Multibody analysis of a 3D human model with trunk exoskeleton for industrial applications. Comput. Methods Appl. Sci. 53, 43–51 (2020). https://doi.org/10.1007/978-3-030-23132-3_6

N. Koceska, S. Koceski, F. Durante, P.B. Zobel, T. Raparelli, Control architecture of a 10 DOF lower limbs exoskeleton for gait rehabilitation. Int. J. Adv. Robot. Syst. 10, 68 (2013). https://doi.org/10.5772/55032

S. Pheasant, Body Space: Anthropometry, Ergonomics and Design (Taylor Francis, London, 1986)

R. Drillis, R. Contini, Body Segment Parameters (Office of Vocational Rehabilitation, New York, 1966). Report No. 1166-03

F. Durante, M.G. Antonelli, P.B. Zobel, Development of an active exoskeleton for assisting back movements in lifting weights. Int. J. Mech. Eng. Robot. Res. 7(4), 353–360 (2018)

F. Durante, Tools and biomechanical modeling use in legal disputes: some case studies. Front. Bioeng. Biotechnol. 7, 429 (2019). https://doi.org/10.3389/fbioe.2019.00429

J.E. Shigley, C.R. Mischke, Mechanical Engineering Design, 5th edn. (McGraw-Hill, London, 1989)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Durante, F. Failure Analysis of the Steerer Tube of a Bike. J Fail. Anal. and Preven. 20, 755–767 (2020). https://doi.org/10.1007/s11668-020-00873-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00873-2